正在加载图片...

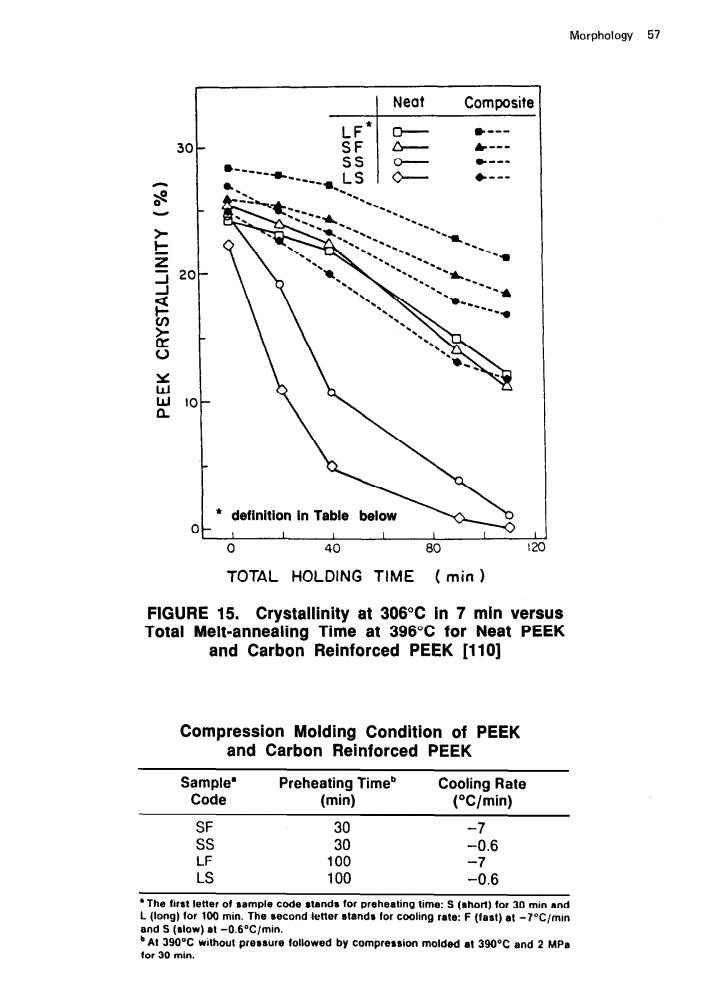

Morphology 57 Neat Composite L 30 ● ◆- 20 )33d 10 definition in Table below 0 40 80 120 TOTAL HOLDING TIME min FIGURE 15.Crystallinity at 306C in 7 min versus Total Melt-annealing Time at 396C for Neat PEEK and Carbon Reinforced PEEK [110] Compression Molding Condition of PEEK and Carbon Reinforced PEEK Sample" Preheating Time° Cooling Rate Code (min) (°c/min) 30 -7 S 30 -0.6 LF 100 -7 LS 100 -0.6 .The first letter of sample code stands for preheating time:S(short)for 30 min and L (long)for 100 min.The second letter stands for cooling rate:F (fast)at-7C/min tolod by comp Cand2P for 30 minMorphology 57 l- )- ) Neat Composite 0 40 80 I2 TOTAL HOLDING TIME ( min ) FIGURE 15. Crystallinity at 306°C in 7 min versus Total Melt-annealing Time at 396% for Neat PEEK and Carbon Reinforced PEEK [llO] Compression Molding Condition of PEEK and Carbon Reinforced PEEK Sample’ Preheating Timeb Cooling Rate Code (min) (OC/min) SF 30 -7 ss 30 -0.6 LF 100 -7 LS 100 -0.6 ‘The lirst letter 01 sample coda stands tar preheating time: S (short) Ior 30 min and L (long) lor 100 min. The second letter standr lor cooling rate: F (last) at -7“Cjmln and S (slow) at -0.6°C/min. b At 390% without pressure followed by compression molded at 390°C and 2 MPa lor 30 min