Contents and Subject Index 1.NTR0 DUCTIC0N....··.,··.··,.1 2.NEAT THERMOPLASTIC RESINS PROPERTIES.···,·.,.,,.,.,,,,,,..,,,,,..3 2.1 Introduction....................................................3 2.2 Properties of Neat Thermoplastic Resins.................................4 2.2.1 Chemical Structure and Some Physical Properties ......................4 2.2.2 Thermal Properties........................................13 2.2.3 Mechanical Properties..........................,·,,,,.21 2.2.4 Toughness..········· 2.2.5 Non-Linear and Time-Dependent Behavior..........................28 2.2.6 Chemical Resistance.........................................28 2.2.7 Water and Moisture Resistance....... ·····.32 2.3 Characteristics of Some Thermoplastic Polymer Families............ ··.33 2.3.1 Polyketones.········· ····.33 Polyetheretherketone (PEEK)................................33 Polyetherketoneketone (PEKK)...............................36 Polyetherketoneetherketoneketone (PEKEKK).....................36 Polyetherketone(PEK).................,....,,,.,,,,.,,,.,36 23.2 Polyarylene Sulfides.,.·..,....,..·....,...................36 Polyphenylene Sulfide (PPS)......................... ·······.36 Polyarylene Sulfide (PAS-2)......................... ···,37 Polyphenylene Sulfide Sulfone (PPSS)................... ····.39 233 Polyamides..,.,...·.。.················ ·····.39 Polyamide小2.,,.,,··,·,·················· ······.39 Polyamideimide (PAl)Torlon........ ·····.39 23.4 Polyimides...,..,·,,,,,,,··· ····.40 Polyimide K-Polymer................. ···…..40 Polyimide N-Polymer.,,..,,,·,,.· ····.41 Polyimide Eymyd..,·,········· Polyketoimide Larc-TPI..,,·,,··· ···.44 Polyetherimide PEI,,,,,,···· 2.3.5 Polysulfones......·,..····.· ···.45 2.3.6 Liquid Crystalline Polymers...... ···..46 2.3.7 Polybenzimidazoles (PBI)... ···.49 2.3.8 Polyphenylquinoxalines(Ppal.··· ··.50 2.4 Summary.,,,··,··,··········· 。。 ,,..50 vii

Contents and Subject Index 1. INTRODUCTION ................................................. ..l 2. NEAT THERMOPLASTIC RESINS PROPERTIES ............................ .3 2.1 2.2 2.3 2.4 Introduction. .................................................. .3 Properties of Neat Thermoplastic Resins ................................ .4 2.2.1 Chemical Structure and Some Physical Properties ..................... .4 2.2.2 Thermal Properties ........................................ .13 2.2.3 Mechanical Properties. ...................................... .21 2.2.4 Toughness. ............................................. .21 2.2.5 Non-Linear and Time-Dependent Behavior. ........................ .28 2.2.6 Chemical Resistance. ....................................... .28 2.2.7 Water and Moisture Resistance. ................................ .32 Characteristics of Some Thermoplastic Polymer Families .................... .33 2.3.1 Polyketones ............................................. .33 Polyetheretherketone (PEEK) ............................... .33 Polyetherketoneketone (PEKK) .............................. .36 Polyetherketoneetherketoneketone (PEKEKK). ................... .36 Polyetherketone (PEK). ................................... .36 2.3.2 Polyarylene Sulfides. ....................................... .36 Polyphenylene Sulfide (PPS) ................................ .36 Polyarylene Sulfide (PAS-2) ................................ .37 Polyphenylene Sulfide Sulfone (PPSS). ......................... .39 2.3.3 Polyamides. ............................................. .39 Polyamide J-2. ......................................... .39 Polyamideimide (PAI) Torlon ............................... .39 2.3.4 Polyimides. ............................................. .40 Polyimide K-Polymer. .................................... .40 Polyimide N-Polymer. .................................... .41 Polyimide Eymyd ....................................... .44 Polyketoimide Larc-TPI ................................... .44 Polyetherimide PEI ...................................... .44 2.3.5 Polysulfones. ............................................ .45 2.3.6 Liquid Crystalline Polymers. .................................. .46 2.3.7 Polybenzimidazoles (PBI) .................................... .49 2.3.8 Polyphenylquinoxalines (PPQ). ................................ .50 Summary.....................................................5 0 vii

