正在加载图片...

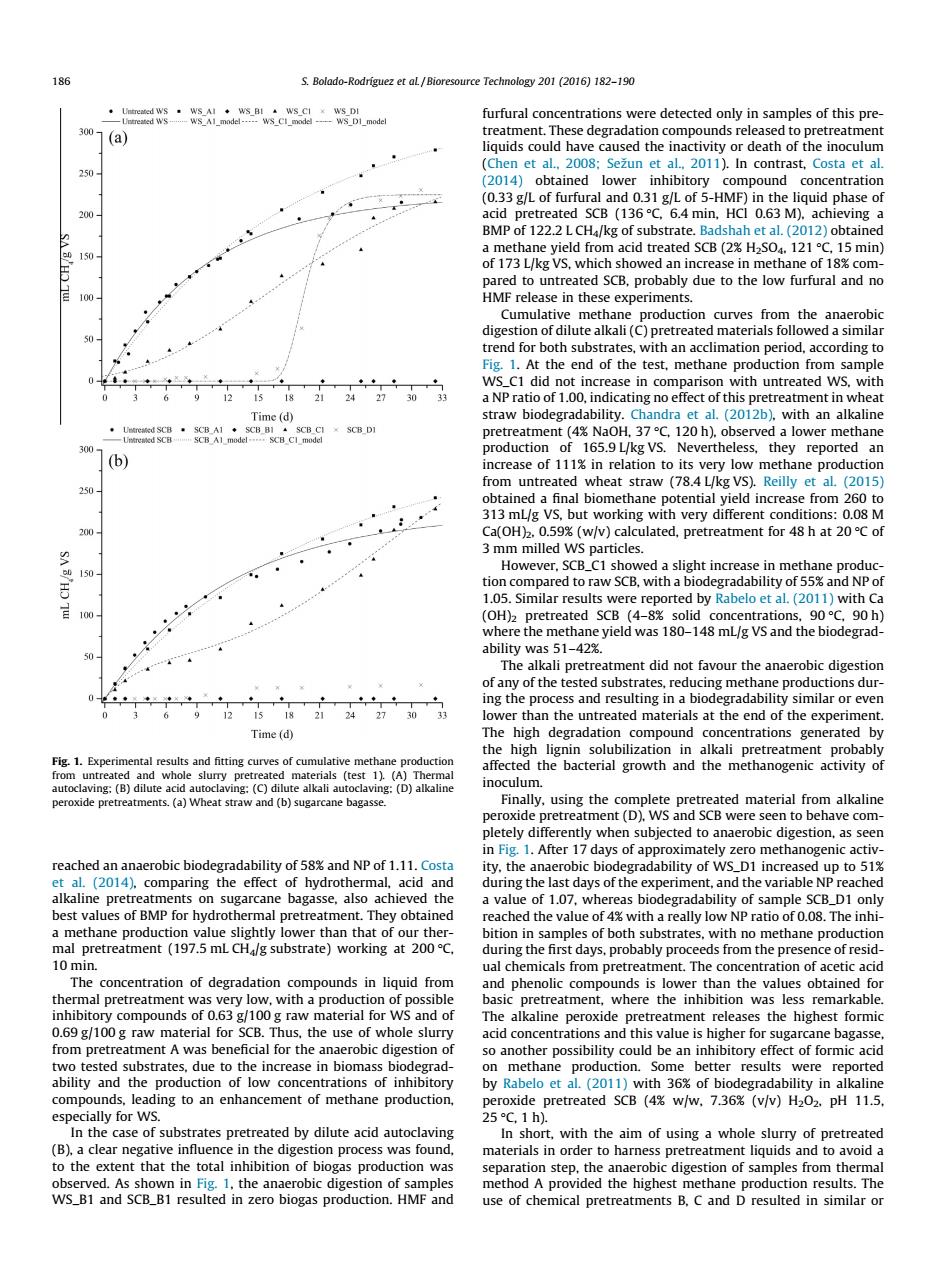

186 S.Bolado-Rodriguez et aL/Bioresource Technology 201 (2016)182-190 ·Untreated WS·WsAl+ws_Bl·Ws_C1×WsDI Uetreated WS-WS Al_model-----WS Cl model ----WS D1 model furfural concentrations were detected only in samples of this pre 300 (a) treatment.These degradation compounds released to pretreatment liquids could have caused the inactivity or death of the inoculum (Chen et al.,2008:Sezun et al.,2011).In contrast,Costa et al. 250 (2014)obtained lower inhibitory compound concentration (0.33 g/L of furfural and 0.31 g/L of 5-HMF)in the liquid phase of 200 acid pretreated SCB (136C,6.4 min,HCI 0.63 M).achieving a BMP of 122.2 L CH4/kg of substrate.Badshah et al.(2012)obtained a methane yield from acid treated SCB(2%H2SO4.121C,15 min) 150- of 173 L/kg VS,which showed an increase in methane of 18%com- pared to untreated SCB,probably due to the low furfural and no 100- HMF release in these experiments. Cumulative methane production curves from the anaerobic digestion of dilute alkali(C)pretreated materials followed a similar 50- trend for both substrates,with an acclimation period,according to Fig.1.At the end of the test,methane production from sample 0 WS_C1 did not increase in comparison with untreated WS,with 12 13 18 21 24 27 30 33 a NP ratio of 1.00,indicating no effect of this pretreatment in wheat Time (d) straw biodegradability.Chandra et al.(2012b),with an alkaline ·Untresed SCB·SCBA1·SCB8I·SCB CI SCB_D1 -Untreated SCBSCB_Al_model-SCB CI model pretreatment(4%NaOH,37C,120 h),observed a lower methane 300= production of 165.9 L/kg VS.Nevertheless,they reported an (b) increase of 111%in relation to its very low methane production 250 from untreated wheat straw(78.4 L/kg VS).Reilly et al.(2015) obtained a final biomethane potential yield increase from 260 to 313 mL/g VS,but working with very different conditions:0.08 M 200 Ca(OH)2.0.59%(w/v)calculated,pretreatment for 48 h at 20C of 3 mm milled WS particles. However,SCB_C1 showed a slight increase in methane produc- 150- tion compared to raw SCB,with a biodegradability of 55%and NP of 1.05.Similar results were reported by Rabelo et al.(2011)with Ca 100- (OH)2 pretreated SCB(4-8%solid concentrations.90C,90 h) where the methane yield was 180-148 mL/g VS and the biodegrad- 50- ability was 51-42%. The alkali pretreatment did not favour the anaerobic digestion of any of the tested substrates,reducing methane productions dur- 0- ◆ ing the process and resulting in a biodegradability similar or even 0 1215 18 21 24 27 lower than the untreated materials at the end of the experiment. Time(d) The high degradation compound concentrations generated by the high lignin solubilization in alkali pretreatment probably Fig.1.Experimental results and fitting curves of cumulative methane production affected the bacterial growth and the methanogenic activity of from untreated and whole slurry pretreated materials (test 1).(A)Thermal autoclaving:(B)dilute acid autoclaving:(C)dilute alkali autoclaving:(D)alkaline inoculum. peroxide pretreatments.(a)Wheat straw and (b)sugarcane bagasse. Finally,using the complete pretreated material from alkaline peroxide pretreatment(D).WS and SCB were seen to behave com- pletely differently when subjected to anaerobic digestion,as seen in Fig.1.After 17 days of approximately zero methanogenic activ- reached an anaerobic biodegradability of 58%and NP of 1.11.Costa ity,the anaerobic biodegradability of WS_D1 increased up to 51 et al.