正在加载图片...

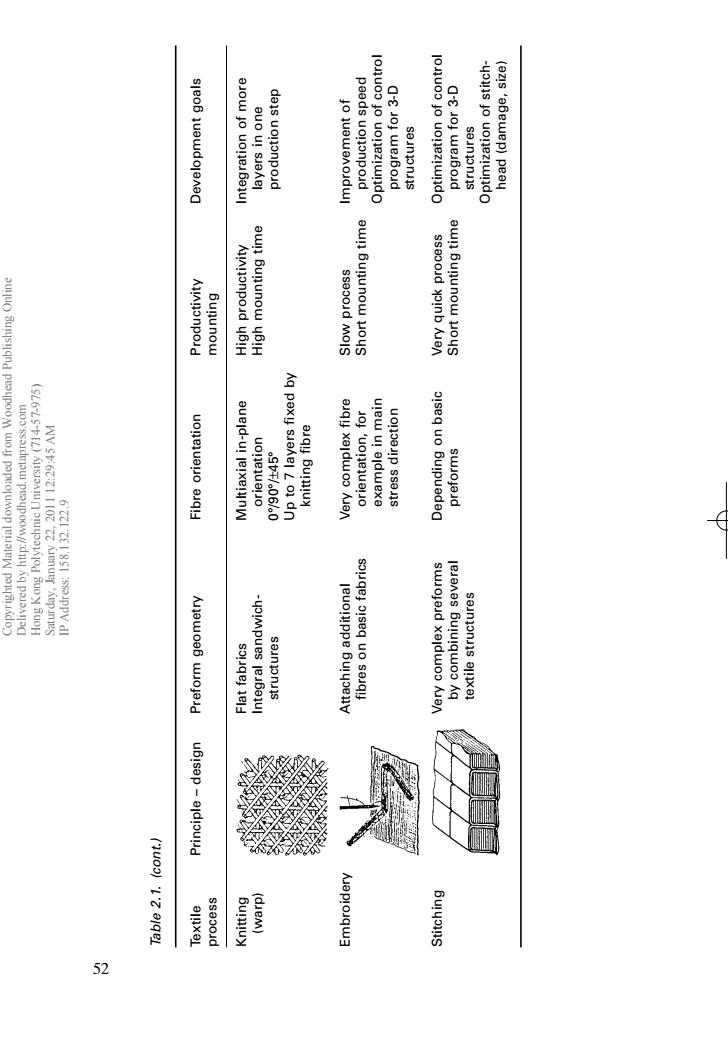

auo ul sJeAel senons (azis 'a6ewep)peay 6ununow ewn Bununow joys WVSt:6Z:ZI I 10Z 'ZZ KIenunr 'Kupines ulew u!aldwexe uonloeJip ssens oiseq uo 6u!puadea 6'ZZI'ZEI'8SI :ssappy dl -yoIMpues leJBajul seunjonJis (dieM) 52Table 2.1. (cont.) Textile Principle – design Preform geometry Fibre orientation Productivity Development goals process mounting Knitting Flat fabrics Multiaxial in-plane High productivity Integration of more (warp) Integral sandwich- orientation High mounting time layers in one structures 0°/90°/±45° production step Up to 7 layers fixed by knitting fibre Embroidery Attaching additional Very complex fibre Slow process Improvement of fibres on basic fabrics orientation, for Short mounting time production speed example in main Optimization of control stress direction program for 3-D structures Stitching Very complex preforms Depending on basic Very quick process Optimization of control by combining several preforms Short mounting time program for 3-D textile structures structures Optimization of stitchhead (damage, size) 52 RIC2 7/10/99 7:25 PM Page 52 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9