正在加载图片...

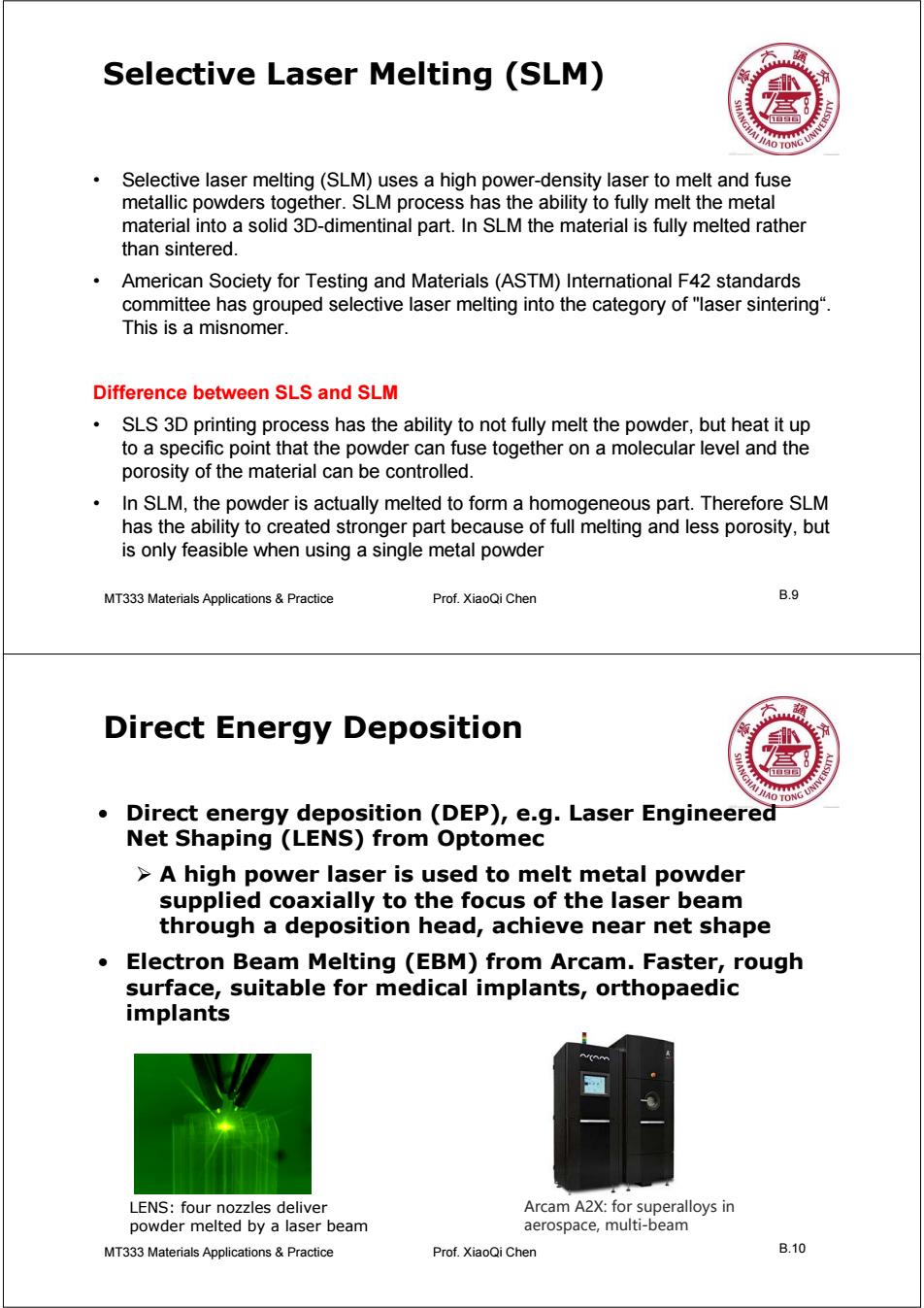

Selective Laser Melting (SLM) MAO TONG Selective laser melting(SLM)uses a high power-density laser to melt and fuse metallic powders together.SLM process has the ability to fully melt the metal material into a solid 3D-dimentinal part.In SLM the material is fully melted rather than sintered. American Society for Testing and Materials (ASTM)International F42 standards committee has grouped selective laser melting into the category of"laser sintering". This is a misnomer. Difference between SLS and SLM SLS 3D printing process has the ability to not fully melt the powder,but heat it up to a specific point that the powder can fuse together on a molecular level and the porosity of the material can be controlled. In SLM,the powder is actually melted to form a homogeneous part.Therefore SLM has the ability to created stronger part because of full melting and less porosity,but is only feasible when using a single metal powder MT333 Materials Applications Practice Prof.XiaoQi Chen B.9 Direct Energy Deposition AO TONG U ● Direct energy deposition(DEP),e.g.Laser Engineered Net Shaping (LENS)from Optomec >A high power laser is used to melt metal powder supplied coaxially to the focus of the laser beam through a deposition head,achieve near net shape Electron Beam Melting (EBM)from Arcam.Faster,rough surface,suitable for medical implants,orthopaedic implants LENS:four nozzles deliver Arcam A2X:for superalloys in powder melted by a laser beam aerospace,multi-beam MT333 Materials Applications&Practice Prof.XiaoQi Chen B.10MT333 Materials Applications B.9 & Practice Prof. XiaoQi Chen Selective Laser Melting (SLM) • Selective laser melting (SLM) uses a high power-density laser to melt and fuse metallic powders together. SLM process has the ability to fully melt the metal material into a solid 3D-dimentinal part. In SLM the material is fully melted rather than sintered. • American Society for Testing and Materials (ASTM) International F42 standards committee has grouped selective laser melting into the category of "laser sintering“. This is a misnomer. Difference between SLS and SLM • SLS 3D printing process has the ability to not fully melt the powder, but heat it up to a specific point that the powder can fuse together on a molecular level and the porosity of the material can be controlled. • In SLM, the powder is actually melted to form a homogeneous part. Therefore SLM has the ability to created stronger part because of full melting and less porosity, but is only feasible when using a single metal powder MT333 Materials Applications B.10 & Practice Prof. XiaoQi Chen • Direct energy deposition (DEP), e.g. Laser Engineered Net Shaping (LENS) from Optomec A high power laser is used to melt metal powder supplied coaxially to the focus of the laser beam through a deposition head, achieve near net shape • Electron Beam Melting (EBM) from Arcam. Faster, rough surface, suitable for medical implants, orthopaedic implants Direct Energy Deposition LENS: four nozzles deliver powder melted by a laser beam Arcam A2X: for superalloys in aerospace, multi-beam