6.Joining Thermoplastic Composites 6.1 Introduction Mechanical fastening and adhesive bonding,the commnon methods of joining thermoset based composites,are generally applicable to thermoplastic based composites.In addition to these joining methods.many new bonding techniques based on fusion bonding (welding)have been developed to join thermoplastic composite parts [104,236-238].These novel techniques include heated tool welding.resistance heating.induction heating. electromagnetic heating.heated fasteners,ultrasonic welding,friction vibration welding and thermoplastic amorphous bonding.They all take advantage of the unique feature of thermoplastics that allows them to be remelted and reprocessed. The choice of a joining method depends mainly on the application (loading,size and geometry of joint areas,reliability,cost,weight,...)and on the polymeric matrix that is used [236].Generally.mechanical fastening is preferred when high loads are expected.the joint region is small and/or high reliability is required.Adhesive and fusion bonding are preferred when weight and cost are important factors. The various methods to join composite parts either constituted of a thermoset matrix or thermoplastic matrix have been reviewed by Benatar [2361.Mechanical fastening.adhesive bonding and fusion bonding are well addressed.In a joint paper with Gutowski [2371.they investigated the various techniques for fusion bonding thermoplastic composites.Watson [238]presented a description of some of the welding techniques.In addition to these surveys. experimental studies have been conducted which compared these new joining methods for thermoplastic composites,particularly APC-2 composites [104,237,239].In this section,the recent developments concerning the techniques to join thermoplastic composites are presented.Although mechanical fastening and adhesive bonding are addressed,most of the content is directed towards fusion bonding methods. 6.2 Mechanical Fastening Mechanical fastening is a multi-step operation involving drilling holes and inserting and tightening fasteners [2361.It is an interesting method because no surface preparation is required,a joint is easy to inspect,the quality and strength of the joint are almost assured,it can be dissassembled and the joints are not adversely affected by thermal cycling and high humidity.However,fasteners add weight to the part and drilling damages the reinforcing fibres,weakens the part and creates stress concentrations.Walsh et al.[240]have conducted an experimental comparative assessment of bolted joints in carbon reinforced PEEK and epoxy (AS4/PEEK and IM6/3501-6 respectively).The thermoplastic composite showed superior 125

6. Joining Thermoplastic Composites 6.1 Introduction Mechanical fastening and adhesive bonding, the common methods of joining thermoset based composites, are generally applicable to thermoplastic based composites. In addition to these joining methods, many new bonding techniques based on fusion bonding (welding) have been developed to join thermoplastic composite parts [ 104, 236 - 2381. These novel techniques include heated tool welding, resistance heating, induction heating, electromagnetic heating, heated fasteners, ultrasonic welding, friction / vibration welding and thermoplastic amorphous bonding. They all take advantage of the unique feature of thermoplastics that allows them to be remelted and reprocessed. The choice of a joining method depends mainly on the application (loading, size and geometry ofjoint areas, reliability, cost, weight,...) and on the polymeric matrix that is used [236]. Generally, mechanical fastening is preferred when high loads are expected, the joint region is small and/or high reliability is required. Adhesive and fusion bonding are preferred when weight and cost are important factors. The various methods to join composite parts either constituted of a thermoset matrix or thermoplastic matrix have been reviewed by Benatar [236]. Mechanical fastening, adhesive bonding and fusion bonding are well addressed. In a joint paper with Gutowski 12371, they investigated the various techniques for fusion bonding thermoplastic composites. Watson 12381 presented a description of some of the welding techniques. In addition to these surreys, experimental studies have been conducted which compared these new joining methods for thermoplastic composites, particularly APC-2 composites [104, 237, 2391. In this section, the recent developments concerning the techniques to join thermoplastic composites are presented. Although mechanical fastening and adhesive bonding are addressed, most of the content is directed towards fusion bonding methods. 6.2 Mechanical Fastening Mechanical fastening is a multi-step operation involving drilling holes and inserting and tightening fasteners (2361. It is an interesting method because no surface preparation is required, a joint is easy to inspect, the quality and strength of the joint are almost assured, it can be dissassembled and the joints are not adversely affected by thermal cycling and high humidity. However, fasteners add weight to the part and drilling damages the reinforcing ilbres, weakens the part and creates stress concentrations. Walsh et al. [240] have conducted an experimental comparative assessment of bolted joints in carbon reinforced PEEK and epoxy (AS4/PEEK and IM6/3501-6 respectively). The thermoplastic composite showed superior 125

