正在加载图片...

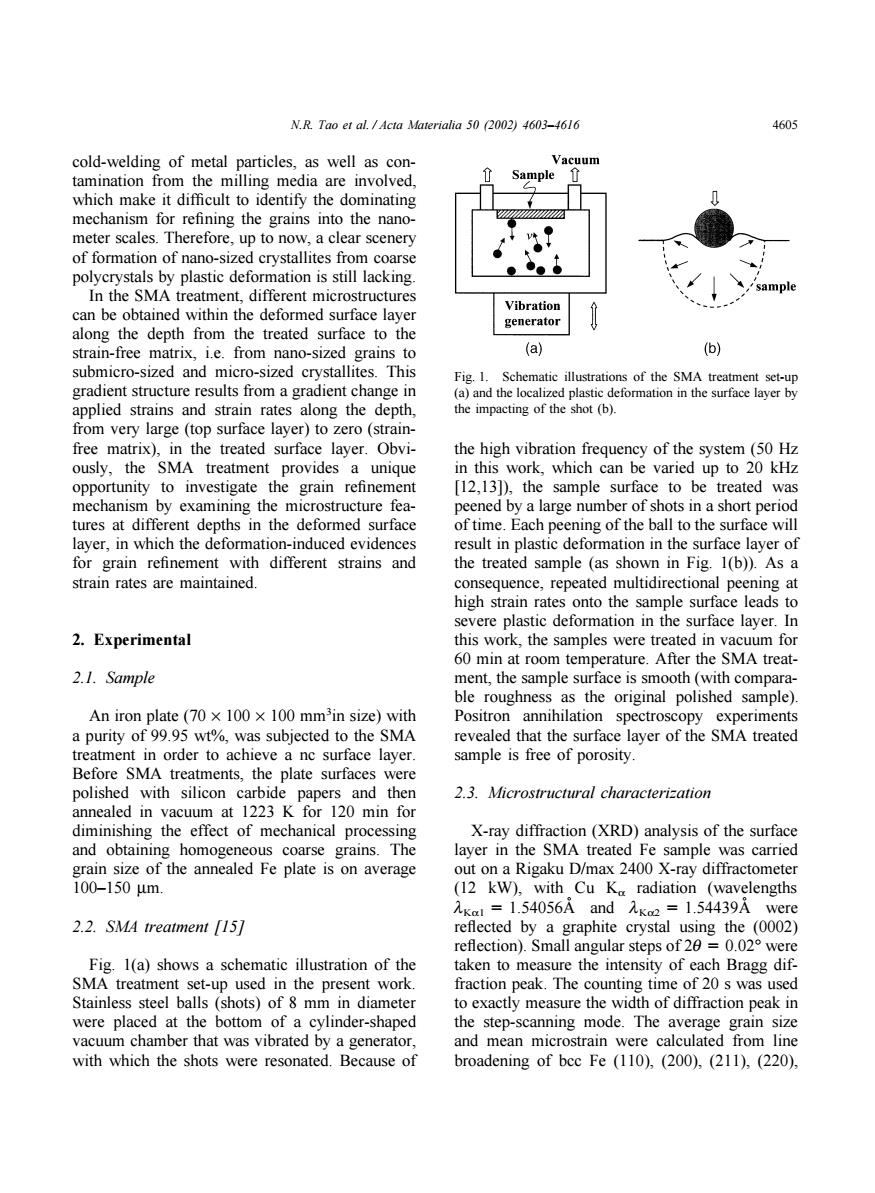

N.R.Tao et al.Acta Materialia 50 (2002)4603-4616 4605 cold-welding of metal particles,as well as con- Vacuum tamination from the milling media are involved, Sample which make it difficult to identify the dominating mechanism for refining the grains into the nano- meter scales.Therefore,up to now,a clear scenery of formation of nano-sized crystallites from coarse polycrystals by plastic deformation is still lacking. In the SMA treatment,different microstructures Vibration can be obtained within the deformed surface layer generator along the depth from the treated surface to the strain-free matrix,i.e.from nano-sized grains to (a) (b) submicro-sized and micro-sized crystallites.This Fig.1. Schematic illustrations of the SMA treatment set-up gradient structure results from a gradient change in (a)and the localized plastic deformation in the surface layer by applied strains and strain rates along the depth, the impacting of the shot (b). from very large (top surface layer)to zero(strain- free matrix),in the treated surface layer.Obvi- the high vibration frequency of the system(50 Hz ously,the SMA treatment provides a unique in this work,which can be varied up to 20 kHz opportunity to investigate the grain refinement [12,131),the sample surface to be treated was mechanism by examining the microstructure fea- peened by a large number of shots in a short period tures at different depths in the deformed surface of time.Each peening of the ball to the surface will layer,in which the deformation-induced evidences result in plastic deformation in the surface layer of for grain refinement with different strains and the treated sample (as shown in Fig.1(b)).As a strain rates are maintained. consequence,repeated multidirectional peening at high strain rates onto the sample surface leads to severe plastic deformation in the surface layer.In 2.Experimental this work,the samples were treated in vacuum for 60 min at room temperature.After the SMA treat- 2.1.Sample ment,the sample surface is smooth (with compara- ble roughness as the original polished sample) An iron plate(70×l00×l00mm3 in size)with Positron annihilation spectroscopy experiments a purity of 99.95 wt%,was subjected to the SMA revealed that the surface layer of the SMA treated treatment in order to achieve a nc surface layer. sample is free of porosity. Before SMA treatments,the plate surfaces were polished with silicon carbide papers and then 2.3.Microstructural characterization annealed in vacuum at 1223 K for 120 min for diminishing the effect of mechanical processing X-ray diffraction (XRD)analysis of the surface and obtaining homogeneous coarse grains.The layer in the SMA treated Fe sample was carried grain size of the annealed Fe plate is on average out on a Rigaku D/max 2400 X-ray diffractometer 100-150um (12 kW),with Cu Ko radiation (wavelengths AKa 1.54056A and AKo2 1.54439A were 2.2.SMA treatment [15] reflected by a graphite crystal using the (0002) reflection).Small angular steps of 20 =0.02 were Fig.1(a)shows a schematic illustration of the taken to measure the intensity of each Bragg dif- SMA treatment set-up used in the present work. fraction peak.The counting time of 20 s was used Stainless steel balls (shots)of 8 mm in diameter to exactly measure the width of diffraction peak in were placed at the bottom of a cylinder-shaped the step-scanning mode.The average grain size vacuum chamber that was vibrated by a generator, and mean microstrain were calculated from line with which the shots were resonated.Because of broadening of bcc Fe (110),(200),(211),(220),N.R. Tao et al. / Acta Materialia 50 (2002) 4603–4616 4605 cold-welding of metal particles, as well as contamination from the milling media are involved, which make it difficult to identify the dominating mechanism for refining the grains into the nanometer scales. Therefore, up to now, a clear scenery of formation of nano-sized crystallites from coarse polycrystals by plastic deformation is still lacking. In the SMA treatment, different microstructures can be obtained within the deformed surface layer along the depth from the treated surface to the strain-free matrix, i.e. from nano-sized grains to submicro-sized and micro-sized crystallites. This gradient structure results from a gradient change in applied strains and strain rates along the depth, from very large (top surface layer) to zero (strainfree matrix), in the treated surface layer. Obviously, the SMA treatment provides a unique opportunity to investigate the grain refinement mechanism by examining the microstructure features at different depths in the deformed surface layer, in which the deformation-induced evidences for grain refinement with different strains and strain rates are maintained. 2. Experimental 2.1. Sample An iron plate (70 × 100 × 100 mm3 in size) with a purity of 99.95 wt%, was subjected to the SMA treatment in order to achieve a nc surface layer. Before SMA treatments, the plate surfaces were polished with silicon carbide papers and then annealed in vacuum at 1223 K for 120 min for diminishing the effect of mechanical processing and obtaining homogeneous coarse grains. The grain size of the annealed Fe plate is on average 100–150 µm. 2.2. SMA treatment [15] Fig. 1(a) shows a schematic illustration of the SMA treatment set-up used in the present work. Stainless steel balls (shots) of 8 mm in diameter were placed at the bottom of a cylinder-shaped vacuum chamber that was vibrated by a generator, with which the shots were resonated. Because of Fig. 1. Schematic illustrations of the SMA treatment set-up (a) and the localized plastic deformation in the surface layer by the impacting of the shot (b). the high vibration frequency of the system (50 Hz in this work, which can be varied up to 20 kHz [12,13]), the sample surface to be treated was peened by a large number of shots in a short period of time. Each peening of the ball to the surface will result in plastic deformation in the surface layer of the treated sample (as shown in Fig. 1(b)). As a consequence, repeated multidirectional peening at high strain rates onto the sample surface leads to severe plastic deformation in the surface layer. In this work, the samples were treated in vacuum for 60 min at room temperature. After the SMA treatment, the sample surface is smooth (with comparable roughness as the original polished sample). Positron annihilation spectroscopy experiments revealed that the surface layer of the SMA treated sample is free of porosity. 2.3. Microstructural characterization X-ray diffraction (XRD) analysis of the surface layer in the SMA treated Fe sample was carried out on a Rigaku D/max 2400 X-ray diffractometer (12 kW), with Cu Kα radiation (wavelengths lKα1 1.54056A˚ and lKα2 1.54439A˚ were reflected by a graphite crystal using the (0002) reflection). Small angular steps of 2q 0.02° were taken to measure the intensity of each Bragg diffraction peak. The counting time of 20 s was used to exactly measure the width of diffraction peak in the step-scanning mode. The average grain size and mean microstrain were calculated from line broadening of bcc Fe (110), (200), (211), (220)