正在加载图片...

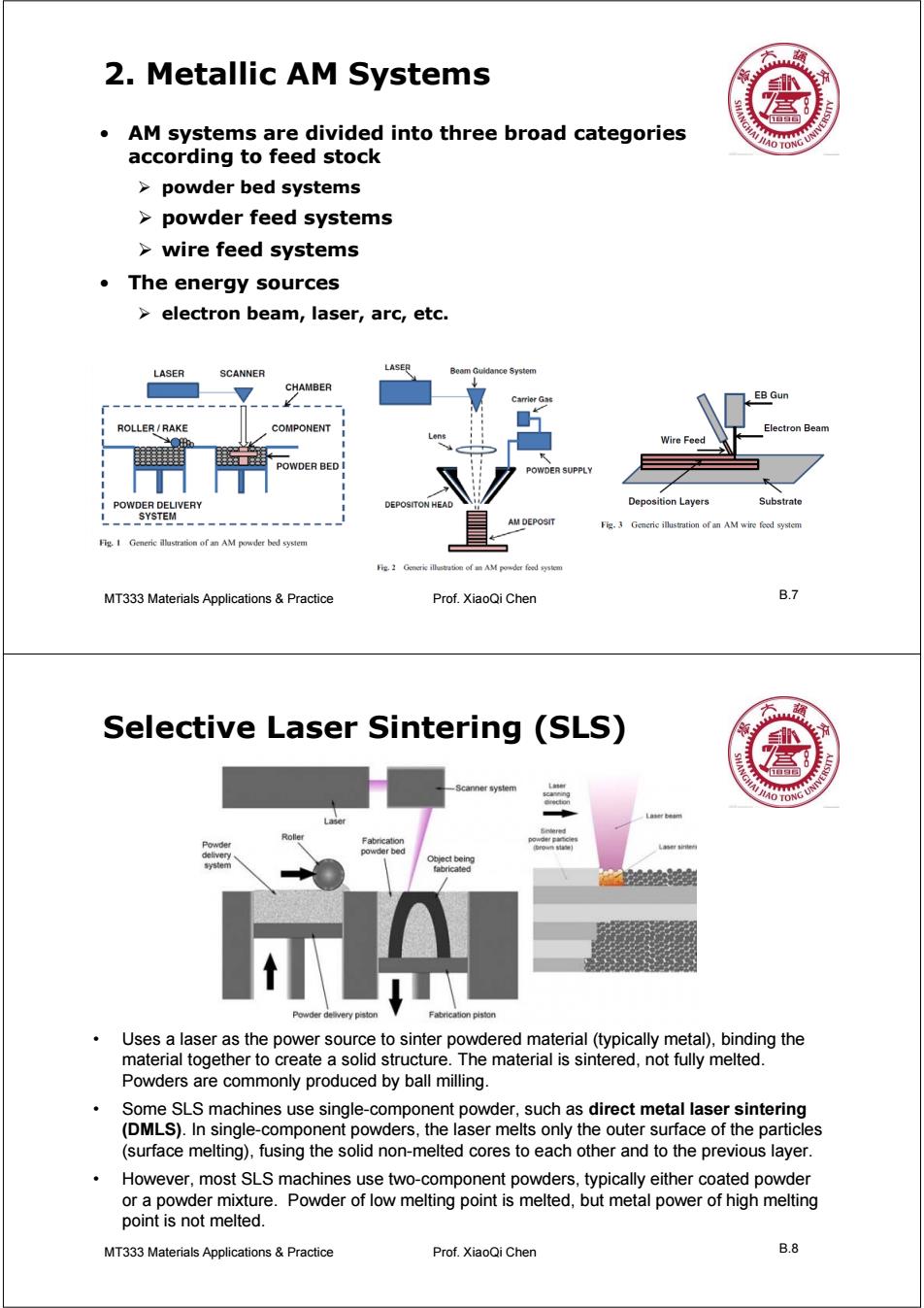

2.Metallic AM Systems AM systems are divided into three broad categories HAO TO ONG UN according to feed stock >powder bed systems powder feed systems >wire feed systems ●The energy sources >electron beam,laser,arc,etc. LASER SCANNER LASER Beam Guidance System CHAMBER EB Gur ROLLER/RAKE COMPONENT Electron Beam Wire Feed ■ POWDER BED I POWDER SUPPLY POWDER DELIVERY Deposition Layers Substrate L-SYSTEM AM DEPOSIT Fig.3 Generic illuistmution of an AM wire feed system Fig 1 Generic illustration of an AM powder bed system Fig.2 Generic illtion of AM powder foed system MT333 Materials Applications Practice Prof.XiaoQi Chen B.7 Selective Laser Sintering (SLS) O TONG UN Fabrication powder bed Powder delivery piston Uses a laser as the power source to sinter powdered material(typically metal),binding the material together to create a solid structure.The material is sintered,not fully melted. Powders are commonly produced by ball milling. Some SLS machines use single-component powder,such as direct metal laser sintering (DMLS).In single-component powders,the laser melts only the outer surface of the particles (surface melting),fusing the solid non-melted cores to each other and to the previous layer. However,most SLS machines use two-component powders,typically either coated powder or a powder mixture.Powder of low melting point is melted,but metal power of high melting point is not melted. MT333 Materials Applications&Practice Prof.XiaoQi Chen B.8MT333 Materials Applications B.7 & Practice Prof. XiaoQi Chen 2. Metallic AM Systems • AM systems are divided into three broad categories according to feed stock powder bed systems powder feed systems wire feed systems • The energy sources electron beam, laser, arc, etc. MT333 Materials Applications B.8 & Practice Prof. XiaoQi Chen Selective Laser Sintering (SLS) • Uses a laser as the power source to sinter powdered material (typically metal), binding the material together to create a solid structure. The material is sintered, not fully melted. Powders are commonly produced by ball milling. • Some SLS machines use single-component powder, such as direct metal laser sintering (DMLS). In single-component powders, the laser melts only the outer surface of the particles (surface melting), fusing the solid non-melted cores to each other and to the previous layer. • However, most SLS machines use two-component powders, typically either coated powder or a powder mixture. Powder of low melting point is melted, but metal power of high melting point is not melted