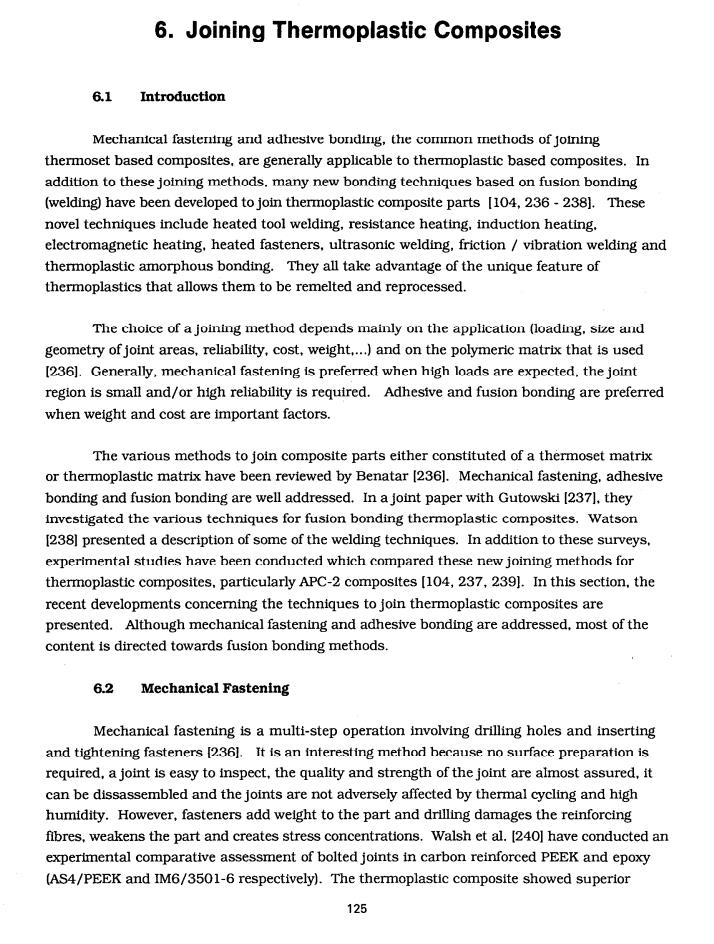

126 High Performance Thermoplastic Resins and Their Composites bolted joint performance to the epoxy composite.As shown in Figure 57.PEEK composites exhibited 10-15%higher bearing strength than the epoxy composites for both quasi-isotropic and0°/9o°laminates. 6.3 Adhesive Bonding Adhesive bonding is accomplished by placing an adhesive between the two parts to bc joined (the adherends).The load distribution of bonded joints is more uniform than mechanical fastened ones.Basically,the process involves four steps:i)surface preparation.a critical operation which ensures a good wetting of the adhesive to the adherend,ii)placement of the appropriate adhesive,iii)application of heat and/or pressure and iv)curing of the adhesive [2361.Experimental studies [103,241]have shown that conventional structural adhesives technology used for thermoset composites may be inadequate for thermoplastic composites.Due to their relative chemical inertness,it may be difficult to adhesively bond some thermoplastic composites with several of the currently used adhesives [239,241]. Adhesives used to bond thermoset composites are mostly thermosets and very often they are epoxy based adhesives [2361.Although several epoxy adhesives have shown compatibility with some thermoplastic composites in bonding processes [104.2421.the usage of an epoxy adhesive to join high performance thermoplastic composites may compromise the high temperature properties of the part and its water resistance.Using a thermoplastic matrix as an adhesive to bond thermoplastic composites presents several advantages.Among these are i)short processing time,ii)good thermal stability.iii)improved solvent resistance,iv)retention of bond strength at elevated temperature.v)low moisture absorption and vi)long shelf life. Kodokian and Kinloch [241]found that PEEK resin was a more effective adhesive in joining APC-2 composites than epoxy based adhesive.A similar observation was made when joining a ceramic plate to a metal case;a higher bond strength was obtained with PEEK film adhesive than with an epoxy [2431. 6.4 Fusion Bonding (Welding) Fusion bonding is a joining technique restricted to thermoplastic based composites where two or more parts are joined together by fusion and consolidation of their common interfaces (2441.As in adhesive bonding.it provides a more uniform load distribution than mechanically fastened joints but no additional new material,such as an adhesive,is involved. The fusion bonding techniques are faster and more easily automated than mechanical fastening and adhesive bonding techniques.The design of a welded joint is simllar to an adhesively bonded joint,i.e.single-lap,step-lap.double-lap and scarf joints can be used. Fracture analysis of welded joints assumes the same failure criterla that is used for mechanical fastening and adhesive bonding [236]

126 High Performance Thermoplastic Resins and Their Composites bolted joint performance to the epoxy composite. As shown in Figure 57. PEEK composites exhibited 10 - 15% higher bearing strength than the epoxy composites for both quasi-isotropic and 0”/90” laminates. 6.3 Adhesive Bonding Adhesive bonding is accomplished by placing an adhesive between the two parts to be joined (the adherends). The load distribution of bonded joints is more uniform than mechanical fastened ones. Basically, the process involves four steps: i) surface preparation, a critical operation which ensures a good wetting of the adhesive to the adherend. ii) placement of the appropriate adhesive, iii) application of heat and/or pressure and iv) curing of the adhesive [236). Experimental studies (103.241) have shown that conventional structural adhesives technology used for thermoset composites may be inadequate for thermoplastic composites. Due to their relative chemical inertness, it may be difficult to adhesively bond some thermoplastic composites with several of the currently used adhesives 1239, 24 11. Adhesives used to bond thermoset composites are mostly thermosets and very often they are epoxy based adhesives 1236). Although several epoxy adhesives have shown compatibility with some thermoplastic composites in bonding processes [104.242], the usage of an epoxy adhesive to join high performance thermoplastic composites may compromise the high temperature properties of the part and its water resistance. Using a thermoplastic matrix as an adhesive to bond thermoplastic composites presents several advantages. Among these are i) short processing time, ii) good thermal stability, iii) improved solvent resistance, iv) retention of bond strength at elevated temperature, v) low moisture absorption and vi) long shelf life. Kodokian and Kinloch [241) found that PEEK resin was a more effective adhesive in joining APC-2 composites than epoxy based adhesive. A similar observation was made when joining a ceramic plate to a metal case; a higher bond strength was obtained with PEEK ffirn adhesive than with an epoxy [243]. 6.4 Fusion Bonding (WeldingI Fusion bonding is a joining technique restricted to thermoplastic based composites where two or more parts are joined together by fusion and consolidation of their common interfaces 12441. As in adhesive bonding, it provides a more uniform load distribution than mechanically fastened joints but no additional new material, such as an adhesive, is involved. The fusion bonding techniques are faster and more easily automated than mechanical fastening and adhesive bonding techniques. The design of a welded joint is similar to an adhesively bonded joint, i.e. single-lap, step-lap, double-lap and scarfjoints can be used. Fracture analysis of welded joints assumes the same failure criteria that is used for mechanical fastening and adhesive bonding 12361

