正在加载图片...

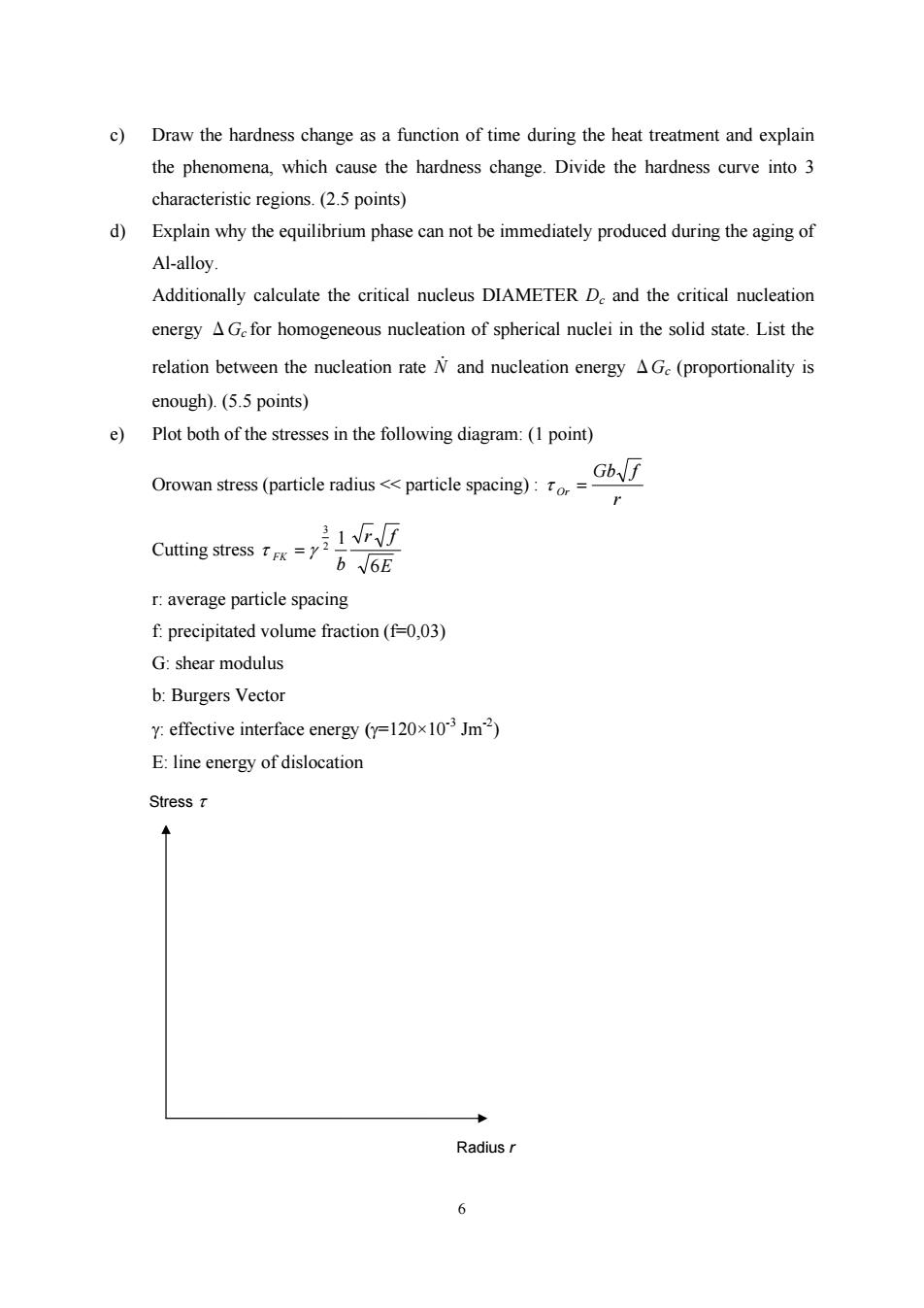

c)Draw the hardness change as a function of time during the heat treatment and explain the phenomena,which cause the hardness change.Divide the hardness curve into 3 characteristic regions.(2.5 points) d)Explain why the equilibrium phase can not be immediately produced during the aging of Al-alloy Additionally calculate the critical nucleus DIAMETER D and the critical nucleation energy A Ge for homogeneous nucleation of spherical nuclei in the solid state.List the relation between the nucleation rate N and nucleation energy AGe(proportionality is enough).(5.5 points) e)Plot both of the stresses in the following diagram:(1 point) Gb Orowan stress(particle radius<<particle spacing):Tor=- F Cutting stress T =y2 b6E r:average particle spacing f:precipitated volume fraction (f-0,03) G:shear modulus b:Burgers Vector Y:effective interface energy (y=120x103 Jm2) E:line energy of dislocation Stress r Radius r 66 c) Draw the hardness change as a function of time during the heat treatment and explain the phenomena, which cause the hardness change. Divide the hardness curve into 3 characteristic regions. (2.5 points) d) Explain why the equilibrium phase can not be immediately produced during the aging of Al-alloy. Additionally calculate the critical nucleus DIAMETER Dc and the critical nucleation energy ΔGc for homogeneous nucleation of spherical nuclei in the solid state. List the relation between the nucleation rate N& and nucleation energy ΔGc (proportionality is enough). (5.5 points) e) Plot both of the stresses in the following diagram: (1 point) Orowan stress (particle radius << particle spacing) : τ Or Gb f r = Cutting stress τ γ FK b r f E = 3 2 1 6 r: average particle spacing f: precipitated volume fraction (f=0,03) G: shear modulus b: Burgers Vector γ: effective interface energy (γ=120×10-3 Jm-2) E: line energy of dislocation Radius r Stress τ