正在加载图片...

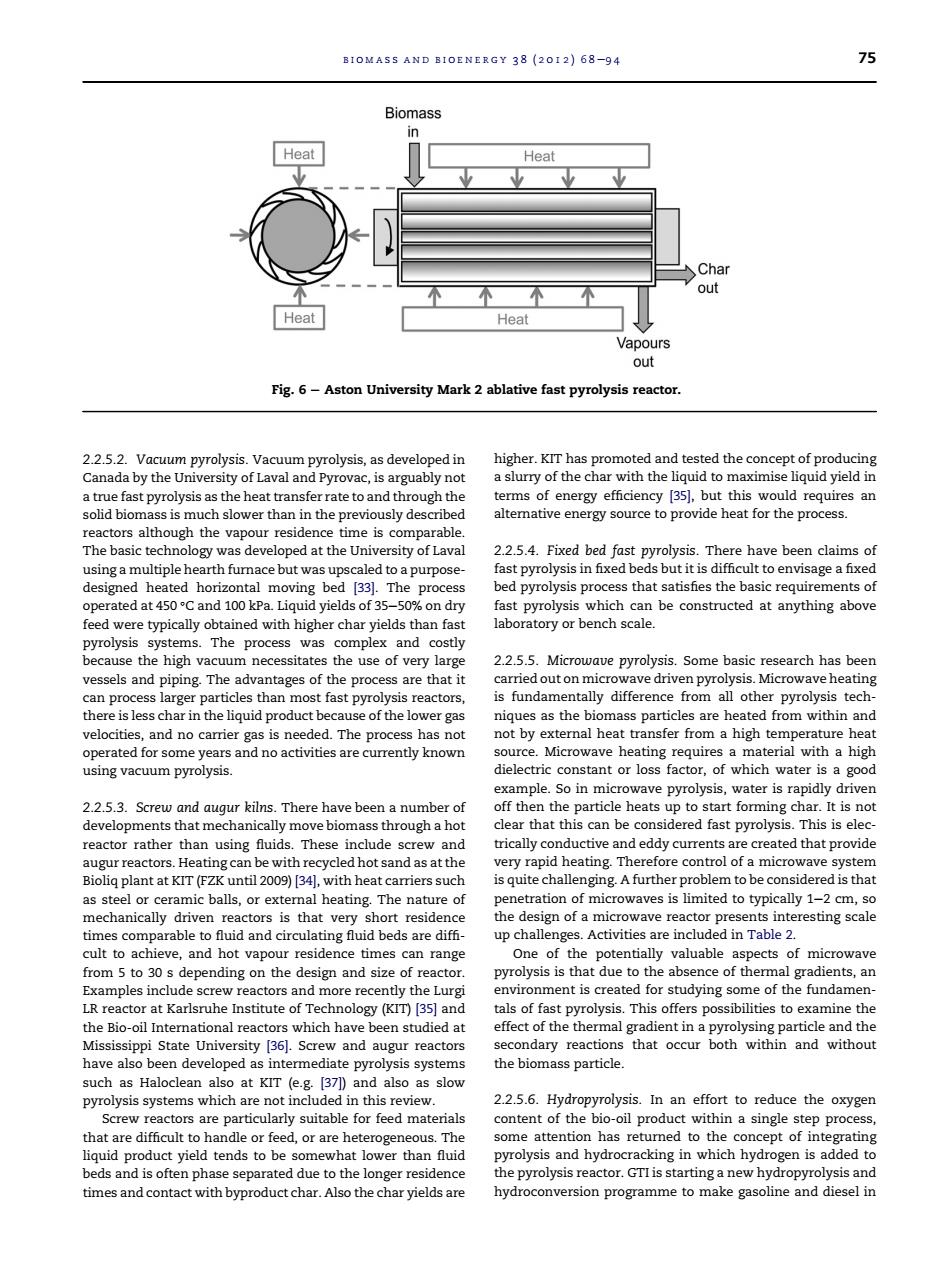

BIOMASS AND BIOENERGY 38 (2012)68-94 75 Biomass 方 ea Heat Char out Heat Heat Vapours out Fig.6-Aston University Mark 2 ablative fast pyrolysis reactor. 2.2.5.2.Vacuum pyrolysis.Vacuum pyrolysis,as developed in higher.KIT has promoted and tested the concept of producing Canada by the University of Laval and Pyrovac,is arguably not a slurry of the char with the liquid to maximise liquid yield in a true fast pyrolysis as the heat transfer rate to and through the terms of energy efficiency [35],but this would requires an solid biomass is much slower than in the previously described altemative energy source to provide heat for the process. reactors although the vapour residence time is comparable. The basic technology was developed at the University of Laval 2.2.5.4.Fixed bed fast pyrolysis.There have been claims of using a multiple hearth furace but was upscaled to a purpose- fast pyrolysis in fixed beds but it is difficult to envisage a fixed designed heated horizontal moving bed [33].The process bed pyrolysis process that satisfies the basic requirements of operated at 450C and 100 kPa.Liquid yields of 35-50%on dry fast pyrolysis which can be constructed at anything above feed were typically obtained with higher char yields than fast laboratory or bench scale pyrolysis systems.The process was complex and costly because the high vacuum necessitates the use of very large 2.2.5.5.Microwave pyrolysis.Some basic research has been vessels and piping.The advantages of the process are that it carried out on microwave driven pyrolysis.Microwave heating can process larger particles than most fast pyrolysis reactors, is fundamentally difference from all other pyrolysis tech- there is less char in the liquid product because of the lower gas niques as the biomass particles are heated from within and velocities,and no carrier gas is needed.The process has not not by external heat transfer from a high temperature heat operated for some years and no activities are currently known source.Microwave heating requires a material with a high using vacuum pyrolysis. dielectric constant or loss factor,of which water is a good example.So in microwave pyrolysis,water is rapidly driven 2.2.5.3.Screw and augur kilns.There have been a number of off then the particle heats up to start forming char.It is not developments that mechanically move biomass through a hot clear that this can be considered fast pyrolysis.This is elec- reactor rather than using fluids.These include screw and trically conductive and eddy currents are created that provide augur reactors.Heating can be with recycled hot sand as at the very rapid heating.Therefore control of a microwave system Biolig plant at KIT(FZK until 2009)[34],with heat carriers such is quite challenging.A further problem to be considered is that as steel or ceramic balls,or external heating.The nature of penetration of microwaves is limited to typically 1-2 cm,so mechanically driven reactors is that very short residence the design of a microwave reactor presents interesting scale times comparable to fluid and circulating fluid beds are diffi- up