Joining Thermoplastic Composites 127 C Epoxy ☑ C PEEK 1200 1000 edW 800 600 400 200 ±45±45 Quasi Quasi 0/90 0/90 Specimen ID FIGURE 57.Bearing Strengths from Single Bolt Symmetric Double Lap Specimens [240]

Joining Thermoplastic Composites 127 I C EPOXY q CPEEK a 1000 B i 800 5 5 600 3 F 400 ‘Z t 200 m 0 +45 f45 Quasi Quasi O/90 O/90 Specimen ID FIGURE 57. Bearing Strengths from Single Bolt Symmetric Double Lap Specimens [240]

128 High Performance Thermoplastic Resins and Their Composites Although,there are a number of different welding techniques,they all involve 5 basic steps to establish a good bond between the thermoplastic composite parts [236,2371:1)surface preparation,heating.ii)pressing,iv)molecular diffusion and v)cooling.In general,the surface preparation is not as labor intensive as for adhesive bonding.Surface preparation is particularly important if the surfaces have been contaminated by a mold release agent. However.sanding of the surfaces is often sufficient.The energy to heat and melt thermoplastics can be supplied in many ways,but the most interesting methods are those which provide localized heating and melting only in the vicinity of the bond.This is rather difficult with carbon based composites due to the high thermal conductivity of the fibres. Warpage and deconsolidation away from the joint area may occur if small pressures(about.15 MPa)are not provided [236.237].Pressure has to be applied on the heated zones to bring the parts into contact,to permit the matrix to flow and to squeeze out any entrapped air.Once the surfaces of the composite parts to be joined are melted,complex molecular diffusion across the interfaces is necessary to form a good bond.During the final step of cooling.the applied load is maintained until warpage and deconsolidation cannot occur.Because fusion bonding involves only the interfaces of the parts to be joined,cooling rate of these small thermal masses is generally very fast,especially if carbon reinforcement (for which thermal diffusion is high)is used.Hence,cooling rate is an important issue in welding semi-crystalline thermoplastic composite parts. 6.4.1 Heated Tool Welding Heated tool welding is a simple process consisting of placing a hot tool in contact with and between the parts to be joined [236,238].The tool may be a flat hot plate or something more complex.Once the matrix is softened,the hot tool is withdrawn and the parts are pressed together.The high cooling rate of the surfaces especially when reinforced with carbon fibres, renders the process suitable for small parts [2361.The process is relatively slow [238];weld times range from 10 to 20 seconds for small parts and to 30 minutes for larger parts. 6.4.2 Resistance Heating Resistance heating consists of introducing a resistive element between the laminates to be bonded and applying an electric current through this element [104,236,237,239,2441. Because the element remains between the two parts,it has to be compatible with the composites.Single carbon/thermoplastic prepreg tape that may be covered by a thin polymer film can be used as the resistive element.The fibres act as resistance heaters and melt the matrix.Electrical heating must be sufficlent to melt the matrix in the single ply,the surface of the laminates and the matrix film.Under pressure,welding of the two parts is achieved. Resistance heating is a relatively simple and fast process,requiring little surface preparation (sanding of the surfaces is sufficient)and incurs low costs

128 High Performance Thermoplastic Resins and Their Composites Although, there are a number of diiferent welding techniques, they all involve 5 basic steps to establish a good bond between the thermoplastic composite parts (236,237): i) surface preparation, ii) heating, iii) pressing, iv) molecular diffusion and v) cooling. In general, the surface preparation is not as labor intensive as for adhesive bonding. Surface preparation is particularly important if the surfaces have been contaminated by a mold release agent. However, sanding of the surfaces is often sufficient. The energy to heat and melt thermoplastics can be supplied in many ways, but the most interesting methods are those which provide localized heating and melting only in the vicinity of the bond. This is rather ditIIcult with carbon based composites due to the high thermal conductivity of the fibres. War-page and deconsolidation away from the joint area may occur if small pressures (about .15 MPa) are not provided [236.237]. Pressure has to be applied on the heated zones to bring the parts into contact, to permit the matrix to flow and to squeeze out any entrapped air. Once the surfaces of the composite parts to be joined are melted, complex molecular diffusion across the interfaces is necessary to form a good bond. During the final step of cooling, the applied load is maintained until warpage and deconsolidation cannot occur. Because fusion bonding involves only the interfaces of the parts to be joined, cooling rate of these small thermal masses is generally very fast, especially if carbon reinforcement (for which thermal diffusion is high) is used. Hence, cooling rate is an important Issue in welding semi-crystalline thermoplastic composite parts. 6.4.1 Heated Tool Welding Heated tool welding is a simple process consisting of placing a hot tool in contact with and between the parts to be joined [236,238). The tool may be a flat hot plate or something more complex Once the matrix is softened, the hot tool is withdrawn and the parts are pressed together. The high cooling rate of the surfaces especially when reinforced with carbon fibres, renders the process suitable for small parts [2361. The process is relatively slow [238]: weld times range from 10 to 20 seconds for small parts and to 30 minutes for larger parts. 6.4.2 Resistance Heating Resistance heating consists of introducing a resistive element between the laminates to be bonded and applying an electric current through this element (104,236.237.239.244]. Because the element remains between the two parts, it has to be compatible with the composites. Single carbon/thermoplastic prepreg tape that may be covered by a thin polymer film can be used as the resistive element. The fibres act as resistance heaters and melt the matrix. Electrical heating must be sufficient to melt the matrix in the single ply. the surface of the laminates and the matrix film. Under pressure, welding of the two parts is achieved. Resistance heating is a relatively simple and fast process, requiring little surface preparation (sanding of the surfaces is suificient) and incurs low costs

