正在加载图片...

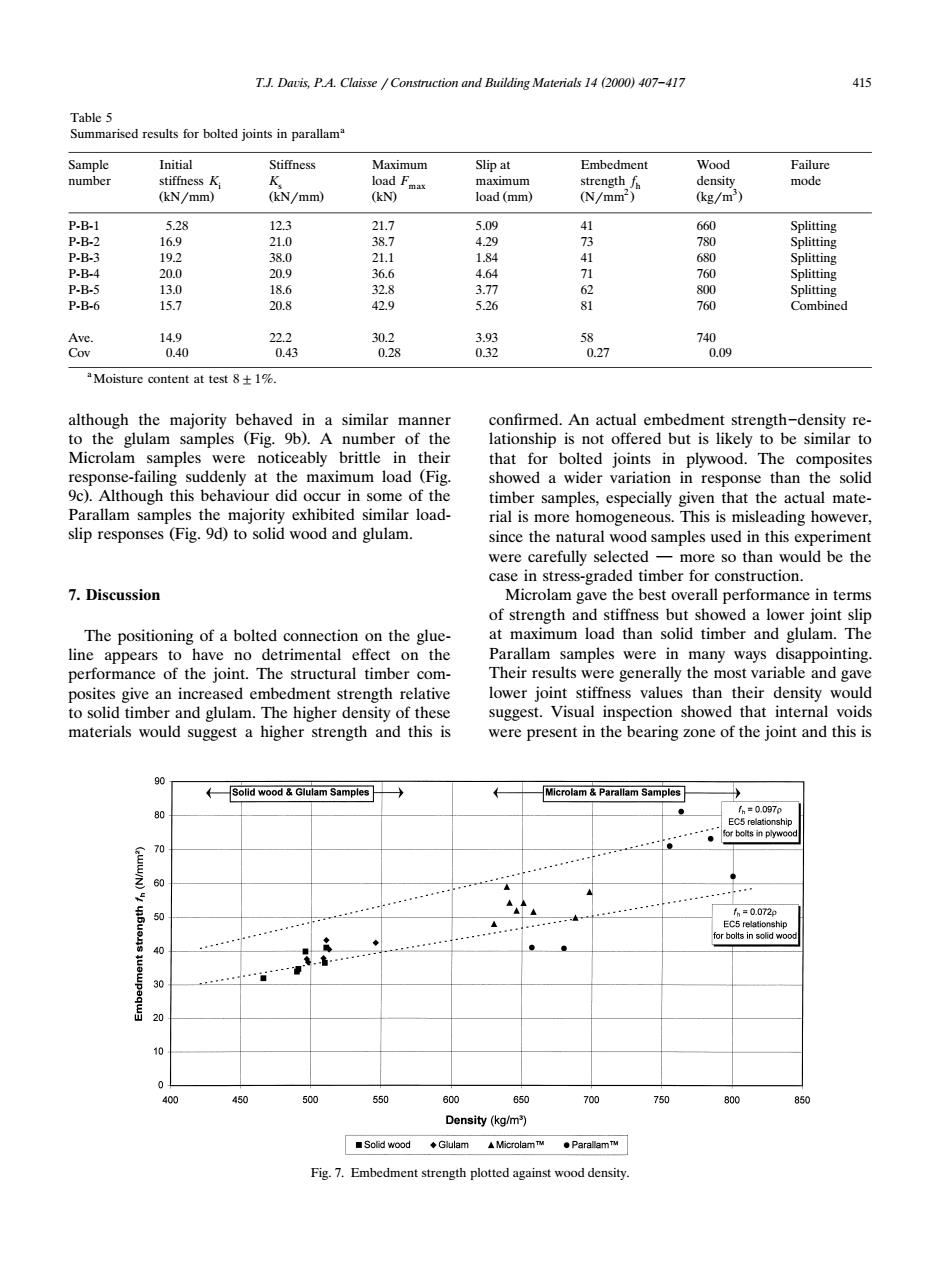

nd Building Materials14(200)407-417 nitial (kN/mm) 207 0 474 76 品 33 74 .09 "Moisture content at test 8+1%. although the majority behaved in a similar manner confirmed.An actual embedment strength-density re lationship is not offered but is likely to be similar to 9c).Although this behaviour did occur in some of the rial is more homogeneous.This is misleading however. since the natural wood samples used in this experiment more so than would be the 7.Discussion o in t of strength and stifmess but showed a lower joint sli The positioning of a bolted connection on the glue at maximum load than solid timber and glulam.The effect on the Parallam samples were in joi structur com neir re re gene and ga materials would suggest a higher strength and this is were present in the bearing zone of the joint and this is AA -024 40 30 550 500 66 700 Density (kg/m) Fig.7.Embedment strength plotted against wood density.T.J. Da¨is, P.A. Claisse rConstruction and Building Materials 14 2000 407 ( ) ]417 415 Table 5 a Summarised results for bolted joints in parallam Sample Initial Stiffness Maximum Slip at Embedment Wood Failure number stiffness K K load F maximum strength f density mode i s max h 2 3 Ž . Ž . Ž. Ž . Ž . Ž . kNrmm kNrmm kN load mm Nrmm kgrm P-B-1 5.28 12.3 21.7 5.09 41 660 Splitting P-B-2 16.9 21.0 38.7 4.29 73 780 Splitting P-B-3 19.2 38.0 21.1 1.84 41 680 Splitting P-B-4 20.0 20.9 36.6 4.64 71 760 Splitting P-B-5 13.0 18.6 32.8 3.77 62 800 Splitting P-B-6 15.7 20.8 42.9 5.26 81 760 Combined Ave. 14.9 22.2 30.2 3.93 58 740 Cov 0.40 0.43 0.28 0.32 0.27 0.09 a Moisture content at test 8"1%. although the majority behaved in a similar manner to the glulam samples Fig. 9b . A number of the Ž . Microlam samples were noticeably brittle in their response-failing suddenly at the maximum load Fig. Ž 9c . Although this behaviour did occur in some of the . Parallam samples the majority exhibited similar loadslip responses Fig. 9d to solid wood and glulam. Ž . 7. Discussion The positioning of a bolted connection on the glueline appears to have no detrimental effect on the performance of the joint. The structural timber composites give an increased embedment strength relative to solid timber and glulam. The higher density of these materials would suggest a higher strength and this is confirmed. An actual embedment strength]density relationship is not offered but is likely to be similar to that for bolted joints in plywood. The composites showed a wider variation in response than the solid timber samples, especially given that the actual material is more homogeneous. This is misleading however, since the natural wood samples used in this experiment were carefully selected } more so than would be the case in stress-graded timber for construction. Microlam gave the best overall performance in terms of strength and stiffness but showed a lower joint slip at maximum load than solid timber and glulam. The Parallam samples were in many ways disappointing. Their results were generally the most variable and gave lower joint stiffness values than their density would suggest. Visual inspection showed that internal voids were present in the bearing zone of the joint and this is Fig. 7. Embedment strength plotted against wood density