正在加载图片...

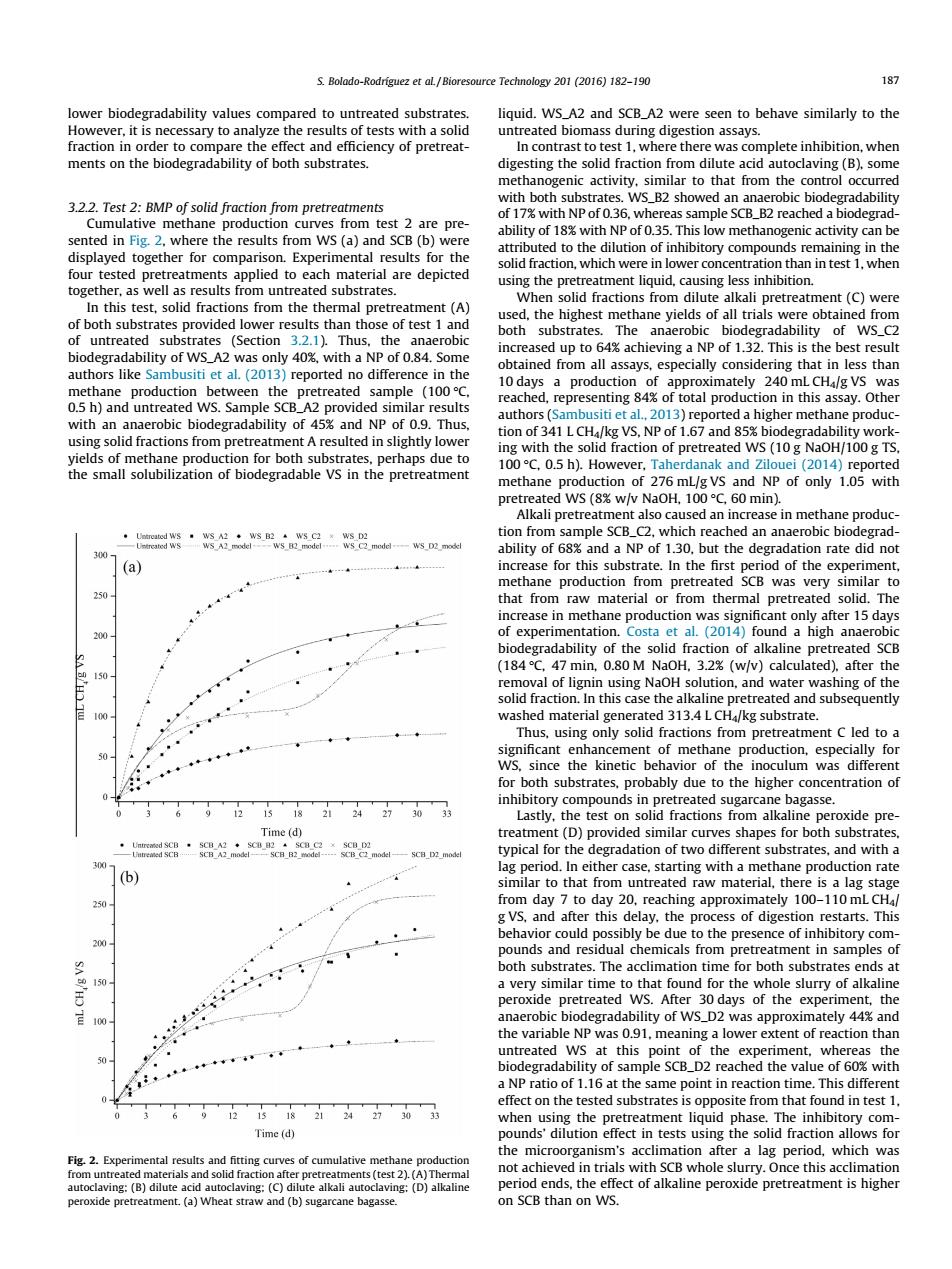

S.Bolado-Rodriguez et aL/Bioresource Technology 201(2016)182-190 187 lower biodegradability values compared to untreated substrates. liquid.WS_A2 and SCB_A2 were seen to behave similarly to the However,it is necessary to analyze the results of tests with a solid untreated biomass during digestion assays. fraction in order to compare the effect and efficiency of pretreat- In contrast to test 1,where there was complete inhibition,when ments on the biodegradability of both substrates. digesting the solid fraction from dilute acid autoclaving(B),some methanogenic activity,similar to that from the control occurred with both substrates.WS_B2 showed an anaerobic biodegradability 3.2.2.Test 2:BMP of solid fraction from pretreatments of 17%with NP of 0.36,whereas sample SCB_B2 reached a biodegrad- Cumulative methane production curves from test 2 are pre- ability of 18%with NP of 0.35.This low methanogenic activity can be sented in Fig.2,where the results from WS(a)and SCB(b)were attributed to the dilution of inhibitory compounds remaining in the displayed together for comparison.Experimental results for the solid fraction,which were in lower concentration than in test 1,when four tested pretreatments applied to each material are depicted using the pretreatment liquid,causing less inhibition. together,as well as results from untreated substrates. When solid fractions from dilute alkali pretreatment (C)were In this test,solid fractions from the thermal pretreatment (A) used,the highest methane yields of all trials were obtained from of both substrates provided lower results than those of test 1 and both of untreated substrates (Section 3.2.1).Thus,the anaerobic substrates.The anaerobic biodegradability of WS_C2 increased up to 64%achieving a NP of 1.32.This is the best result biodegradability of WS_A2 was only 40%,with a NP of 0.84.Some obtained from all assays,especially considering that in less than authors like Sambusiti et al.(2013)reported no difference in the methane production between the pretreated sample (100C. 10 days a production of approximately 240 mL CHa/g VS was reached,representing 84%of total production in this assay.Other 0.5 h)and untreated WS.Sample SCB_A2 provided similar results authors(Sambusiti et al.,2013)reported a higher methane produc- with an anaerobic biodegradability of 45%and NP of 0.9.Thus. tion of 341 L CH4/kg VS,NP of 1.67 and 85%biodegradability work- using solid fractions from pretreatment A resulted in slightly lower ing with the solid fraction of pretreated WS(10g NaOH/100 g TS. yields of methane production for both substrates,perhaps due to 100C,0.5 h).However,Taherdanak and Zilouei (2014)reported the small solubilization of biodegradable VS in the pretreatment methane production of 276 mL/g VS and NP of only 1.05 with pretreated WS(8%w/v NaOH,100C,60 min). Alkali pretreatment also caused an increase in methane produc- eated WSwsA2,wsB24WC2wsD2 tion from sample SCB_C2,which reached an anaerobic biodegrad- Ws C2 medel---WS_D2_modcl 300- ability of 68%and a NP of 1.30.but the degradation rate did not (a) increase for this substrate.In the first period of the experiment, methane production from pretreated SCB was very similar to that from raw material or from thermal pretreated solid.The increase in methane production was significant only after 15 days 200 of experimentation.Costa et al.(2014)found a high anaerobic biodegradability of the solid fraction of alkaline pretreated SCB (184C,47 min,0.80 M NaOH,3.2%(w/v)calculated).after the removal of lignin using NaOH solution,and water washing of the solid fraction.In this case the alkaline pretreated and subsequently 100 washed material generated 313.4 L CH4/kg substrate Thus,using only solid fractions from pretreatment C led to a significant enhancement of methane production,especially for WS,since the kinetic behavior of the inoculum was different for both substrates,probably due to the higher concentration of inhibitory compounds in pretreated sugarcane bagasse. 