Joining Thermoplastic Composites 129 Maffezzoli et al.[245]have developed a mathematical model to describe the resistance heating process of APC-2 laminates.The model which accounts for heat generation due to the electrical heating.thermal diffusion inside the composite and phase changes in the polymeric matrix enables the prediction of temperature profiles and crystallinity contents in the final materlal for the different processing conditions. 6.4.3 Induction Heating Induction heating consists of the generation of eddy currents within a conductor by a magnetic field [236,237,239].The conductor is heated as the eddy currents dissipate due to the internal electrical resistance.As for resistance welding,the conductor has to be compatible with the composite since it will remain embedded between the composite parts.To only heat the interfaces and not the whole laminates,the conductive material has to be more conductive than carbon fibres.Nickel coated carbon fibres or a metal screen may be used but in general these materials are not fully compatible with the thermoplastic composites and may reduce the strength of the bond. 6.4.4 Electromagnetic Heating Electromagnetic fields are often used to heat and melt thermoplastics.The surfaces to be bonded are exposed to an electromagnetic field involving either microwave,laser radiation or infrared lamps [104.236,2371.The motions of the excited molecules heat up the material. When the thermoplastic is molten,the parts are pressed together and cooled. Depending on the composite and on the frequency of the electromagnetic field.this method may not be effective.For example,the incorporation of carbon fibres into a thermoplastic matrix renders the composite much too conductive.When exposed to microwave heating,the carbon reinforced composite acts as a shield to these electomagnetic waves. 6.4.5 Heated Fasteners Although it requires some improvement,this techniquc is very attractive [236,2371. Metallic fasteners are used to mechanically join thermoplastic composite parts.Once in place the fasteners are heated and melt the thermoplastic around them.This technique provides both mechanical and fusion bonding.Although the fasteners or inserts would be very small in size and could be easily inserted into the composite,an insertion method has to be developed to minimize the damage to the fibres from installing these fasteners

Joining Thermoplastic Composites 129 Maifezzoli et al. 12451 have developed a mathematical model to describe the resistance heating process of APC-2 laminates. The model which accounts for heat generation due to the electrical heating, thermal diffusion inside the composite and phase changes in the polymeric matrix enables the prediction of temperature profiles and crystallinity contents in the final material for the different processing conditions. 6.4.3 Induction Heating Induction heating consists of the generation of eddy currents within a conductor by a magnetic field [236, 237, 2391. The conductor is heated as the eddy currents dissipate due to the internal electrical resistance. As for resistance welding, the conductor has to be compatible with the composite since it will remain embedded between the composite parts. To only heat the interfaces and not the whole laminates, the conductive material has to be more conductive than carbon fibres. Nickel coated carbon iibres or a metal screen may be used but in general these materials are not fully compatible with the thermoplastic composites and may reduce the strength of the bond. 6.4.4 Electromagnetic Heating Electromagnetic fields are often used to heat and melt thermoplastics. The surfaces to be bonded are exposed to an electromagnetic field involving either microwave, laser radiation or infrared lamps [ 104, 236, 2371. The motions of the excited molecules heat up the material. When the thermoplastic is molten, the parts are pressed together and cooled. Depending on the composite and on the frequency of the electromagnetic field, this method may not be effective. For example, the incorporation of carbon fibres into a thermoplastic matrix renders the composite much too conductive. When exposed to microwave heating, the carbon reinforced composite acts as a shield to these electomagnetic waves. 6.4.5 Heated Fasteners Although it requires some improvement, this technique is very attractive 1236. 2373. Metallic fasteners are used to mechanically join thermoplastic composite parts. Once in place the fasteners are heated and melt the thermoplastic around them. This technique provides both mechanical and fusion bonding. Although the fasteners or inserts would be very small in size and could be easily inserted into the composite, an insertion method has to be developed to minimize the damage to the fibres from installing these fasteners