challenges.Activities are included in Table 2 cult to achieve,and hot vapour residence times can range One of the potentially valuable aspects of microwave from 5 to 30 s depending on the design and size of reactor. pyrolysis is that due to the absence of thermal gradients,an Examples include screw reactors and more recently the Lurgi environment is created for studying some of the fundamen- LR reactor at Karlsruhe Institute of Technology(KIT)[35]and tals of fast pyrolysis.This offers possibilities to examine the the Bio-oil International reactors which have been studied at effect of the thermal gradient in a pyrolysing particle and the Mississippi State University [36].Screw and augur reactors secondary reactions that occur both within and without have also been developed as intermediate pyrolysis systems the biomass particle. such as Haloclean also at KIT (e.g.[37))and also as slow pyrolysis systems which are not included in this review. 2.2.5.6.Hydropyrolysis.In an effort to reduce the oxygen Screw reactors are particularly suitable for feed materials content of the bio-oil product within a single step process, that are difficult to handle or feed,or are heterogeneous.The some attention has returned to the concept of integrating liquid product yield tends to be somewhat lower than fluid pyrolysis and hydrocracking in which hydrogen is added to beds and is often phase separated due to the longer residence the pyrolysis reactor.GTIis starting a new hydropyrolysis and times and contact with byproduct char.Also the char yields are hydroconversion programme to make gasoline and diesel in2.2.5.2. Vacuum pyrolysis. Vacuum pyrolysis, as developed in Canada by the University of Laval and Pyrovac, is arguably not a true fast pyrolysis as the heat transfer rate to and through the solid biomass is much slower than in the previously described reactors although the vapour residence time is comparable. The basic technology was developed at the University of Laval using a multiple hearth furnace but was upscaled to a purposedesigned heated horizontal moving bed [33]. The process operated at 450 C and 100 kPa. Liquid yields of 35e50% on dry feed were typically obtained with higher char yields than fast pyrolysis systems. The process was complex and costly because the high vacuum necessitates the use of very large vessels and piping. The advantages of the process are that it can process larger particles than most fast pyrolysis reactors, there is less char in the liquid product because of the lower gas velocities, and no carrier gas is needed. The process has not operated for some years and no activities are currently known using vacuum pyrolysis. 2.2.5.3. Screw and augur kilns. There have been a number of developments that mechanically move biomass through a hot reactor rather than using fluids. These include screw and augur reactors. Heating can be with recycled hot sand as at the Bioliq plant at KIT (FZK until 2009) [34], with heat carriers such as steel or ceramic balls, or external heating. The nature of mechanically driven reactors is that very short residence times comparable to fluid and circulating fluid beds are diffi- cult