正在加载图片...

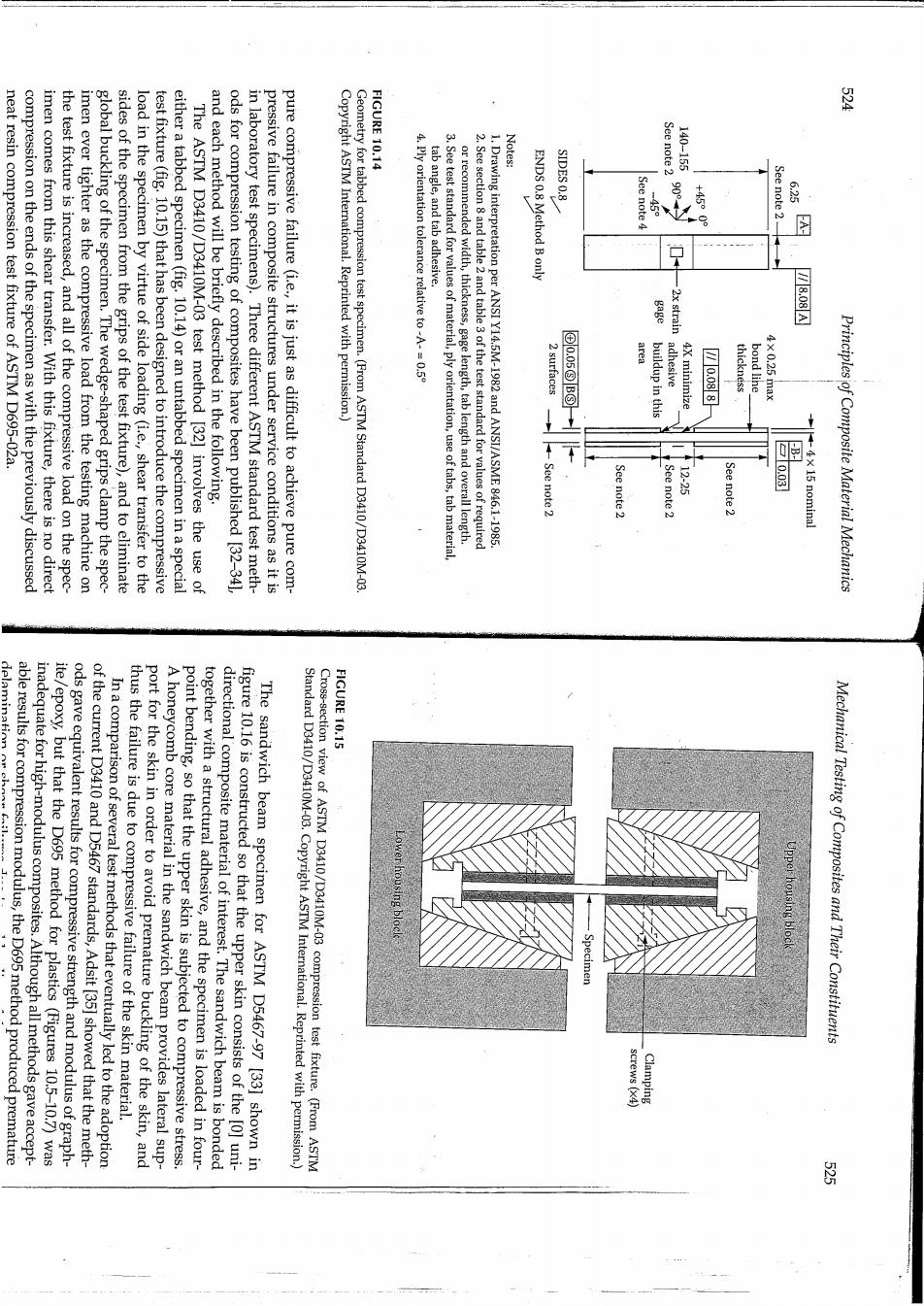

FIGURE 10.14 图 Notes: neat resin compression test fixture of ASTM D695-02a. See note 2 140-155 compression on the ends of the specimen as with the previously discussed imen comes from this shear transfer.With this fixture,there is no direct the test fixture is increased,and all of the compressive load on the spec- imen ever tighter as the compressive load from the testing machine on global buckling of the specimen.The wedge-shaped grips clamp the spec- sides of the specimen from the grips of the test fixture),and to eliminate load in the specimen by virtue of side loading (i.e.,shear transfer to the test fixture(fig.10.15)that has been designed to introduce the compressive either a tabbed specimen(fig.10.14)or an untabbed specimen in a special SIDES 0.8 The ASTM D3410/D3410M-03 test method [32]involves the use of and each method will be briefly described in the following. ods for compression testing of composites have been published [32-341 in laboratory test specimens).Three different ASTM standard test meth- pressive failure in composite structures under service conditions as it is pure compressive failure(i.e.,it is just as difficult to achieve pure com- Copyright ASTM International.Reprinted with permission.) Geometry for tabbed compression test specimen.(From ASTM Standard D3410/D3410M-03. 4.Ply orientation tolerance relative to-A-=0.5 tab angle,and tab adhesive. 3.See test standard for values of material,ply orientation,use of tabs,tab material, 2.See section 8 and table 2 and table3 of the test standard for values of required 1.Drawing interpretation per ANSI Y14.5M-1982 and ANSI/ASME 846.1-1985 ENDS 0.8 Method B only See note4 See note 2- 6.25 or recommended width,thickness,gage length,tab length and overall length. 图 2x strain 7808A 2surtaces G05888 area buildup in this adhesive 4X minimize thickness bond line X025max -See note 2 图 See note 2 See note 2 12-25 See note 2 -4x 15 nominal Principles of Composite Material Mechanics able results for compression modulus,the D695 method produced premature delamination or ch FIGURE 10.15 inadequate for high-modulus composites.Although all methods gave accept- ite/epoxy,but that the D695 method for plastics (Figures 10.5-10.7)was ods gave equivalent results for compressive strength and modulus of graph- of the current D3410 and D5467 standards,Adsit [35]showed that the meth- thus the failure is due to compressive failure of the skin material. In a comparison of several test methods that eventually led to the adoption port for the skin in order to avoid premature buckling of the skin,and point bending,so that the upper skin is subjected to compressive stress. A honeycomb core material in the sandwich beam provides lateral sup- together with a structural adhesive,and the specimen is loaded in four- directional composite material of interest.The sandwich beam is bonded figure 10.16 is constructed so that the upper skin consists of the [0]uni- The sandwich beam specimen for ASTM D5467-97 [33]shown in Standard D3410/D3410M-03.Copyright ASTM International.Reprinted with permission.) Cross-section view of ASTM D3410/D3410M-03 compression test fixture.(From ASTM housing bloc Mechanical Testing of Composites and Their Constituents crews (X4 Clamping 图