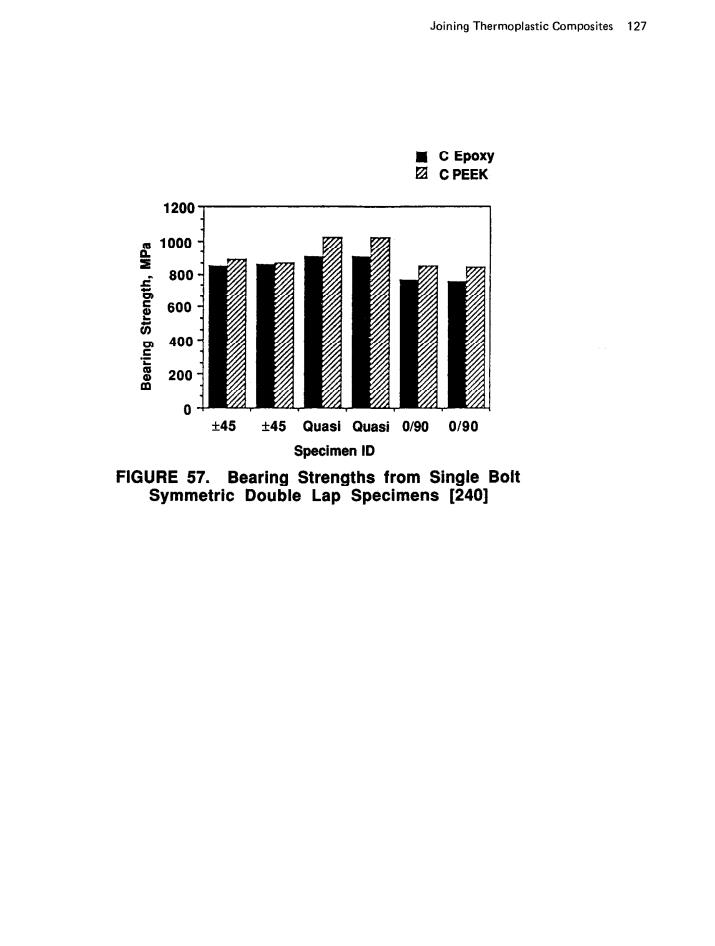

130 High Performance Thermoplastic Resins and Their Composites 6.4.6 Ultrasonic Welding Ultrasonic welding is one of the most widely used techniques for joining thermoplastics [246J.In using this technique,parts to be assembled are held together under pressure and are subjected to ultrasonic vibrations [104,236,237,238,2461.These high frequency mechanical vibrations,usually greater than 18 kHz [238,246].cause surface and intermolecular frictions which generate heat.Heat is generated at the desired location at the weld interface,by the addition of wedge shaped thermoplastic protrustons called energy directors(Figure 58).When above the melting temperature,the thermoplastic matrix flows and solidifies after the vibrations stop. 6.4.7 Friction/Vibration Welding This technique consists in the generation of heat by rubbing together the two parts to be joined [236.238.239].The two parts are held together under pressure and the relative vibrational motion generates heat.Friction welding refers to rotational motion while vibration welding consists of linear oscillations.Vibration frequencies are typically between 100-240 Hz [2381.Once the matrix is molten the motion is stopped,then the parts are aligned and the interfaces solidify during cooling.Sometimes,the motion may result in some fibre misalignment but this can be reduced by adding a resin rich layer at the bond surface. 6.4.8 Thermoplastic Amorphous Bonding Thermoplastic amorphous bonding is a novel technique that has been applied to APC-2 composites [104,206.244].In this process.a polyetherimide (PEI)film,an amorphous thermoplastic resin,is placed on the surface during lay-up and co-consolidated with the APC-2 parts to be welded.The two parts are subsequently bonded at a temperature above the Tg of PEI (210C)but well below the melting temperature of PEEK(340C).Hence the APC-2 parts do not melt and they retain superior dimensional tolerances and fibre orientation in the vicinity of the weld interface [206,2441.This technique produces good joint strength [104,206,244]and requires minimal equipment.In the experimental study of Don et al.[244].APC-2/PEI resistance welded specimens produced slightly lower lap shear strength (35.9t 1.0 MPa)than resistance welded APC-2 with PEEK film(44.8 t 7.6 MPa),but the results were more reproducible and no fibre movement was detected as was the case with APC-2/PEEK. Thermoplastic amorphous bonding has the major disadvantage of reducing the solvent resistance of the joined APC-2 composite parts compared to the semi-crystalline joint obtained with PEEK film [2441.No other amorphous thermoplastics other than PEI used to bond APC-2 composites was found in this literature search.However,perhaps amorphous thermoplastics having a Tg closer to,but still less than the melting temperature of the parts to be bonded may give better performance

130 High Performance Thermoplastic Resins and Their Composites 6.4.6 Ultrasonic Welding Ultrasonic welding is one of the most widely used techniques for joining thermoplastics [246]. In using this technique, parts to be assembled are held together under pressure and are subjected to ultrasonic vibrations (104, 236,237, 238.2463. These high frequency mechanical vibrations, usually greater than 18 kHz [238, 2461, cause surface and intermolecular frictions which generate heat. Heat is generated at the desired location at the weld interface, by the addition of wedge shaped thermoplastic protrusions called energy directors (Figure 58). When above the melting temperature, the thermoplastic matrix flows and solidifies after the vibrations stop. 6.4.7 Friction/Vibration Welding This technique consists in the generation of heat by rubbing together the two parts to be joined [236,238,239]. The two parts are held together under pressure and the relative vibrational motion generates heat. Friction welding refers to rotational motion while vibration welding consists of linear oscillations. Vibration frequencies are typically between 100 - 240 Hz [238]. Once the matrix is molten the motion is stopped, then the parts are aligned and the interfaces solidify during cooling. Sometimes, the motion may result in some fibre misalignment but this can be reduced by adding a resin rich layer at the bond surface. 6.4.8 Thermoplastic Amorphous Bonding Thermoplastic amorphous bonding is a novel technique that has been applied to APC-2 composites [104,206.244]. In this process, a polyetherimide (PEI) film, an amorphous thermoplastic resin, is placed on the surface during lay-up and co-consolidated with the APC-2 parts to be welded. The two parts are subsequently bonded at a temperature above the Tg of PEI (2 10’ C) but well below the melting temperature of PEEK (340” C). Hence the APC-2 parts do not melt and they retain superior dimensional tolerances and fibre orientation in the vicinity of the weld interface [ZOS, 2443. This technique produces good joint strength [104,206, 2441 and requires minimal equipment. In the experimental study of Don et al. (2441. APC-P/PEI resistance welded specimens produced slightly lower lap shear strength (35.9 _+ 1.0 MPa) than resistance welded APC-2 with PEEK film (44.8 k 7.6 MPa), but the results were more reproducible and no fibre movement was detected as was the case with APC-2/PEEK. Thermoplastic amorphous bonding has the major disadvantage of reducing the solvent resistance of the joined APC-2 composite parts compared to the semi-crystalline joint obtained with PEEK film (2441. No other amorphous thermoplastics other than PEI used to bond APC-2 composites was found in this literature search. However, perhaps amorphous thermoplastics having a Tg closer to, but still less than the melting temperature of the parts to be bonded may give better performance