(2014).comparing the effect of hydrothermal,acid and during the last days of the experiment,and the variable NP reached alkaline pretreatments on sugarcane bagasse,also achieved the a value of 1.07,whereas biodegradability of sample SCB_D1 only best values of BMP for hydrothermal pretreatment.They obtained reached the value of 4%with a really low NP ratio of 0.08.The inhi- a methane production value slightly lower than that of our ther- bition in samples of both substrates,with no methane production mal pretreatment (197.5 mL CH4/g substrate)working at 200C. during the first days,probably proceeds from the presence of resid- 10 min. ual chemicals from pretreatment.The concentration of acetic acid The concentration of degradation compounds in liquid from and phenolic compounds is lower than the values obtained for thermal pretreatment was very low,with a production of possible basic pretreatment,where the inhibition was less remarkable. inhibitory compounds of 0.63 g/100g raw material for WS and of The alkaline peroxide pretreatment releases the highest formic 0.69 g/100 g raw material for SCB.Thus,the use of whole slurry acid concentrations and this value is higher for sugarcane bagasse, from pretreatment A was beneficial for the anaerobic digestion of so another possibility could be an inhibitory effect of formic acid two tested substrates,due to the increase in biomass biodegrad- on methane production.Some better results were reported ability and the production of low concentrations of inhibitory by Rabelo et al.(2011)with 36%of biodegradability in alkaline compounds,leading to an enhancement of methane production, peroxide pretreated SCB (4%w/w.7.36%(v/v)H202,pH 11.5, especially for WS. 25C,1h). In the case of substrates pretreated by dilute acid autoclaving In short,with the aim of using a whole slurry of pretreated (B),a clear negative influence in the digestion process was found materials in order to harness pretreatment liquids and to avoid a to the extent that the total inhibition of biogas production was separation step,the anaerobic digestion of samples from thermal observed.As shown in Fig.1,the anaerobic digestion of samples method A provided the highest methane production results.The WS_B1 and SCB_B1 resulted in zero biogas production.HMF and use of chemical pretreatments B,C and D resulted in similar orreached an anaerobic biodegradability of 58% and NP of 1.11. Costa et al. (2014), comparing the effect of hydrothermal, acid and alkaline pretreatments on sugarcane bagasse, also achieved the best values of BMP for hydrothermal pretreatment. They obtained a methane production value slightly lower than that of our thermal pretreatment (197.5 mL CH4/g substrate) working at 200 C, 10 min. The concentration of degradation compounds in liquid from thermal pretreatment was very low, with a production of possible inhibitory compounds of 0.63 g/100 g raw material for WS and of 0.69 g/100 g raw material for SCB. Thus, the use of whole slurry from pretreatment A was beneficial for the anaerobic digestion of two tested substrates, due to the increase in biomass biodegradability and the production of low concentrations of inhibitory compounds, leading to an enhancement of methane production, especially for WS. In the case of substrates pretreated by dilute acid autoclaving (B), a clear negative influence in the digestion process was found, to the extent that the total inhibition of biogas production was observed. As shown in Fig. 1, the anaerobic digestion of samples WS_B1 and SCB_B1 resulted in zero biogas production. HMF and furfural concentrations were detected only in samples of this pretreatment. These degradation compounds released to pretreatment liquids could have caused the inactivity or death of the inoculum (Chen et al., 2008; Sezˇun et al., 2011). In contrast, Costa et al. (2014) obtained lower inhibitory compound concentration (0.33 g/L of furfural and 0.31 g/L of 5-HMF) in the liquid phase of acid pretreated SCB (136 C, 6.4 min, HCl 0.63 M), achieving a BMP of 122.2 L CH4/kg of substrate. Badshah et al. (2012) obtained a methane yield from acid treated SCB (2% H2SO4, 