正在加载图片...

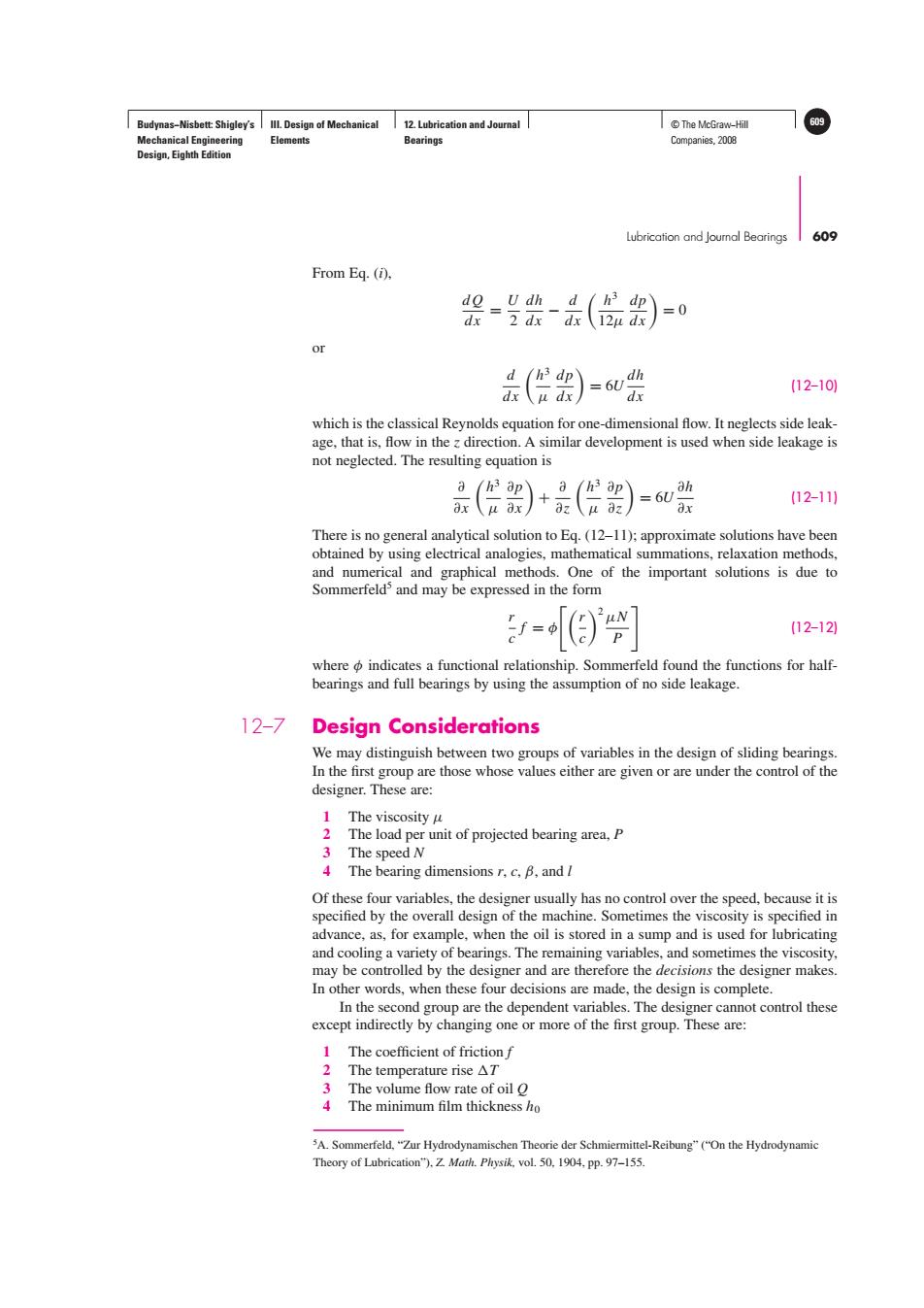

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 12.Lubrication and Journal T©The McGraw--Hill 609 Mechanical Engineering Elements Bearings Companies,2008 Design,Eighth Edition Lubrication and Joumnal Bearings 609 From Eq.(i), -号-(你)=0 dx or d (hs dp =6 (12-10) dxu dx which is the classical Reynolds equation for one-dimensional flow.It neglects side leak- age,that is,flow in the z direction.A similar development is used when side leakage is not neglected.The resulting equation is a(h3 ap a(h3 ap 6U ih (12-11) ax u ax azu az ax There is no general analytical solution to Eq.(12-11):approximate solutions have been obtained by using electrical analogies,mathematical summations,relaxation methods, and numerical and graphical methods.One of the important solutions is due to Sommerfelds and may be expressed in the form (12-12 where o indicates a functional relationship.Sommerfeld found the functions for half- bearings and full bearings by using the assumption of no side leakage. 12-7 Design Considerations We may distinguish between two groups of variables in the design of sliding bearings. In the first group are those whose values either are given or are under the control of the designer.These are: 1 The viscosity u 2 The load per unit of projected bearing area,P 3 The speed N 4 The bearing dimensions r,c,B,and I Of these four variables,the designer usually has no control over the speed,because it is specified by the overall design of the machine.Sometimes the viscosity is specified in advance,as,for example,when the oil is stored in a sump and is used for lubricating and cooling a variety of bearings.The remaining variables,and sometimes the viscosity, may be controlled by the designer and are therefore the decisions the designer makes. In other words,when these four decisions are made,the design is complete. In the second group are the dependent variables.The designer cannot control these except indirectly by changing one or more of the first group.These are: 1 The coefficient of friction f 2 The temperature rise AT 3 The volume flow rate of oil O 4 The minimum film thickness ho 5A.Sommerfeld,"Zur Hydrodynamischen Theorie der Schmiermittel-Reibung"("On the Hydrodynamic Theory of Lubrication").Z Math.Physik,vol.50.1904.pp.97-155.