to achieve, and hot vapour residence times can range from 5 to 30 s depending on the design and size of reactor. Examples include screw reactors and more recently the Lurgi LR reactor at Karlsruhe Institute of Technology (KIT) [35] and the Bio-oil International reactors which have been studied at Mississippi State University [36]. Screw and augur reactors have also been developed as intermediate pyrolysis systems such as Haloclean also at KIT (e.g. [37]) and also as slow pyrolysis systems which are not included in this review. Screw reactors are particularly suitable for feed materials that are difficult to handle or feed, or are heterogeneous. The liquid product yield tends to be somewhat lower than fluid beds and is often phase separated due to the longer residence times and contact with byproduct char. Also the char yields are higher. KIT has promoted and tested the concept of producing a slurry of the char with the liquid to maximise liquid yield in terms of energy efficiency [35], but this would requires an alternative energy source to provide heat for the process. 2.2.5.4. Fixed bed fast pyrolysis. There have been claims of fast pyrolysis in fixed beds but it is difficult to envisage a fixed bed pyrolysis process that satisfies the basic requirements of fast pyrolysis which can be constructed at anything above laboratory or bench scale. 2.2.5.5. Microwave pyrolysis. Some basic research has been carried out on microwave driven pyrolysis. Microwave heating is fundamentally difference from all other pyrolysis techniques as the biomass particles are heated from within and not by external heat transfer from a high temperature heat source. Microwave heating requires a material with a high dielectric constant or loss factor, of which water is a good example. So in microwave pyrolysis, water is rapidly driven off then the particle heats up to start forming char. It is not clear that this can be considered fast pyrolysis. This is electrically conductive and eddy currents are created that provide very rapid heating. Therefore control of a microwave system is quite challenging. A further problem to be considered is that penetration of microwaves is limited to typically 1e2 cm, so the design of a microwave reactor presents interesting scale up challenges. Activities are included in Table 2. One of the potentially valuable aspects of microwave pyrolysis is that due to the absence of thermal gradients, an environment is created for studying some of the fundamentals of fast pyrolysis. This offers possibilities to examine the effect of the thermal gradient in a pyrolysing particle and the secondary reactions that occur both within and without the biomass particle. 2.2.5.6. Hydropyrolysis. In an effort to reduce the oxygen content of the bio-oil product within a single step process, some attention has returned to the concept of integrating pyrolysis and hydrocracking in which hydrogen is added to the pyrolysis reactor. GTI is starting a new hydropyrolysis and hydroconversion programme to make gasoline and diesel in Fig. 6 e Aston University Mark 2 ablative fast pyrolysis reactor. biomass and bioenergy 38 (2012) 68 e9 4 75