正在加载图片...

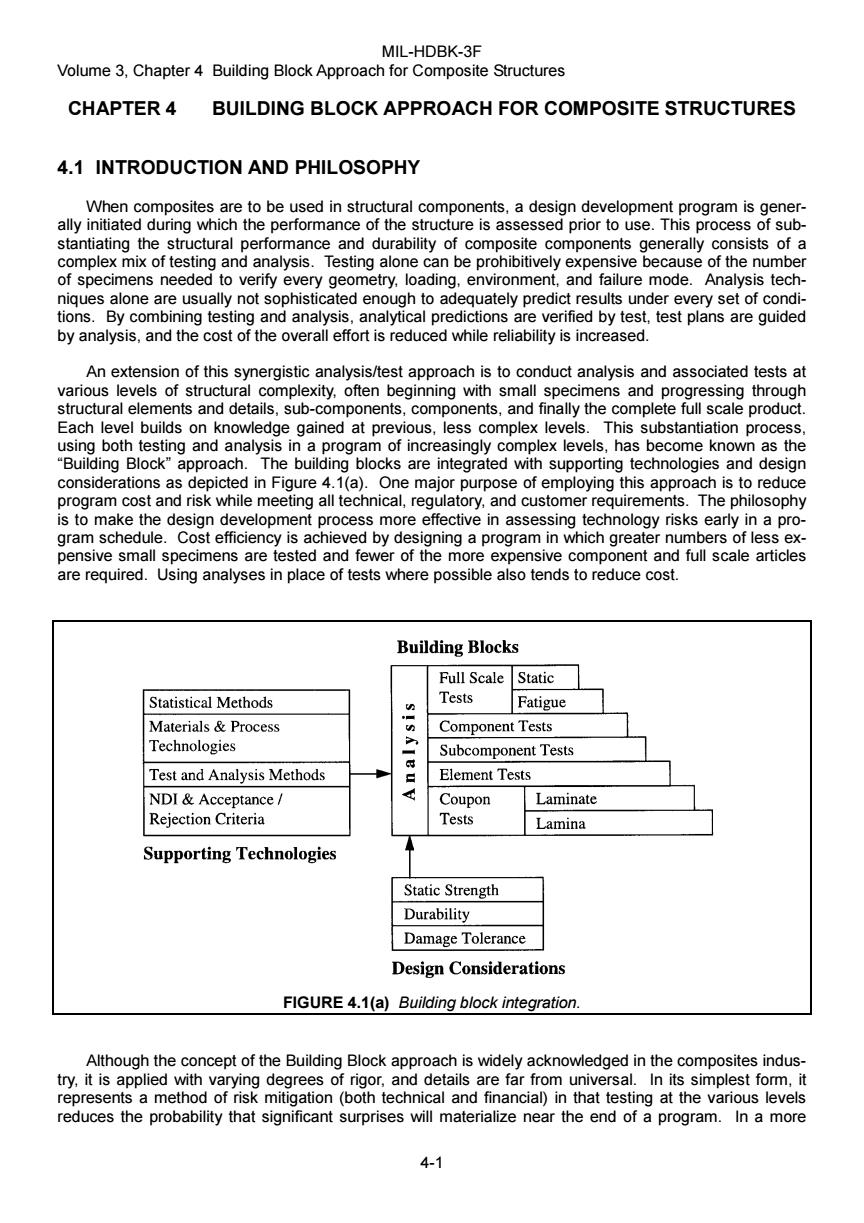

MIL-HDBK-3F Volume 3,Chapter 4 Building Block Approach for Composite Structures CHAPTER 4 BUILDING BLOCK APPROACH FOR COMPOSITE STRUCTURES 4.1 INTRODUCTION AND PHILOSOPHY When composites are to be used in structural components,a design development program is gener- ally initiated during which the performance of the structure is assessed prior to use.This process of sub- stantiating the structural performance and durability of composite components generally consists of a complex mix of testing and analysis.Testing alone can be prohibitively expensive because of the number of specimens needed to verify every geometry,loading,environment,and failure mode.Analysis tech- niques alone are usually not sophisticated enough to adequately predict results under every set of condi- tions.By combining testing and analysis,analytical predictions are verified by test,test plans are guided by analysis,and the cost of the overall effort is reduced while reliability is increased. An extension of this synergistic analysis/test approach is to conduct analysis and associated tests at various levels of structural complexity,often beginning with small specimens and progressing through structural elements and details,sub-components,components,and finally the complete full scale product. Each level builds on knowledge gained at previous,less complex levels.This substantiation process, using both testing and analysis in a program of increasingly complex levels,has become known as the "Building Block"approach.The building blocks are integrated with supporting technologies and design considerations as depicted in Figure 4.1(a).One major purpose of employing this approach is to reduce program cost and risk while meeting all technical,regulatory,and customer requirements.The philosophy is to make the design development process more effective in assessing technology risks early in a pro- gram schedule.Cost efficiency is achieved by designing a program in which greater numbers of less ex- pensive small specimens are tested and fewer of the more expensive component and full scale articles are required.Using analyses in place of tests where possible also tends to reduce cost. Building Blocks Full Scale Static Statistical Methods Tests Fatigue Materials Process Component Tests Technologies Subcomponent Tests Test and Analysis Methods 日 Element Tests NDI Acceptance/ Coupon Laminate Rejection Criteria Tests Lamina Supporting Technologies Static Strength Durability Damage Tolerance Design Considerations FIGURE 4.1(a)Building block integration. Although the concept of the Building Block approach is widely acknowledged in the composites indus- try,it is applied with varying degrees of rigor,and details are far from universal.In its simplest form,it represents a method of risk