正在加载图片...

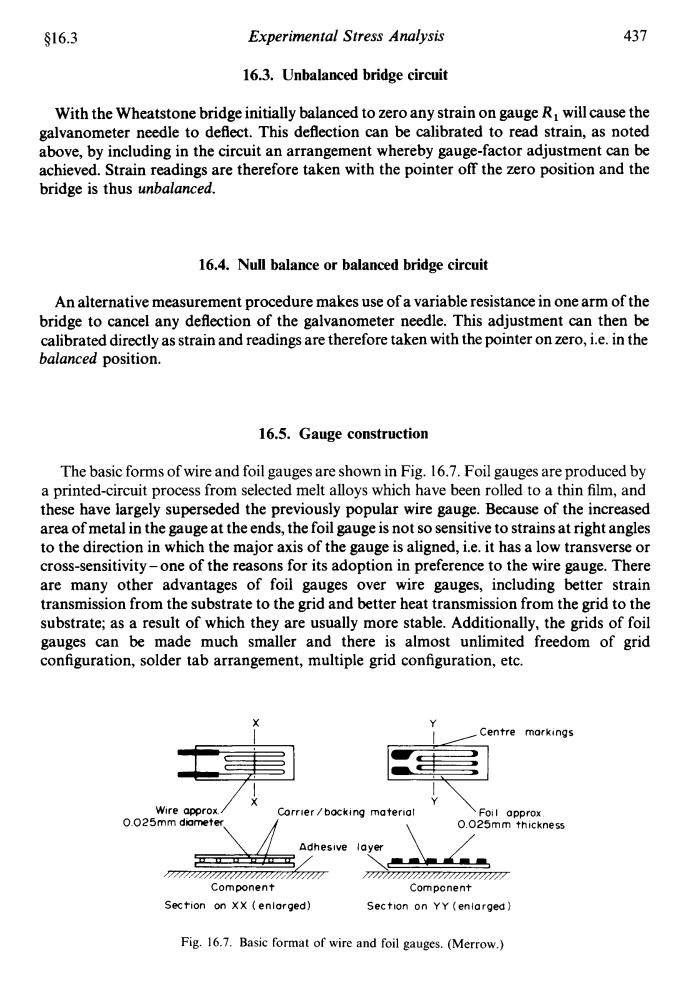

S16.3 Experimental Stress Analysis 437 16.3.Unbalanced bridge circuit With the Wheatstone bridge initially balanced to zero any strain on gauge R will cause the galvanometer needle to deflect.This deflection can be calibrated to read strain,as noted above,by including in the circuit an arrangement whereby gauge-factor adjustment can be achieved.Strain readings are therefore taken with the pointer off the zero position and the bridge is thus unbalanced. 16.4.Null balance or balanced bridge circuit An alternative measurement procedure makes use of a variable resistance in one arm of the bridge to cancel any deflection of the galvanometer needle.This adjustment can then be calibrated directly as strain and readings are therefore taken with the pointer on zero,i.e.in the balanced position. 16.5.Gauge construction The basic forms of wire and foil gauges are shown in Fig.16.7.Foil gauges are produced by a printed-circuit process from selected melt alloys which have been rolled to a thin film,and these have largely superseded the previously popular wire gauge.Because of the increased area of metal in the gauge at the ends,the foil gauge is not so sensitive to strains at right angles to the direction in which the major axis of the gauge is aligned,i.e.it has a low transverse or cross-sensitivity-one of the reasons for its adoption in preference to the wire gauge.There are many other advantages of foil gauges over wire gauges,including better strain transmission from the substrate to the grid and better heat transmission from the grid to the substrate;as a result of which they are usually more stable.Additionally,the grids of foil gauges can be made much smaller and there is almost unlimited freedom of grid configuration,solder tab arrangement,multiple grid configuration,etc. Centre morkings Wire approx. Corrier /backing materia Foil approx. O.025mm diameter 0.025mm thickness Adhesive layer 7P7777Z7 Component Compenent Section on XX (enlarged) Section on YY (enlarged) Fig.16.7.Basic format of wire and foil gauges.(Merrow.)416.3 Experimental Stress Analysis 437 16.3. Unbalanced bridge circuit With the Wheatstone bridge initially balanced to zero any strain on gauge R, will cause the galvanometer needle to deflect. This deflection can be calibrated to read strain, as noted above, by including in the circuit an arrangement whereby gauge-factor adjustment can be achieved. Strain readings are therefore taken with the pointer off the zero position and the bridge is thus unbalanced. 16.4. Null balance or balanced bridge circuit An alternative measurement procedure makes use of a variable resistance in one arm of the bridge to cancel any deflection of the galvanometer needle. This adjustment can then be calibrated directly as strain and readings are therefore taken with the pointer on zero, i.e. in the balanced position. 16.5. Gauge construction The basic forms of wire and foil gauges are shown in Fig. 16.7. Foil gauges are produced by a printed-circuit process from selected melt alloys which have been rolled to a thin film, and these have largely superseded the previously popular wire gauge. Because of the increased area of metal in the gauge at the ends, the foil gauge is not so sensitive to strains at right angles to the direction in which the major axis of the gauge is aligned, i.e. it has a low transverse or cross-sensitivity -one of the reasons for its adoption in preference to the wire gauge. There are many other advantages of foil gauges over wire gauges, including better strain transmission from the substrate to the grid and better heat transmission from the grid to the substrate; as a result of which they are usually more stable. Additionally, the grids of foil gauges can be made much smaller and there is almost unlimited freedom of grid configuration, solder tab arrangement, multiple grid configuration, etc. X Y I ,Centre markings Y Wire approx / x Corrier/backing material 0 025rnm dometer. A \ 0 025mm thickness Component v Corn pcnent Section on XX (enlarged) Section on YY (enlarged) Fig. 16.7. Basic format of wire and foil gauges. (Merrow.)