正在加载图片...

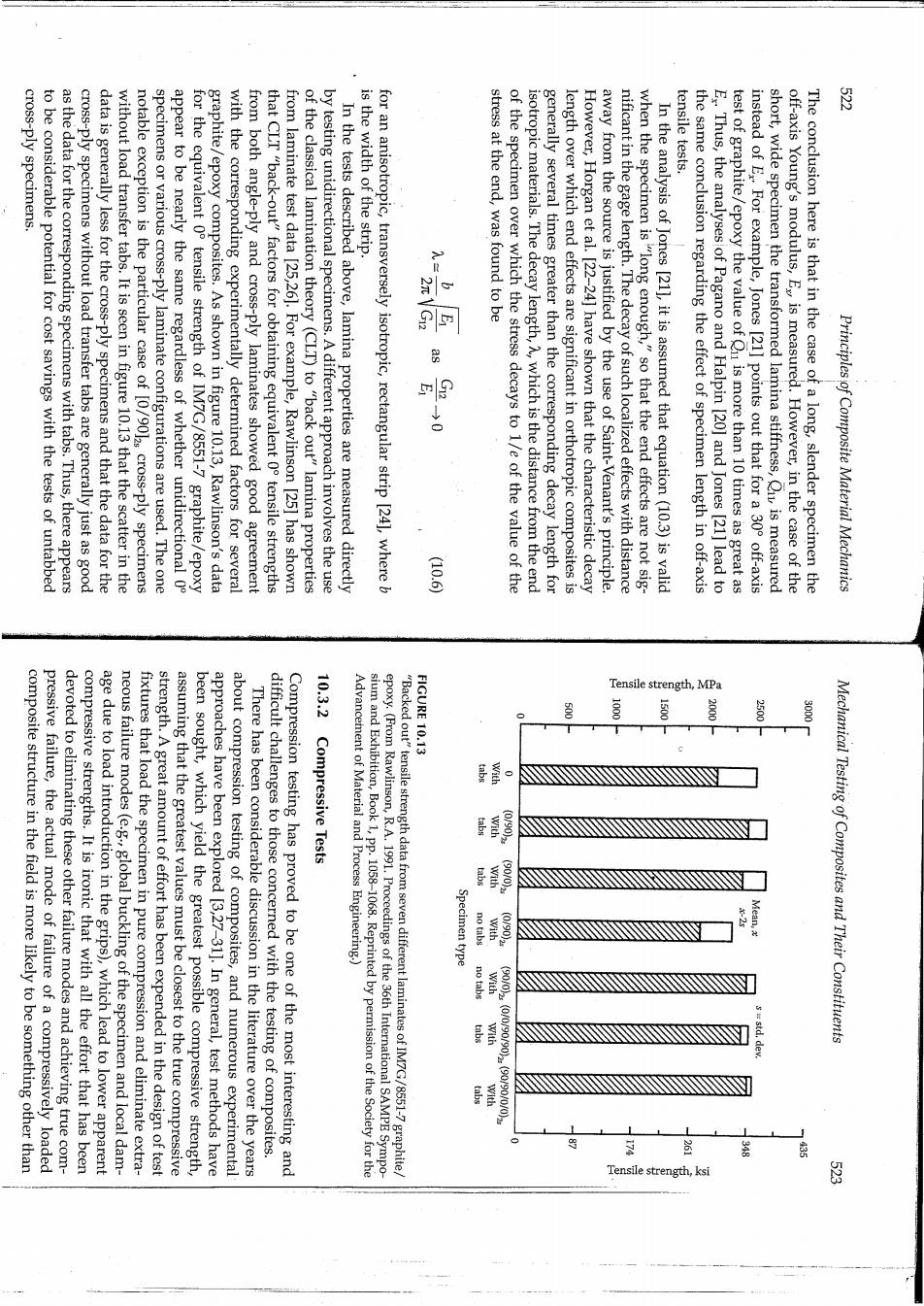

3 cross-ply specimens. tensile tests. to be considerable potential for cost savings with the tests of untabbed as the data for the corresponding specimens with tabs.Thus,there appears cross-ply specimens without load transfer tabs are generally just as good data is generally less for the cross-ply specimens and that the data for the without load transfer tabs.It is seen in figure 10.13 that the scatter in the notable exception is the particular case of [0/9012s cross-ply specimens specimens or various cross-ply laminate configurations are used.The one appear to be nearly the same regardless of whether unidirectional 0 for the equivalent 0 tensile strength of IM7G/8551-7 graphite/epoxy graphite/epoxy composites.As shown in figure 10.13,Rawlinson's data with the corresponding experimentally determined factors for several from both angle-ply and cross-ply laminates showed good agreement that CLT "back-out"factors for obtaining equivalent 0o tensile strengths from laminate test data [25,26].For example,Rawlinson [25]has shown of the classical lamination theory (CLT)to "back out"lamina properties by testing unidirectional specimens.A different approach involves the use In the tests described above,lamina properties are measured directly is the width of the strip. for an anisotropic,transversely isotropic,rectangular strip [24],where b stress at the end,was found to be as 出10 of the specimen over which the stress decays to 1/e of the value of the isotropic materials.The decay length,A,which is the distance from the end generally several times greater than the corresponding decay length for length over which end effects are significant in orthotropic composites is However,Horgan et al.[22-24]have shown that the characteristic decay away from the source is justified by the use of Saint-Venant's principle. nificant in the gage length.The decay of such localized effects with distance when the specimen is"long enough,"so that the end effects are not sig- In the analysis of Jones [21],it is assumed that equation(10.3)is valid the same conclusion regarding the effect of specimen length in off-axis E.Thus,the analyses of Pagano and Halpin [20]and Jones [21]lead to test of graphite/epoxy the value of Qu is more than 10 times as great as instead of E For example,Jones [21]points out that for a 30 off-axis short,wide specimen the transformed lamina stiffness,Qu is measured off-axis Young's modulus,E is measured.However,in the case of the The conclusion here is that in the case of a long,slender specimen the Principles of Composite Material Mechanics 10.6 10.3.2 Tensile strength,MPa FIGURE 10.13 50( 1000 3000 composite structure in the field is more likely to be something other than pressive failure,the actual mode of failure of a compressively loaded devoted to eliminating these other failure modes and achieving true com- compressive strengths.It is ironic that with all the effort that has been age due to load introduction in the grips),which lead to lower apparent neous failure modes(e.g global buckling of the specimen and local dam- fixtures that load the specimen in pure compression and eliminate extra- strength.A great amount of effort has been expended in the design of test assuming that the greatest values must be closest to the true compressive been sought,which yield the greatest possible compressive strength approaches have been explored [3,27-31].In general,test methods have about compression testing of composites,and numerous experimental difficult challenges to those concerned with the testing of composites. There has been considerable discussion in the literature over the years Compression testing has proved to be one of the most interesting and Compressive Tests Advancement of Material and Process Engineering.) epoxy.(From Rawlinson,R.A.1991.Proceedings of the 36th International SAMPE Sympo- sium and Exhibition,Book 1,pp.1058-1068.Reprinted by permission of the Society for the "Backed out"tensile strength data from seven different laminates of IM7G/8551-7graphite/ with Specimen type no tabs no tabs Mechanical Testing of Composites and Their Constituents Tensile strength,ksi