正在加载图片...

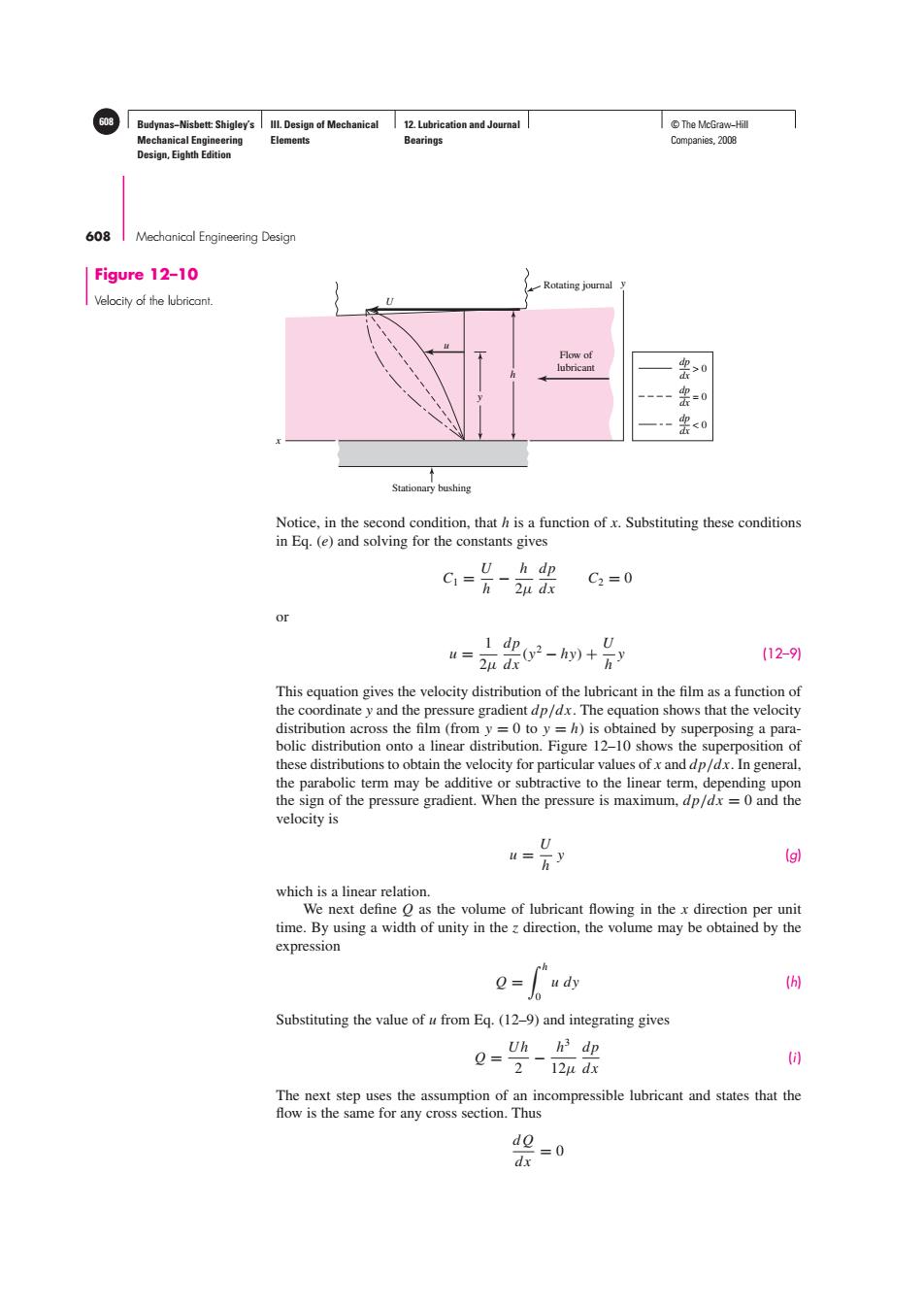

608 Budynas-Nisbett:Shigley's Ill.Design of Mechanical 12.Lubrication and Journal T©The McGraw-Hil Mechanical Engineering Elements Bearings Companies,2008 Design,Eighth Edition 608 Mechanical Engineering Design Figure 12-10 Rotating journal y Velocity of the lubricant. Flow of lubricant 0 0 黑<0 Stationary bushing Notice,in the second condition,that h is a function ofx.Substituting these conditions in Eq.(e)and solving for the constants gives U h dp C1=i-2μdx C2=0 or 1 dp U 4= 2u dx 202-h+) (12-91 This equation gives the velocity distribution of the lubricant in the film as a function of the coordinate y and the pressure gradient dp/dx.The equation shows that the velocity distribution across the film(from y =0 to y =h)is obtained by superposing a para- bolic distribution onto a linear distribution.Figure 12-10 shows the superposition of these distributions to obtain the velocity for particular values of x and dp/dx.In general, the parabolic term may be additive or subtractive to the linear term,depending upon the sign of the pressure gradient.When the pressure is maximum,dp/dx=0 and the velocity is U =y (g) which is a linear relation. We next define O as the volume of lubricant flowing in the x direction per unit time.By using a width of unity in the z direction,the volume may be obtained by the expression Q= u dy Substituting the value of u from Eq.(12-9)and integrating gives Uh h3 dp Q= 2-12μdx The next step uses the assumption of an incompressible lubricant and states that the flow is the same for any cross section.Thus do =0 dxBudynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 12. Lubrication and Journal Bearings 608 © The McGraw−Hill Companies, 2008 608 Mechanical Engineering Design Notice, in the second condition, that h is a function of x. Substituting these conditions in Eq. (e) and solving for the constants gives C1 = U h − h 2μ dp dx C2 = 0 or u = 1 2μ dp dx (y2 − hy) + U h y (12–9) This equation gives the velocity distribution of the lubricant in the film as a function of the coordinate y and the pressure gradient dp/dx. The equation shows that the velocity distribution across the film (from y = 0 to y = h) is obtained by superposing a parabolic distribution onto a linear distribution. Figure 12–10 shows the superposition of these distributions to obtain the velocity for particular values of x and dp/dx. In general, the parabolic term may be additive or subtractive to the linear term, depending upon the sign of the pressure gradient. When the pressure is maximum, dp/dx = 0 and the velocity is u = U h y (g) which is a linear relation. We next define Q as the volume of lubricant flowing in the x direction per unit time. By using a width of unity in the z direction, the volume may be obtained by the expression Q = h 0 u dy (h) Substituting the value of u from Eq. (12–9) and integrating gives Q = Uh 2 − h3 12μ dp dx (i) The next step uses the assumption of an incompressible lubricant and states that the flow is the same for any cross section. Thus d Q dx = 0 h y U u x y Flow of lubricant Stationary bushing Rotating journal dp dx > 0 dp dx = 0 dp dx < 0 Figure 12–10 Velocity of the lubricant