正在加载图片...

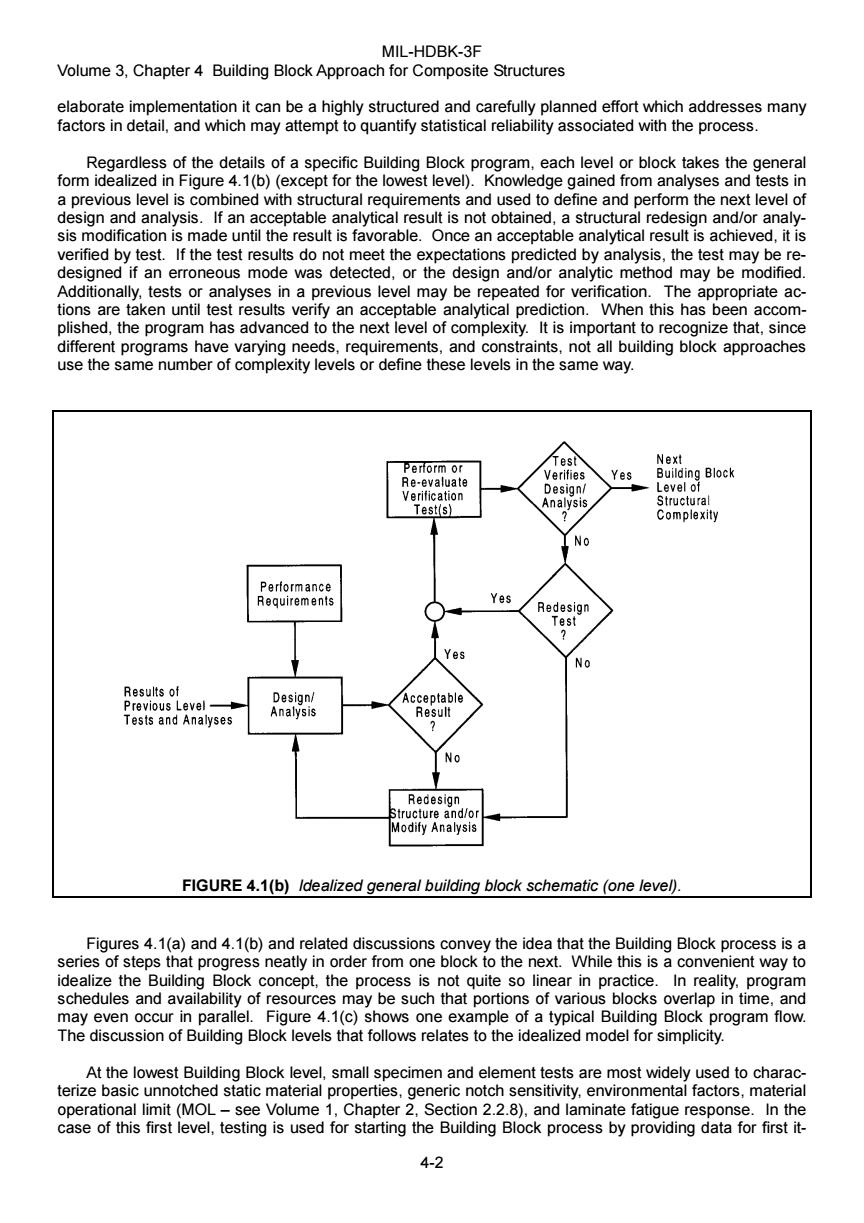

MIL-HDBK-3F Volume 3,Chapter 4 Building Block Approach for Composite Structures elaborate implementation it can be a highly structured and carefully planned effort which addresses many factors in detail,and which may attempt to quantify statistical reliability associated with the process Regardless of the details of a specific Building Block program,each level or block takes the general form idealized in Figure 4.1(b)(except for the lowest level).Knowledge gained from analyses and tests in a previous level is combined with structural requirements and used to define and perform the next level of design and analysis.If an acceptable analytical result is not obtained,a structural redesign and/or analy- sis modification is made until the result is favorable.Once an acceptable analytical result is achieved,it is verified by test.If the test results do not meet the expectations predicted by analysis,the test may be re- designed if an erroneous mode was detected,or the design and/or analytic method may be modified. Additionally,tests or analyses in a previous level may be repeated for verification.The appropriate ac- tions are taken until test results verify an acceptable analytical prediction.When this has been accom- plished,the program has advanced to the next level of complexity.It is important to recognize that,since different programs have varying needs,requirements,and constraints,not all building block approaches use the same number of complexity levels or define these levels in the same way. Next Perform or Test Verifies Yes Building Block Re-evaluate Design/ Level of Verification Analysis Structural Test(s) 7 Complexity No Performance Requirements Yes Redesign Test Yes o Results of Design/ Acceptable Previous Level 、 Tests and Analyses Analysis Result No Redesign Structure and/or Modify Analysis FIGURE 4.1(b)Idealized general building block schematic(one level). Figures 4.1(a)and 4.1(b)and related discussions convey the idea that the Building Block process is a series of steps that progress neatly in order from one block to the next.While this is a convenient way to idealize the Building Block concept,the process is not quite so linear in practice.In reality.program schedules and availability of resources may be such that portions of various blocks overlap in time,and may even occur in parallel.Figure 4.1(c)shows one example of a typical Building Block program flow. The discussion of Building Block levels that follows relates to the idealized model for simplicity. At the lowest Building Block level,small specimen and element tests are most widely used to charac- terize basic unnotched static material properties,generic notch sensitivity,environmental factors,material operational limit (MOL-see Volume 1,Chapter 2,Section 2.2.8),and laminate fatigue response.In the case of this first level,testing is used for starting the Building Block process by providing data for first it- 4-2MIL-HDBK-3F Volume 3, Chapter 4 Building Block Approach for Composite Structures 4-2 elaborate implementation it can be a highly structured and carefully planned effort which addresses many factors in detail, and which may attempt to quantify statistical reliability associated with the process. Regardless of the details of a specific Building Block program, each level or block takes the general form idealized in Figure 4.1(b) (except for the lowest level). Knowledge gained from analyses and tests in a previous level is combined with structural requirements and used to define and perform the next level of design and analysis. If an acceptable analytical result is not obtained, a structural redesign and/or analysis modification is made until the result is favorable. Once an acceptable analytical result is achieved, it is verified by test. If the test results do not meet the expectations predicted by analysis, the test may be redesigned if an erroneous mode was detected, or the design and/or analytic method may be modified. Additionally, tests or analyses in a previous level may be repeated for verification. The appropriate actions are taken until test results verify an acceptable analytical prediction. When this has been accomplished, the program has advanced to the next level of complexity. It is important to recognize that, since different programs have varying needs, requirements, and constraints, not all building block approaches use the same number of complexity levels or define these levels in the same way. FIGURE 4.1(b) Idealized general building block schematic (one level). Figures 4.1(a) and 4.1(b) and related discussions convey the idea that the Building Block process is a series of steps that progress neatly in order from one block to the next. While this is a convenient way to idealize the Building Block concept, the process is not quite so linear in practice. In reality, program schedules and availability of resources may be such that portions of various blocks overlap in time, and may even occur in parallel. Figure 4.1(c) shows one example of a typical Building Block program flow. The discussion of Building Block levels that follows relates to the idealized model for simplicity. At the lowest Building Block level, small specimen and element tests are most widely used to characterize basic unnotched static material properties, generic notch sensitivity, environmental factors, material operational limit (MOL – see Volume 1, Chapter 2, Section 2.2.8), and laminate fatigue response. In the case of this first level, testing is used for starting the Building Block process by providing data for first it-