Joining Thermoplastic Composites 131 Part 1 Energy Director Part 2 FIGURE 58.Typical Configuration of Parts During Ultrasonic Welding [236] 4 MIXED TYPES Air Entrapment FIGURE 59.Various Types of Melt Front Propagation [246]

Joining Thermoplastic Composites 131 I Part 1 I FIGURE 58. Typical Configuration of Parts During Ultrasonic Welding [236] 3 4 MIXED TYPES FIGURE 59. Various Types of Melt Front Propagation [246]

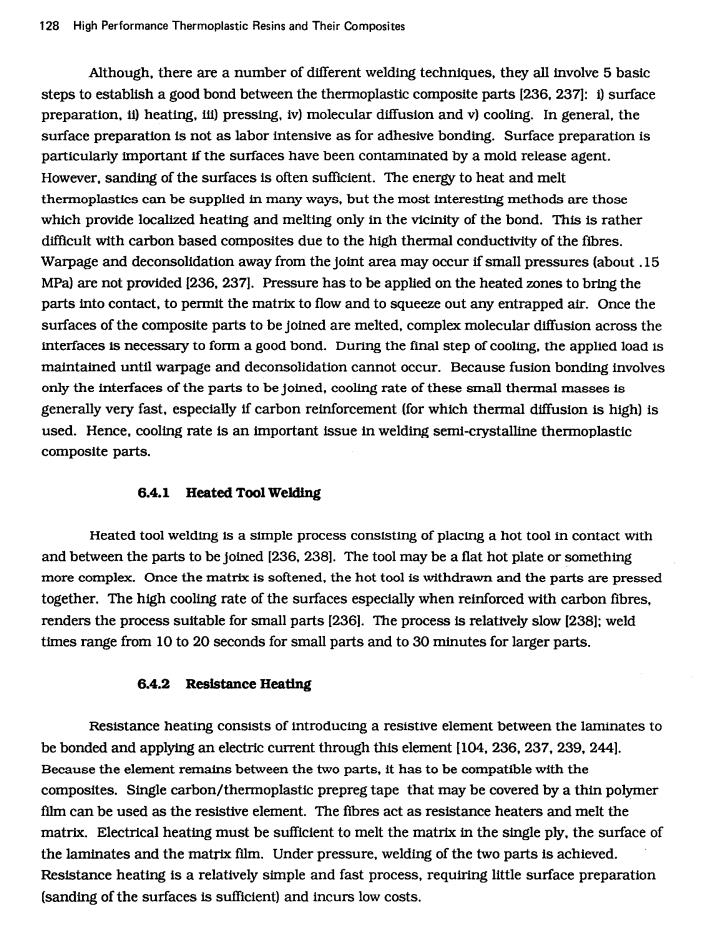

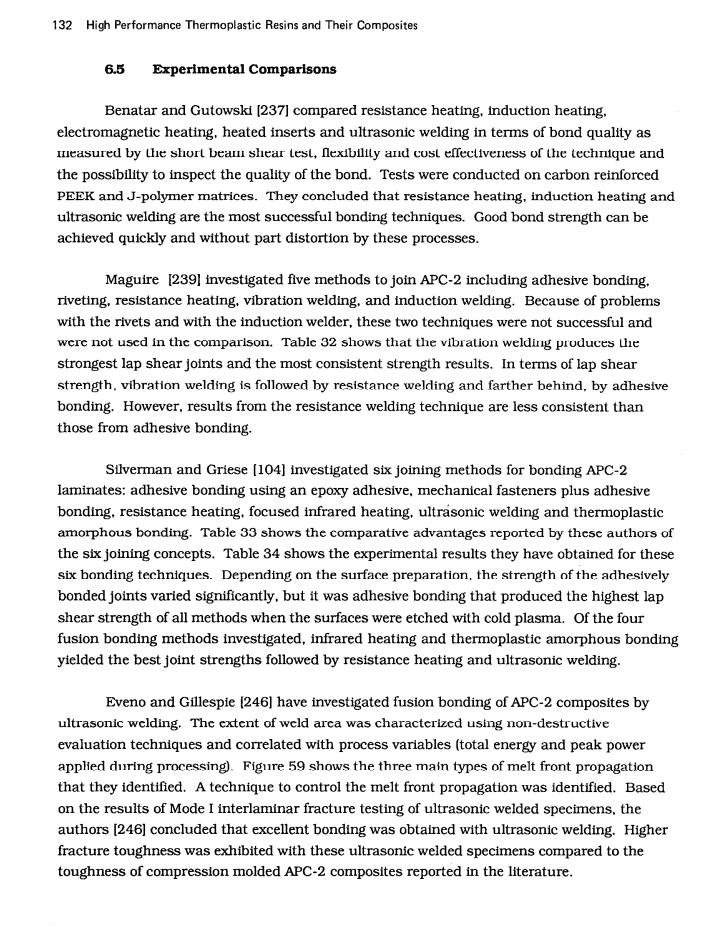

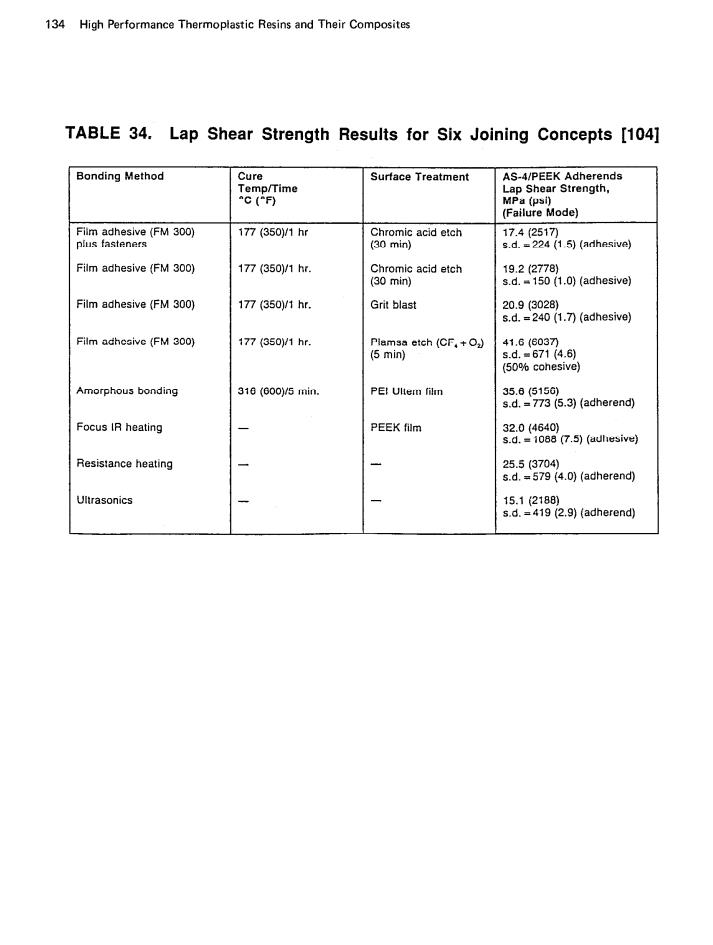

132 High Performance Thermoplastic Resins and Their Composites 6.5 Experimental Comparisons Benatar and Gutowski[237]compared resistance heating,induction heating. electromagnetic heating,heated inserts and ultrasonic welding in terms of bond quality as measured by the short beam shear lest,flexibility and cost effectiveness of the technque and the possibility to inspect the quality of the bond.Tests were conducted on carbon reinforced PEEK and J-polymer matrices.They concluded that resistance heating,induction heating and ultrasonic welding are the most successful bonding techniques.Good bond strength can be achieved quickly and without part distortion by these processes. Maguire [239]investigated five methods to join APC-2 including adhesive bonding. riveting,resistance heating,vibration welding,and induction welding.Because of problems with the rivets and with the induction welder,these two techniques were not successful and were not used in the comparison.Table 32 shows that the vibration welding produces the strongest lap shear joints and the most consistent strength results.In terms of lap shear strength.vibration welding is followed by resistance welding and farther behind,by adhesive bonding.However,results from the resistance welding technique are less consistent than those from adhesive bonding. Silverman and Griese [104]investigated six joining methods for bonding APC-2 laminates:adhesive bonding using an epoxy adhesive,mechanical fasteners plus adhesive bonding,resistance heating.focused infrared heating.ultrasonic welding and thermoplastic amorphous bonding.Table 33 shows the comparative advantages reported by thesc authors of the six joining concepts.Table 34 shows the experimental results they have obtained for these six bonding techniques.Depending on the surface preparation.the strength of the adhesively bonded joints varied significantly,but it was adhesive bonding that produced the highest lap shear strength of all methods when the surfaces were etched with cold plasma.Of the four fusion bonding methods investigated,infrared heating and thermoplastic amorphous bonding yielded the best joint strengths followed by resistance heating and ultrasonic welding Eveno and Gillespie (246]have investigated fusion bonding of APC-2 composites by ultrasonic welding.The extent of weld arca was characterized using non-destructive evaluation techniques and correlated with process variables (total energy and peak power applied during processing).Figure 59 shows the three main types of melt front propagation that they identified.A technique to control the melt front propagation was identified.Based on the results of Mode I interlaminar fracture testing of ultrasonic welded specimens.the authors [246]concluded that excellent bonding was obtained with ultrasonic welding.Higher fracture toughness was exhibited with these ultrasonic welded specimens compared to the toughness of compression molded APC-2 composites reported in the literature