mitigation (both technical and financial)in that testing at the various levels reduces the probability that significant surprises will materialize near the end of a program.In a more 4-1MIL-HDBK-3F Volume 3, Chapter 4 Building Block Approach for Composite Structures 4-1 CHAPTER 4 BUILDING BLOCK APPROACH FOR COMPOSITE STRUCTURES 4.1 INTRODUCTION AND PHILOSOPHY When composites are to be used in structural components, a design development program is generally initiated during which the performance of the structure is assessed prior to use. This process of substantiating the structural performance and durability of composite components generally consists of a complex mix of testing and analysis. Testing alone can be prohibitively expensive because of the number of specimens needed to verify every geometry, loading, environment, and failure mode. Analysis techniques alone are usually not sophisticated enough to adequately predict results under every set of conditions. By combining testing and analysis, analytical predictions are verified by test, test plans are guided by analysis, and the cost of the overall effort is reduced while reliability is increased. An extension of this synergistic analysis/test approach is to conduct analysis and associated tests at various levels of structural complexity, often beginning with small specimens and progressing through structural elements and details, sub-components, components, and finally the complete full scale product. Each level builds on knowledge gained at previous, less complex levels. This substantiation process, using both testing and analysis in a program of increasingly complex levels, has become known as the “Building Block” approach. The building blocks are integrated with supporting technologies and design considerations as depicted in Figure 4.1(a). One major purpose of employing this approach is to reduce program cost and risk while meeting all technical, regulatory, and customer requirements. The philosophy is to make the design development process more effective in assessing technology risks early in a program schedule. Cost efficiency is achieved by designing a program in which greater numbers of less expensive small specimens are tested and fewer of the more expensive component and full scale articles are required. Using analyses in place of tests where possible also tends to reduce cost. FIGURE 4.1(a) Building block integration. Although the concept of the Building Block approach is widely acknowledged in the composites industry, it is applied with varying degrees of rigor, and details are far from universal. In its simplest form, it represents a method of risk mitigation (both technical and financial) in that testing at the various levels reduces the probability that significant surprises will materialize near the end of a program. In a more