正在加载图片...

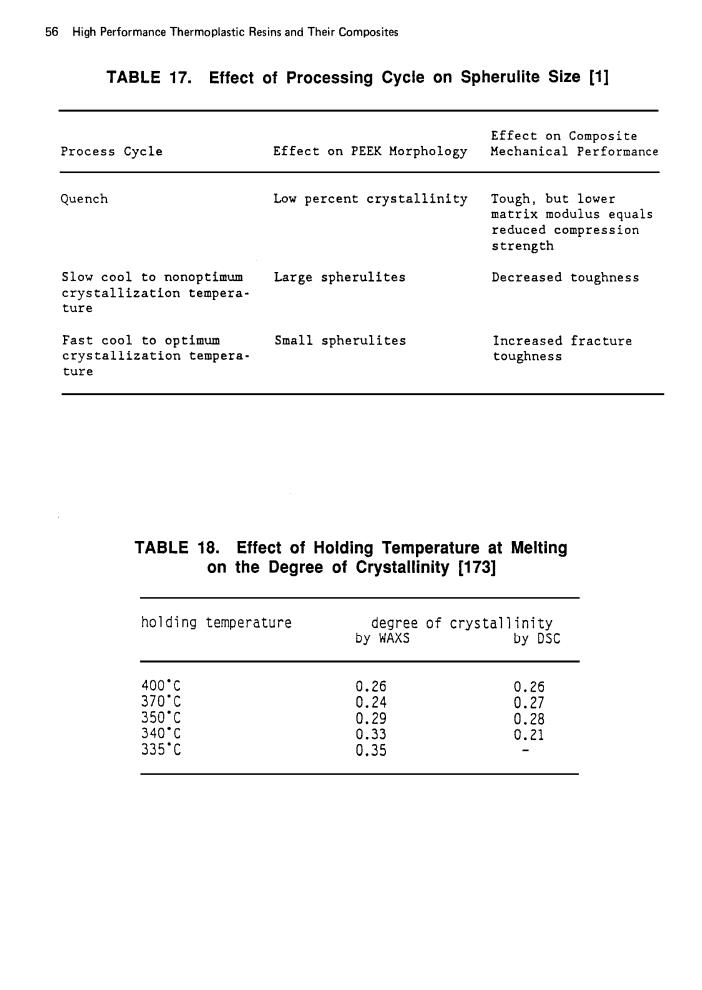

56 High Performance Thermoplastic Resins and Their Composites TABLE 17.Effect of Processing Cycle on Spherulite Size [1] Effect on Composite Process Cycle Effect on PEEK Morphology Mechanical Performance Quench Low percent crystallinity Tough,but lower matrix modulus equals reduced compression strength Slow cool to nonoptimum Large spherulites Decreased toughness crystallization tempera- ture Fast cool to optimum Small spherulites Increased fracture crystallization tempera- toughness ture TABLE 18.Effect of Holding Temperature at Melting on the Degree of Crystallinity [173] holding temperature degree of crystallinity by WAXS by DSC 400*c 0.26 0.26 370'C 0.24 0.27 350*C 0.29 0.28 340"C 0.33 0.21 335C 0.3556 High Performance Thermoplastic Resins and Their Composites TABLE 17. Effect of Processing Cycle on Spherulite Size [l] Process Cycle Effect on Composite Effect on PEEK Morphology Mechanical Performance Quench Low percent crystallinity Tough, but lower matrix modulus equals reduced compression strength Slow cool to nonoptimum Large spherulites Decreased toughness crystallization temperature Fast cool to optimum Small spherulites Increased fracture crystallization tempera- toughness ture TABLE 18. Effect of Holding Temperature at Melting on the Degree of Crystallinity [173] holding temperature degree of crystallinity by WAXS by DSC 400-c 0.26 0.26 370-c 0.24 0.27 350-c 0.29 0.28 34O'C 0.33 0.21 335-c 0.35