132 High Performance Thermoplastic Resins and Their Composites 6.5 Experimental Comparisons Benatar and Gutowski 12371 compared resistance heating, Induction heating, electromagnetic heating, heated inserts and ultrasonic welding in terms of bond quality as measured by the short beam shear test, flexibility and cost effectiveness of the technique and the possibility to Inspect the quality of the bond. Tests were conducted on carbon reinforced PEEK and J-polymer matrices. They concluded that resistance heating, Induction heating and ultrasonic welding are the most successful bonding techniques. Good bond strength can be achieved quickly and without part distortion by these processes. Maguire 12391 Investigated five methods to join APC-2 including adhesive bonding, riveting, resistance heating, vibration welding, and induction welding. Because of problems with the rivets and with the induction welder, these two techniques were not successful and were not used in the comparison. Table 32 shows that the vibration welding produces the strongest lap shear joints and the most consistent strength results. In terms of lap shear strength, vibration welding is followed by resistance welding and farther behind, by adhesive bonding. However, results from the resistance welding technique are less consistent than those from adhesive bonding. Silverman and Griese [ 1041 investigated six joining methods for bonding APC-2 laminates: adhesive bonding using an epoxy adhesive, mechanical fasteners plus adhesive bonding, resistance heating, focused infrared heating, ultrasonic welding and thermoplastic amorphous bonding. Table 33 shows the comparative advantages reported by these authors of the six joining concepts. Table 34 shows the experimental results they have obtained for these six bonding techniques. Depending on the surface preparation, the strength of the adhesively bonded joints varied significantly, but it was adhesive bonding that produced the highest lap shear strength of all methods when the surfaces were etched with cold plasma. Of the four fusion bonding methods investigated, infrared heating and thermoplastic amorphous bonding yielded the best joint strengths followed by resistance heating and ultrasonic welding. Eveno and Gillespie 12461 have Investigated fusion bonding of APC-2 composites by ultrasonic welding. The extent of weld area was characterized using non-destructive evaluation techniques and correlated with process variables (total energy and peak power applied during processing). Figure 59 shows the three main types of melt front propagation that they identified. A technique to control the melt front propagation was identified. Based on the results of Mode I interlaminar fracture testing of ultrasonic welded specimens, the authors 12461 concluded that excellent bonding was obtained with ultrasonic welding. Higher fracture toughness was exhibited with these ultrasonic welded specimens compared to the toughness of compression molded APC-2 composites reported in the literature