viii Contents and Subject Index 3.M0RPH0L0GY.,··,····,,,,.53 3.1 Introduction.··.·,.·..,...53 3.2 Factors Influencing Morphology of Semi-Crystalline Thermoplastics..............53 3.2.1 Processing Conditions...,.............,,.................,..53 3.2.2 Foreign Surfaces..,...........,.......,,,,,,.,..,.......58 3.3 Morphology-Property Relationships of Semi-Crystalline Thermoplastics..·········.60 3.4 Summary.················ 4.PERFORMANCE OF THERMOPLASTIC BASED COMPOSITES·,,,·,,,..·.,··.,.67 4.1 Introduction...... .. 4.2 Room Temperature Mechanical Properties..··..··.·············· ···.67 4.3 Elevated Temperature Mechanical Properties··,············· ···.75 4.4 Damage Resistance and Tolerance.,..,..,.,..·.·.,.,·.··.·· ··..78 4.4.1 Interlaminar Fracture Toughness ...................... ·。.78 4.4.2 Delamination Behavior.,,.,:,,,·,,,,·,············· ·。.81 4.4.3 Damage Tolerance.,,·。·············,········'''' ····.83 4.5 Fatigue Resistance.························ ····.86 4.6 Time-Dependent Behavior........ 4.7 Resistance to Thermal Cycling and lonizing Radiation.......................91 4.7.1 Thermal Cycling................,,.,.....91 4.7.2 Electron Radiation...........,...,..,..........91 4.8Summ8y..........................................92 5.PROCESSING OF ADVANCED THERMOPLASTIC COMPOSITES.···············.96 5.1 Introduction.…9G 5.2 Advantages/Disadvantages................ 5.3 Treatment of Fibers......,,,.·,...······ 5.4 Combination of Fibers with Matrix..,..,.······· ····.98 5.4.1 Hot Melt Coating.,.·.··············· 5.4.2 Solution Processing ..... 5.4.3 ln-Situ Polymerization of Monomers or Prepolymers.,··...···,. .,.101 5.4.4 Film Stacking......·.·. ,..101 5.4.5 Powder Coating.,············ ··.102 5.4.6 Fiber Hybridization,,.············ ,·.102 5,5Ly-Up,。,.。,,,.。.。,.,,,,,。.,,,,,,.。。.,。. ...108 5.6 Processing Techniques for Thermoplastic Composites.,··,·,,····, .,.108 5.6.1 Melting.,.,······ ..108 5.6.2 Consolidation,,··········· ,·.108 5.6.3 Solidification.············· ·.110 5.6.4 Residual Stresses,··············· ..110 5.6.5 Models.. .111 5.7 Processing of Flat Thermoplastic Laminates..... ..111 5.7.1 Compression Molding,,,,,,,.,··,. ,.112 5.7.2 Autoclave Technology ........ ,112 5.7.3 Automated Lamination and Consolidation.... .112 5.8 Forming Techniques.,.,,.····..··.······ ..113 5.8.1 Matched Die Press Forming...... .114 5.8.2 Rubber Pad Press Forming ... 114 5.8.3 Diaphragm Forming....... ..117 5.8.4 Hydroforming.,,,····· 117 5.8.5 Autoclave/Vacuum Forming .... ···.117 58.6 Filament Winding.·,,.,.·..,, ....120 5.8.7 Pultrusion.·.············· ...120 5.8.8 Roll Forming..··,········· ·.,121

viii Contents and Subject Index 3.MORPHOLOGY...................................................53 3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . ,. . . . . . . . . . . . . . . . . . . . . . .53 3.2 Factors Influencing Morphology of Semi-Crystalline Thermoplastics. . . . . . . . . . . . . .53 3.2.1 Processing Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 3.2.2 Foreign Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58 3.3 Morphology-Property Relationships of Semi-Crystalline Thermoplastics. . . . . . . . . . . .60 3.4 Summary.....................................................64 4. PERFORMANCE OF THERMOPLASTIC BASED COMPOSITES . . . . . . . . . . . . . . . . . .67 4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67 4.2 Room Temperature Mechanical Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67 4.3 Elevated Temperature Mechanical Properties . . . . . . . . . . . . . . . . . . . . . . , . . . , . .75 4.4 Damage Resistance and Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78 4.4.1 lnterlaminar Fracture Toughness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _ .78 4.4.2 Delamination Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81 4.4.3 Damage Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83 4.5 Fatigue Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86 