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 12. Lubrication and Journal Bearings © The McGraw−Hill 609 Companies, 2008 Lubrication and Journal Bearings 609 From Eq. (i), d Q dx = U 2 dh dx − d dx h3 12μ dp dx = 0 or d dx h3 μ dp dx = 6U dh dx (12–10) which is the classical Reynolds equation for one-dimensional flow. It neglects side leakage, that is, flow in the z direction. A similar development is used when side leakage is not neglected. The resulting equation is ∂ ∂x h3 μ ∂p ∂x + ∂ ∂z h3 μ ∂p ∂z = 6U ∂h ∂x (12–11) There is no general analytical solution to Eq. (12–11); approximate solutions have been obtained by using electrical analogies, mathematical summations, relaxation methods, and numerical and graphical methods. One of the important solutions is due to Sommerfeld5 and may be expressed in the form r c f = φ r c 2 μN P (12–12) where φ indicates a functional relationship. Sommerfeld found the functions for halfbearings and full bearings by using the assumption of no side leakage. 12–7 Design Considerations We may distinguish between two groups of variables in the design of sliding bearings. In the first group are those whose values either are given or are under the control of the designer. These are: 1 The viscosity μ 2 The load per unit of projected bearing area, P 3 The speed N 4 The bearing dimensions r, c, β, and l Of these four variables, the designer usually has no control over the speed, because it is specified by the overall design of the machine. Sometimes the viscosity is specified in advance, as, for example, when the oil is stored in a sump and is used for lubricating and cooling a variety of bearings. The remaining variables, and sometimes the viscosity, may be controlled by the designer and are therefore the decisions the designer makes. In other words, when these four decisions are made, the design is complete. In the second group are the dependent variables. The designer cannot control these except indirectly by changing one or more of the first group. These are: 1 The coefficient of friction f 2 The temperature rise T 3 The volume flow rate of oil Q 4 The minimum film thickness h0 5 A. Sommerfeld, “Zur Hydrodynamischen Theorie der Schmiermittel-Reibung” (“On the Hydrodynamic Theory of Lubrication”), Z. Math. Physik, vol. 50, 1904, pp. 97–155.����������