正在加载图片...

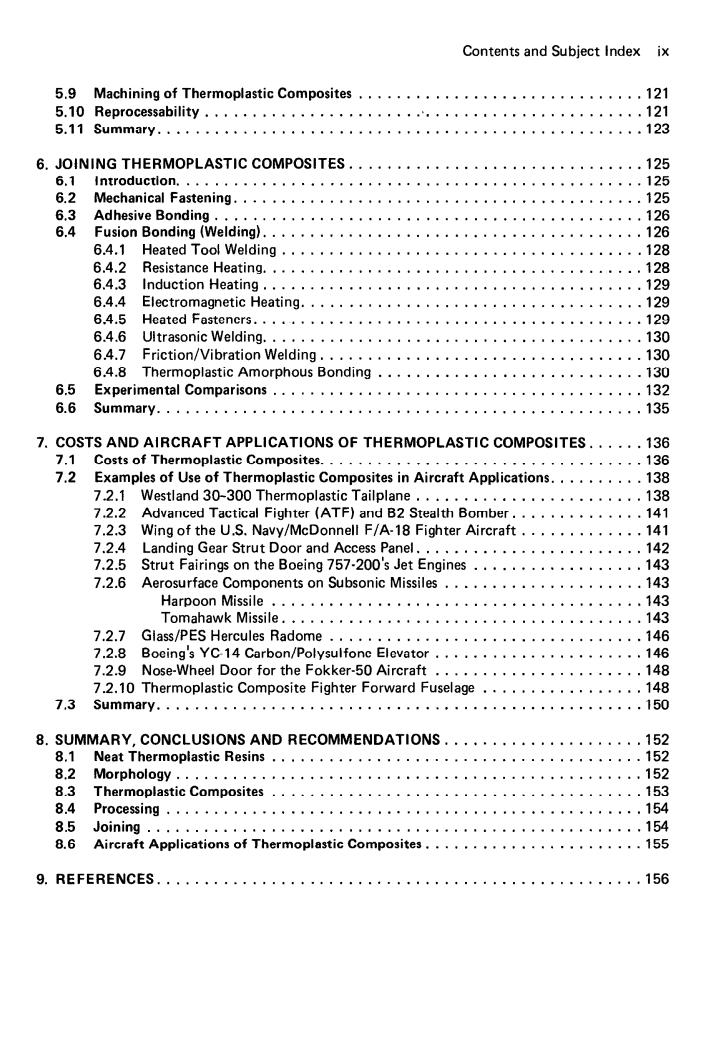

Contents and Subject Index ix 5.9 Machining of Thermoplastic Composites ......... ··········:,121 5.10 Reprocessability,,·,·,···,············.·· ···········.121 5.11 Summary..·。···················· 6.J04 NING THERMOPLASTIC C0MPOS1TES,..·,·,,........,....,..,...,..125 6.1 introduction.…………………125 6.2 Mechanical Fastening...........................................125 6.3 Adhesive Bonding.............................................126 6.4 Fusion Bonding(Welding)..···,·,········ 6.4.1 Heated Tool Welding............... 6.4.2 Resistance Heating........................................128 6.4.3 Induction Heating ....... 6.4.4 Electromagnetic Heating........ ···....129 64.5 Heated Fastencrs...,,.,·...:.·.,...···...···...,.··.129 6.4.6 Ultrasonic Welding............... .··.,.130 6.4.7 Friction/Vibration Welding........ .....130 6.4.8 Thermoplastic Amorphous Bonding..... .·....130 6.5 Experimental Comparisons .............. ··...132 6.6 Summary..…135 7.COSTS AND AIRCRAFT APPLICATIONS OF THERMOPLASTIC COMPOSITES......136 7.1 Costs of Thermoplastic Composites..................................136 7.2 Examples of Use of Thermoplastic Composites in Aircraft Applications..........138 7.2.1 Westland 30-300 Thermoplastic Tailplane........................138 7.2.2 Advanced Tactical Fighter (ATF)and B2 Stealth Bomber..............141 7.2.3 Wing of the U.S.Navy/McDonnell F/A-18 Fighter Aircraft.............141 7.2.4 Landing Gear Strut Door and Access Panel........................142 7.2.5 Strut Fairings on the Boeing 757-200's Jet Engines..................143 7.2.6 Aerosurface Components on Subsonic Missiles.....................143 Harpoon Missile,....,,,,,.,.,,.,,.........·.......143 Tomahawk Missile.…14 7.2.7 Glass/PES Hercules Radome ............. 7.2.8 Boeing's YC14 Carbon/Polysulfonc Elevator .....................146 7.2.9 Nose-Wheel Door for the Fokker-50 Aircraft......................148 7.2.10 Thermoplastic Composite Fighter Forward Fuselage 7.3 8.SUMMARY,CONCLUSIONS AND RECOMMENDATIONS.·,.·...·....·..152 8.1 Neat Thermoplastic Resins ................... .....152 8.2 Morphology.·············· .·.152 8.3 Thermoplastic Composites ... ,..153 8.4 Processing.·,··········· ...154 8.5 Joining..,··.· ...154 8.6 Aircraft Applications of Thermoplastic Composites............ ...155 9.REFERENCES,.,,··.··. ..,156Contents and Subject Index ix 5.9 Machining of Thermoplastic Composites .............................. 121 5.10 Reprocessability ............................................... 121 5.11 Summary .................................................. .I23 6. JOINING THERMOPLASTIC COMPOSITES .............................. .I25 6.1 Introduction. ............................................... .I25 6.2 Mechanical Fastening. .......................................... 