4.6 Time-Dependent Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89 4.7 Resistance to Thermal Cycling and Ionizing Radiation . . . . . . . . . . . . . . . . . . . . . . .91 4.7.1 Thermal Cycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91 4.7.2 Electron Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91 4.8 Summary.....................................................92 5. PROCESSING OF ADVANCED THERMOPLASTIC COMPOSITES. . . . . . . . . . . . . . . . .96 5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96 5.2 Advantages/Disadvantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96 5.3 Treatment of Fibers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97 5.4 Combination of Fibers with Matrix. . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . .98 5.4.1 Hot Melt Coating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99 5.4.2 Solution Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99 5.4.3 In-Situ Polymerization of Monomers or Prepolymers . . . . . . . . . . . . . . . . . . 101 5.4.4 Film Stacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I01 5.4.5 Powder Coating.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102 5.4.6 Fiber Hybridization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I02 5.5 Lay_Up.....................................................lO8 5.6 Processing Techniques for Thermoplastic Composites. . . . . . . . . . . . . . . . . . . . . . . 108 5.6.1 Melting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I08 5.6.2 Consolidation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108 5.6.3 Solidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 5.6.4 Residual Stresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 5.6.5 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..lll 5.7 Processing of Flat Thermoplastic Laminates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 5.7.1 Compression Molding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 5.7.2 Autoclave Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 5.7.3 Automated Lamination and Consolidation. . . . . . . . . . . . . . . . . . . . . . . . . 112 5.8 Forming Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113 5.8.1 Matched Die Press Forming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 5.8.2 Rubber Pad Press Forming . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 5.8.3 Diaphragm Forming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I17 5.8.4 Hydroforming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I17 5.8.5 Autoclave/Vacuum Forming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 5.8.6 Filament Winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I20 5.8.7 Pultrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I20 5.8.8 Roll Forming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I21

Contents and Subject Index ix 5.9 Machining of Thermoplastic Composites ......... ··········:,121 5.10 Reprocessability,,·,·,···,············.·· ···········.121 5.11 Summary..·。···················· 6.J04 NING THERMOPLASTIC C0MPOS1TES,..·,·,,........,....,..,...,..125 6.1 introduction.…………………125 6.2 Mechanical Fastening...........................................125 6.3 Adhesive Bonding.............................................126 6.4 Fusion Bonding(Welding)..···,·,········ 6.4.1 Heated Tool Welding............... 6.4.2 Resistance Heating........................................128 6.4.3 Induction Heating ....... 6.4.4 Electromagnetic Heating........ ···....129 64.5 Heated Fastencrs...,,.,·...:.·.,...···...···...,.··.129 6.4.6 Ultrasonic Welding............... .··.,.130 6.4.7 Friction/Vibration Welding........ .....130 6.4.8 Thermoplastic Amorphous Bonding..... .·....130 6.5 Experimental Comparisons .............. ··...132 6.6 Summary..