Joining Thermoplastic Composites 133 TABLE 32.Lap Shear Strength Results for Three Joining Techniques [239] Graphite 3M3569 Resistance Vibration Adheslve Welded Welded Average Lap Shear Strength MPa(psi) 15.75(2284) 23.88(3464) 39.29(5699 Coefficient of Variation(%) 8.8 44.7 7.7 TABLE 33.Comparative Advantages of Six Joining Concepts [104] Reproducibility Suitable for Small and Adaptable to Various Minimal Surface Preparation Large Area Bonding Joint Configurations Adaptable to Automation Minimal Equipment Use On-Line inspection Capability Reworkability Production Environment Adhesive Bonding 10 10 10 Yes 10 No Yes Fasteners Plus Adhesive 10 Yes 10 No Yes Resistance Heating 5 8 8 10 Yes 5 No Ultrasonic Welding 5 5 5 Yes 10 名 Focused IR 10 4 10 Yes 5 Yes Yes Amorphous Thermoplastic Film 10 10 o b 10 Yes 10 Yes Yes 0-Lowest,10-Highest

Joining Thermoplastic Composites 133 TABLE 32. Lap Shear Strength Results for Three Joining Techniques [239] 3M 3569 Adheslve Graphite Resistance Welded Vibration, Welded Average Lap Shear Strength MPa (psi) 15.75 (2284) 23.88 (3464) 39.29 (5699) Coefficient of Variation (%) 8.8 44.7 7.7 TABLE 33. Comparative Advantages of Six Joining Concepts [104] Adhesive Bonding I 10’ Fasteners Plus Adhesive 10 Resistance Heating 5 Ultrasonic Welding I 5 Focused IA 10 Amorphous Thermoplastic Film I 10 9 s / .! 0 9, 10 3 $ i or 0 i? / .! $ 1 1 10 10 10 10 Yes Yes No No Yes Yes I ‘o= Lowest, lO=Highesl

134 High Performance Thermoplastic Resins and Their Composites TABLE 34.Lap Shear Strength Results for Six Joining Concepts [104] Bonding Method Cure Surface Treatment AS-4/PEEK Adherends Temp/Time Lap Shear Strength, C("F) MPa (psi) (Failure Mode) Film adhesive (FM 300) 177(350/1hr Chromic acid etch 17.42517) plus fasteners (30min) s.d.=224 (1.5)(adhesive) Film adhesive (FM 300) 177(350)/1h. Chromic acid etch 19.22778) (30 min) s.d.=150 (1.0)(adhesive) Film adhesive (FM 300) 177(350/1hr. Grit blast 20.9(3028) s.d.=240 (1.7)(adhesive) Film adhesive (FM 300) 177(350V1hr. Plamsa etch (CF,+O) 41.6(6037 (5 min) s.d.■671(4.6) (50%cohesive) Amorphous bonding 316(600)/5mim. PE!Ullem film 35.6(515G s.d.=773 (5.3)(adherend) Focus IR heating PEEK film 32.0(4640) s.d.=1088 (7.5)(aulesive) Resistance heating 25.5(3704) s.d.=579 (4.0)(adherend) Ultrasonics 15.12188) s.d.=419 (2.9)(adherend)

134 High Performance Thermoplastic Resins and Their Composites TABLE 34. Lap Shear Strength Results for Six Joining Concepts [104] Bonding Method Film adhesive (FM 300) plus fasteners Film adhesive (FM 300) Film adhesive (FM 300) Cure Tamp/Time ‘C (“F) 177 (350)/i hr 177 (350)/l hr. 177 (350)/i hr. Surface Treatment Chromic acid etch (30 min) Chromic acid etch (30 min) Grit blast AS-4IPEEK Adherends Lap Shear Strength, MPa (psi) (Failure Mode) 17.4 (2517) s.d. = 224 (1.5) (adhesive) 19.2 (2778) s.d. = 150 (1.0) (adhesive) 20.9 (3028) s.d. = 240 (1.7) (adhesive) Film adhesive (FM 300) 177 (350)/i hr. Plamsa etch (CF. + OJ 41.6 (6037) (5 min) s.d. =671 (4.6) (50% cohesive) Amorphous bonding 316 (600)/5 min. PEI Ultem film 35.6 (5156) s.d. =773 (5.3) (adherend) Focus IR heating - PEEK film 32.0 (4640) s.d. = 1088 (7.5) (adhesive) Resistance heating - 25.5 (3704) s.d. =579 (4.0) (adherend) Ultrasonics - - 15.1 (2188) s.d. =419 (2.9) (adherend)