12 18 21 24 27 30 Lastly,the test on solid fractions from alkaline peroxide pre- Time(d) treatment (D)provided similar curves shapes for both substrates, SCB_D2 B_C2_model SCB_D2_mode typical for the degradation of two different substrates,and with a 300- lag period.In either case,starting with a methane production rate (b) similar to that from untreated raw material,there is a lag stage 250 from day 7 to day 20,reaching approximately 100-110 mL CH4/ g VS.and after this delay,the process of digestion restarts.This behavior could possibly be due to the presence of inhibitory com- 200- pounds and residual chemicals from pretreatment in samples of both substrates.The acclimation time for both substrates ends at 150- a very similar time to that found for the whole slurry of alkaline peroxide pretreated WS.After 30 days of the experiment,the 100- anaerobic biodegradability of WS_D2 was approximately 44%and the variable NP was 0.91,meaning a lower extent of reaction than untreated WS at this point of the experiment,whereas the biodegradability of sample SCB_D2 reached the value of 60%with E. a NP ratio of 1.16 at the same point in reaction time.This different effect on the tested substrates is opposite from that found in test 1. 2 15 18 21 24 77 30 3 when using the pretreatment liquid phase.The inhibitory com- Time(d) pounds'dilution effect in tests using the solid fraction allows for the microorganism's acclimation after a lag period,which was Fig.2.Experimental results and fitting curves of cumulative methane production from untreated materials and solid fraction after pretreatments(test 2).(A)Thermal not achieved in trials with SCB whole slurry.Once this acclimation autoclaving:(B)dilute acid autoclaving:(C)dilute alkali autoclaving:(D)alkaline period ends,the effect of alkaline peroxide pretreatment is higher peroxide pretreatment.(a)Wheat straw and (b)sugarcane bagasse. on SCB than on WS.lower biodegradability values compared to untreated substrates. However, it is necessary to analyze the results of tests with a solid fraction in order to compare the effect and efficiency of pretreatments on the biodegradability of both substrates. 3.2.2. Test 2: BMP of solid fraction from pretreatments Cumulative methane production curves from test 2 are presented in Fig. 2, where the results from WS (a) and SCB (b) were displayed together for comparison. Experimental results for the four tested pretreatments applied to each material are depicted together, as well as results from untreated substrates. In this test, solid fractions from the thermal pretreatment (A) of both substrates provided lower results than those of test 1 and of untreated substrates (Section 3.2.1). Thus, the anaerobic biodegradability of WS_A2 was only 40%, with a NP of 0.84. Some authors like Sambusiti et al. (2013) reported no difference in the methane production between the pretreated sample (100 C, 0.5 h) and untreated WS. Sample SCB_A2 provided similar results with an anaerobic biodegradability of 45% and NP of 0.9. Thus, using solid fractions from pretreatment A resulted in slightly lower yields of methane production for both substrates, perhaps due to the small solubilization of biodegradable VS in the pretreatment liquid. WS_A2 and SCB_A2 were seen to behave similarly to the untreated biomass during digestion assays. In contrast to test 1, where there was complete inhibition, when digesting the solid fraction from dilute acid autoclaving (B), some methanogenic activity, similar to that from the control occurred with both substrates. WS_B2 showed an anaerobic biodegradability of 17% with NP of 0.36, whereas sample SCB_B2 reached a biodegradability of 18% with NP of 0.35. This low methanogenic activity can be attributed to the dilution of inhibitory compounds remaining in the solid fraction, which