…135 7.COSTS AND AIRCRAFT APPLICATIONS OF THERMOPLASTIC COMPOSITES......136 7.1 Costs of Thermoplastic Composites..................................136 7.2 Examples of Use of Thermoplastic Composites in Aircraft Applications..........138 7.2.1 Westland 30-300 Thermoplastic Tailplane........................138 7.2.2 Advanced Tactical Fighter (ATF)and B2 Stealth Bomber..............141 7.2.3 Wing of the U.S.Navy/McDonnell F/A-18 Fighter Aircraft.............141 7.2.4 Landing Gear Strut Door and Access Panel........................142 7.2.5 Strut Fairings on the Boeing 757-200's Jet Engines..................143 7.2.6 Aerosurface Components on Subsonic Missiles.....................143 Harpoon Missile,....,,,,,.,.,,.,,.........·.......143 Tomahawk Missile.…14 7.2.7 Glass/PES Hercules Radome ............. 7.2.8 Boeing's YC14 Carbon/Polysulfonc Elevator .....................146 7.2.9 Nose-Wheel Door for the Fokker-50 Aircraft......................148 7.2.10 Thermoplastic Composite Fighter Forward Fuselage 7.3 8.SUMMARY,CONCLUSIONS AND RECOMMENDATIONS.·,.·...·....·..152 8.1 Neat Thermoplastic Resins ................... .....152 8.2 Morphology.·············· .·.152 8.3 Thermoplastic Composites ... ,..153 8.4 Processing.·,··········· ...154 8.5 Joining..,··.· ...154 8.6 Aircraft Applications of Thermoplastic Composites............ ...155 9.REFERENCES,.,,··.··. ..,156

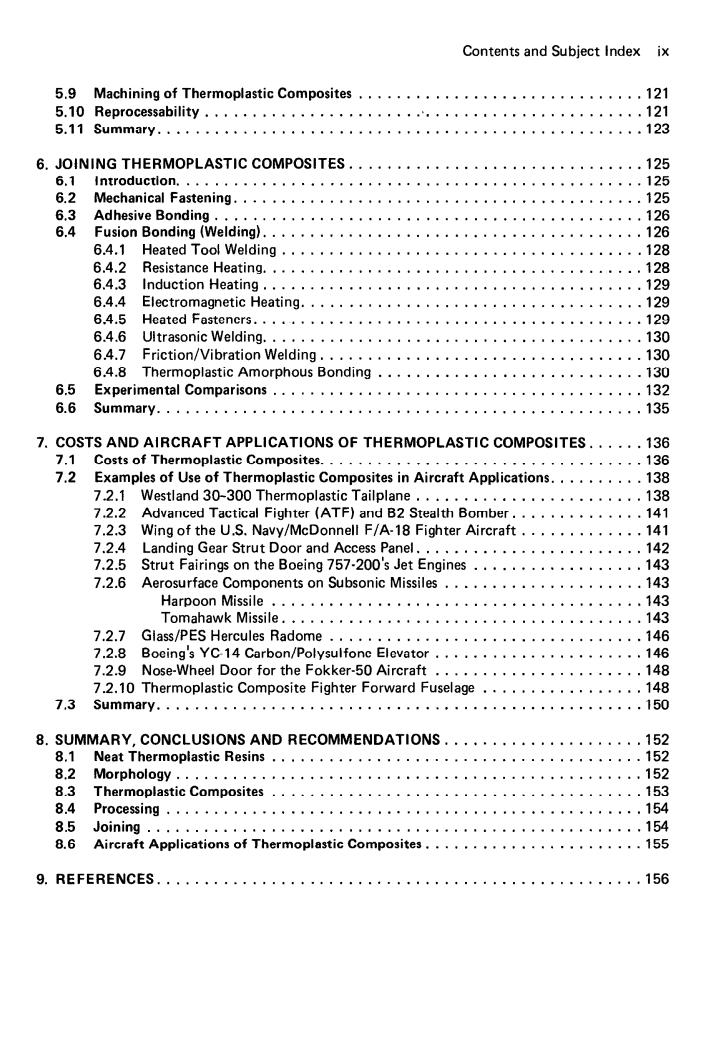

Contents and Subject Index ix 5.9 Machining of Thermoplastic Composites .............................. 121 5.10 Reprocessability ............................................... 121 5.11 Summary .................................................. .I23 6. JOINING THERMOPLASTIC COMPOSITES .............................. .I25 6.1 Introduction. ............................................... .I25 6.2 Mechanical Fastening. .......................................... 125 6.3 Adhesive Bonding. ........................................... .I26 6.4 Fusion Bonding (Welding). ....................................... 126 6.4.1 Heated Tool Welding ..................................... .I28 6.4.2 Resistance Heating. ....................................... 128 6.4.3 Induction Heating ........................................ 129 6.4.4 Electromagnetic Heating. ................................... 129 6.4.5 Heated Fasteners. ........................................ 129 6.4.6 Ultrasonic Welding. ....................................... 130 6.4.7 Friction/Vibration Welding. ................................. 130 6.4.8 Thermoplastic Amorphous Bonding ........................... .I30 6.5 Experimental Comparisons ....................................... 132 6.6 Summary. .................................................. 135 7. COSTS AND AIRCRAFT APPLICATIONS OF THERMOPLASTIC COMPOSITES. ..... 136 7.1 Costs of Thermoplastic Composites. ................................. 136 7.2 Examples of Use of Thermoplastic Composites in Aircraft Applications. ......... 138 7.2.1 Westland 30-300 Thermoplastic Tailplane ........................ 138 7.2.2 Advanced Tactical Fighter (ATF) and B2 Stealth Bomber. ............. 141 7.2.3 Wing of the U.S. Navy/McDonnell F/A-18 Fighter Aircraft ............. 141 7.2.4 Landing Gear Strut Door and Access Panel. ....................... 142 7.2.5 Strut Fairings on the Boeing 757-200’s Jet Engines .................. 143 7.2.6 Aerosurface Components on Subsonic Missiles ..................... 143 Harpoon Missile ...................................... .I43 Tomahawk Missile. .................................... .I43 7.2.7 Glass/PES Hercules Radome ................................ .I46 7.2.8 Boeing’s YC-14 Carbon/Polysulfone Elevator ...................... 146 7.2.9 Nose-Wheel Door for the Fokker-50 Aircraft ...................... 148 7.2.10 Thermoplastic Composite Fighter Forward Fuselage ................. 148 7.3 Summary...................................................15 0 8. SUMMARY, CONCLUSIONS AND RECOMMENDATIONS. ................... .I52 8.1 Neat Thermoplastic Resins ....................................... 152 8.2 Morphology ................................................ .I52 8.3 Thermoplastic Composites ...................................... .I53 8.4 Processing ................................................. .I54 8.5 Joining....................................................15 4 8.6 Aircraft Applications of Thermoplastic Composites. ...................... 155 9.REFERENCES...................................................156