正在加载图片...

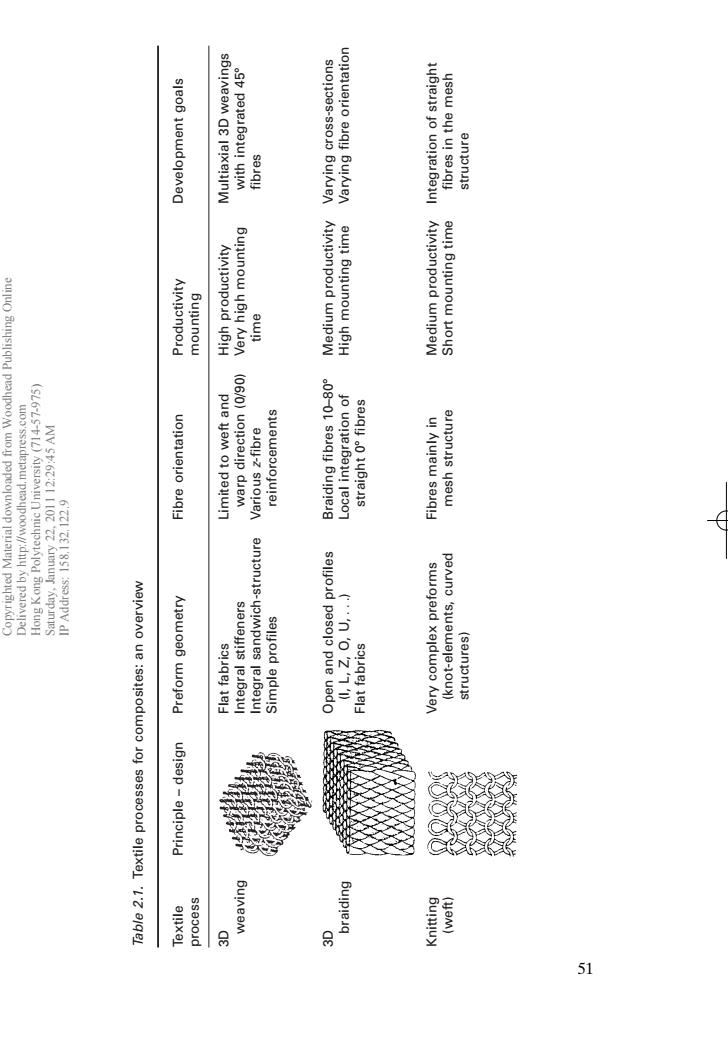

s6u!eaM OE leixeninW enjonns Bununow ewn 6ununow y6!H woo'ssaidmau'peaypoow//:dny Aq paranad WVSt:6Z:ZI I 10Z 'ZZ KIenunr 'Kupines pue yem o1 peuw! eqy-z snole 6'ZZI'ZEI'8SI :ssauppy dl (noZ7 souqej iely (seunjonjis 品 号 51Table 2.1. Textile processes for composites: an overview Textile Principle – design Preform geometry Fibre orientation Productivity Development goals process mounting 3D Flat fabrics Limited to weft and High productivity Multiaxial 3D weavings weaving Integral stiffeners warp direction (0/90) Very high mounting with integrated 45° Integral sandwich-structure Various z-fibre time fibres Simple profiles reinforcements 3D Open and closed profiles Braiding fibres 10–80° Medium productivity Varying cross-sections braiding (I, L, Z, O, U, ...) Local integration of High mounting time Varying fibre orientation Flat fabrics straight 0° fibres Knitting Very complex preforms Fibres mainly in Medium productivity Integration of straight (weft) (knot-elements, curved mesh structure Short mounting time fibres in the mesh structures) structure 51 RIC2 7/10/99 7:25 PM Page 51 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9