正在加载图片...

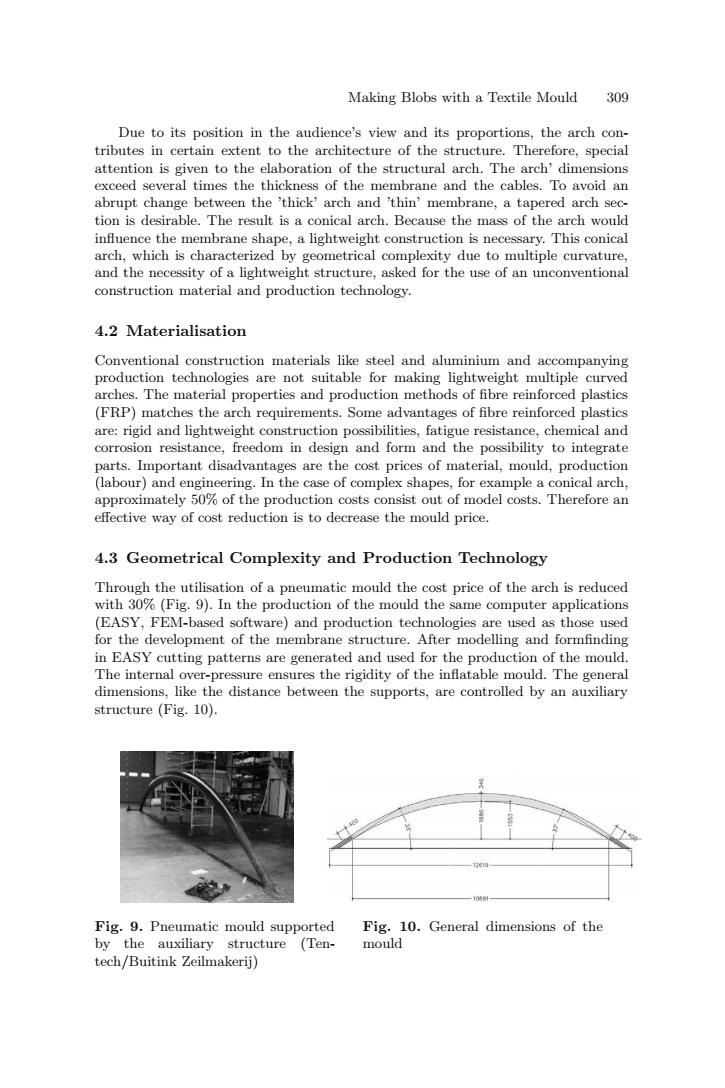

Making Blobs with a Textile Mould 309 Due to its position in the audience's view and its proportions,the arch con- tributes in certain extent to the architecture of the structure.Therefore,special attention is given to the elaboration of the structural arch.The arch'dimensions exceed several times the thickness of the membrane and the cables.To avoid an abrupt change between the 'thick'arch and 'thin'membrane,a tapered arch sec- tion is desirable.The result is a conical arch.Because the mass of the arch would influence the membrane shape,a lightweight construction is necessary.This conical arch,which is characterized by geometrical complexity due to multiple curvature, and the necessity of a lightweight structure.asked for the use of an unconventional construction material and production technology. 4.2 Materialisation Conventional construction materials like steel and aluminium and accompanying production technologies are not suitable for making lightweight multiple curved arches.The material properties and production methods of fibre reinforced plastics (FRP)matches the arch requirements.Some advantages of fibre reinforced plastics are:rigid and lightweight construction possibilities,fatigue resistance,chemical and corrosion resistance,freedom in design and form and the possibility to integrate parts.Important disadvantages are the cost prices of material,mould,production (labour)and engineering.In the case of complex shapes,for example a conical arch, approximately 50%of the production costs consist out of model costs.Therefore an effective way of cost reduction is to decrease the mould price. 4.3 Geometrical Complexity and Production Technology Through the utilisation of a pneumatic mould the cost price of the arch is reduced with 30%(Fig.9).In the production of the mould the same computer applications (EASY,FEM-based software)and production technologies are used as those used for the development of the membrane structure.After modelling and formfinding in EASY cutting patterns are generated and used for the production of the mould. The internal over-pressure ensures the rigidity of the inflatable mould.The general dimensions,like the distance between the supports,are controlled by an auxiliary structure (Fig.10). 100 Fig.9.Pneumatic mould supported Fig.10.General dimensions of the by the auxiliary structure (Ten- mould tech/Buitink Zeilmakerij)Making Blobs with a Textile Mould 309 Due to its position in the audience’s view and its proportions, the arch contributes in certain extent to the architecture of the structure. Therefore, special attention is given to the elaboration of the structural arch. The arch’ dimensions exceed several times the thickness of the membrane and the cables. To avoid an abrupt change between the ’thick’ arch and ’thin’ membrane, a tapered arch section is desirable. The result is a conical arch. Because the mass of the arch would influence the membrane shape, a lightweight construction is necessary. This conical arch, which is characterized by geometrical complexity due to multiple curvature, and the necessity of a lightweight structure, asked for the use of an unconventional construction material and production technology. 4.2 Materialisation Conventional construction materials like steel and aluminium and accompanying production technologies are not suitable for making lightweight multiple curved arches. The material properties and production methods of fibre reinforced plastics (FRP) matches the arch requirements. Some advantages of fibre reinforced plastics are: rigid and lightweight construction possibilities, fatigue resistance, chemical and corrosion resistance, freedom in design and form and the possibility to integrate parts. Important disadvantages are the cost prices of material, mould, production (labour) and engineering. In the case of complex shapes, for example a conical arch, approximately 50% of the production costs consist out of model costs. Therefore an effective way of cost reduction is to decrease the mould price. 4.3 Geometrical Complexity and Production Technology Through the utilisation of a pneumatic mould the cost price of the arch is reduced with 30% (Fig. 9). In the production of the mould the same computer applications (EASY, FEM-based software) and production technologies are used as those used for the development of the membrane structure. After modelling and formfinding in EASY cutting patterns are generated and used for the production of the mould. The internal over-pressure ensures the rigidity of the inflatable mould. The general dimensions, like the distance between the supports, are controlled by an auxiliary structure (Fig. 10). Fig. 9. Pneumatic mould supported by the auxiliary structure (Tentech/Buitink Zeilmakerij) Fig. 10. General dimensions of the mould