121 C, 15 min) of 173 L/kg VS, which showed an increase in methane of 18% compared to untreated SCB, probably due to the low furfural and no HMF release in these experiments. Cumulative methane production curves from the anaerobic digestion of dilute alkali (C) pretreated materials followed a similar trend for both substrates, with an acclimation period, according to Fig. 1. At the end of the test, methane production from sample WS_C1 did not increase in comparison with untreated WS, with a NP ratio of 1.00, indicating no effect of this pretreatment in wheat straw biodegradability. Chandra et al. (2012b), with an alkaline pretreatment (4% NaOH, 37 C, 120 h), observed a lower methane production of 165.9 L/kg VS. Nevertheless, they reported an increase of 111% in relation to its very low methane production from untreated wheat straw (78.4 L/kg VS). Reilly et al. (2015) obtained a final biomethane potential yield increase from 260 to 313 mL/g VS, but working with very different conditions: 0.08 M Ca(OH)2, 0.59% (w/v) calculated, pretreatment for 48 h at 20 C of 3 mm milled WS particles. However, SCB_C1 showed a slight increase in methane production compared to raw SCB, with a biodegradability of 55% and NP of 1.05. Similar results were reported by Rabelo et al. (2011) with Ca (OH)2 pretreated SCB (4–8% solid concentrations, 90 C, 90 h) where the methane yield was 180–148 mL/g VS and the biodegradability was 51–42%. The alkali pretreatment did not favour the anaerobic digestion of any of the tested substrates, reducing methane productions during the process and resulting in a biodegradability similar or even lower than the untreated materials at the end of the experiment. The high degradation compound concentrations generated by the high lignin solubilization in alkali pretreatment probably affected the bacterial growth and the methanogenic activity of inoculum. Finally, using the complete pretreated material from alkaline peroxide pretreatment (D), WS and SCB were seen to behave completely differently when subjected to anaerobic digestion, as seen in Fig. 1. After 17 days of approximately zero methanogenic activity, the anaerobic biodegradability of WS_D1 increased up to 51% during the last days of the experiment, and the variable NP reached a value of 1.07, whereas biodegradability of sample SCB_D1 only reached the value of 4% with a really low NP ratio of 0.08. The inhibition in samples of both substrates, with no methane production during the first days, probably proceeds from the presence of residual chemicals from pretreatment. The concentration of acetic acid and phenolic compounds is lower than the values obtained for basic pretreatment, where the inhibition was less remarkable. The alkaline peroxide pretreatment releases the highest formic acid concentrations and this value is higher for sugarcane bagasse, so another possibility could be an inhibitory effect of formic acid on methane production. Some better results were reported by Rabelo et al. (2011) with 36% of biodegradability in alkaline peroxide pretreated SCB (4% w/w, 7.36% (v/v) H2O2, pH 11.5, 25 C, 1 h). In short, with the aim of using a whole slurry of pretreated materials in order to harness pretreatment liquids and to avoid a separation step, the anaerobic digestion of samples from thermal method A provided the highest methane production results. The use of chemical pretreatments B, C and D resulted in similar or Fig. 1. Experimental results and fitting curves of cumulative methane production from untreated and whole slurry pretreated materials (test 1). (A) Thermal autoclaving; (B) dilute acid autoclaving; (C) dilute alkali autoclaving; (D) alkaline peroxide pretreatments. (a) Wheat straw and (b) sugarcane bagasse. 186 S. Bolado-Rodríguez et al. / Bioresource Technology 201 (2016) 182–190�������