were in lower concentration than in test 1, when using the pretreatment liquid, causing less inhibition. When solid fractions from dilute alkali pretreatment (C) were used, the highest methane yields of all trials were obtained from both substrates. The anaerobic biodegradability of WS_C2 increased up to 64% achieving a NP of 1.32. This is the best result obtained from all assays, especially considering that in less than 10 days a production of approximately 240 mL CH4/g VS was reached, representing 84% of total production in this assay. Other authors (Sambusiti et al., 2013) reported a higher methane production of 341 L CH4/kg VS, NP of 1.67 and 85% biodegradability working with the solid fraction of pretreated WS (10 g NaOH/100 g TS, 100 C, 0.5 h). However, Taherdanak and Zilouei (2014) reported methane production of 276 mL/g VS and NP of only 1.05 with pretreated WS (8% w/v NaOH, 100 C, 60 min). Alkali pretreatment also caused an increase in methane production from sample SCB_C2, which reached an anaerobic biodegradability of 68% and a NP of 1.30, but the degradation rate did not increase for this substrate. In the first period of the experiment, methane production from pretreated SCB was very similar to that from raw material or from thermal pretreated solid. The increase in methane production was significant only after 15 days of experimentation. Costa et al. (2014) found a high anaerobic biodegradability of the solid fraction of alkaline pretreated SCB (184 C, 47 min, 0.80 M NaOH, 3.2% (w/v) calculated), after the removal of lignin using NaOH solution, and water washing of the solid fraction. In this case the alkaline pretreated and subsequently washed material generated 313.4 L CH4/kg substrate. Thus, using only solid fractions from pretreatment C led to a significant enhancement of methane production, especially for WS, since the kinetic behavior of the inoculum was different for both substrates, probably due to the higher concentration of inhibitory compounds in pretreated sugarcane bagasse. Lastly, the test on solid fractions from alkaline peroxide pretreatment (D) provided similar curves shapes for both substrates, typical for the degradation of two different substrates, and with a lag period. In either case, starting with a methane production rate similar to that from untreated raw material, there is a lag stage from day 7 to day 20, reaching approximately 100–110 mL CH4/ g VS, and after this delay, the process of digestion restarts. This behavior could possibly be due to the presence of inhibitory compounds and residual chemicals from pretreatment in samples of both substrates. The acclimation time for both substrates ends at a very similar time to that found for the whole slurry of alkaline peroxide pretreated WS. After 30 days of the experiment, the anaerobic biodegradability of WS_D2 was approximately 44% and the variable NP was 0.91, meaning a lower extent of reaction than untreated WS at this point of the experiment, whereas the biodegradability of sample SCB_D2 reached the value of 60% with a NP ratio of 1.16 at the same point in reaction time. This different effect on the tested substrates is opposite from that found in test 1, when using the pretreatment liquid phase. The inhibitory compounds’ dilution effect in tests using the solid fraction allows for the microorganism’s acclimation after a lag period, which was not achieved in trials with SCB whole slurry. Once this acclimation period ends, the effect of alkaline peroxide pretreatment is higher on SCB than on WS. Fig. 2. Experimental results and fitting curves of cumulative methane production from untreated materials and solid fraction after pretreatments (test 2). (A) Thermal autoclaving; (B) dilute acid autoclaving; (C) dilute alkali autoclaving; (D) alkaline peroxide pretreatment. (a) Wheat straw and (b) sugarcane bagasse. S. Bolado-Rodríguez et al. / Bioresource Technology 201 (2016) 182–190 187����