125 6.3 Adhesive Bonding. ........................................... .I26 6.4 Fusion Bonding (Welding). ....................................... 126 6.4.1 Heated Tool Welding ..................................... .I28 6.4.2 Resistance Heating. ....................................... 128 6.4.3 Induction Heating ........................................ 129 6.4.4 Electromagnetic Heating. ................................... 129 6.4.5 Heated Fasteners. ........................................ 129 6.4.6 Ultrasonic Welding. ....................................... 130 6.4.7 Friction/Vibration Welding. ................................. 130 6.4.8 Thermoplastic Amorphous Bonding ........................... .I30 6.5 Experimental Comparisons ....................................... 132 6.6 Summary. .................................................. 135 7. COSTS AND AIRCRAFT APPLICATIONS OF THERMOPLASTIC COMPOSITES. ..... 136 7.1 Costs of Thermoplastic Composites. ................................. 136 7.2 Examples of Use of Thermoplastic Composites in Aircraft Applications. ......... 138 7.2.1 Westland 30-300 Thermoplastic Tailplane ........................ 138 7.2.2 Advanced Tactical Fighter (ATF) and B2 Stealth Bomber. ............. 141 7.2.3 Wing of the U.S. Navy/McDonnell F/A-18 Fighter Aircraft ............. 141 7.2.4 Landing Gear Strut Door and Access Panel. ....................... 142 7.2.5 Strut Fairings on the Boeing 757-200’s Jet Engines .................. 143 7.2.6 Aerosurface Components on Subsonic Missiles ..................... 143 Harpoon Missile ...................................... .I43 Tomahawk Missile. .................................... .I43 7.2.7 Glass/PES Hercules Radome ................................ .I46 7.2.8 Boeing’s YC-14 Carbon/Polysulfone Elevator ...................... 146 7.2.9 Nose-Wheel Door for the Fokker-50 Aircraft ...................... 148 7.2.10 Thermoplastic Composite Fighter Forward Fuselage ................. 148 7.3 Summary...................................................15 0 8. SUMMARY, CONCLUSIONS AND RECOMMENDATIONS. ................... .I52 8.1 Neat Thermoplastic Resins ....................................... 152 8.2 Morphology ................................................ .I52 8.3 Thermoplastic Composites ...................................... .I53 8.4 Processing ................................................. .I54 8.5 Joining....................................................15 4 8.6 Aircraft Applications of Thermoplastic Composites. ...................... 155 9.REFERENCES...................................................156