正在加载图片...

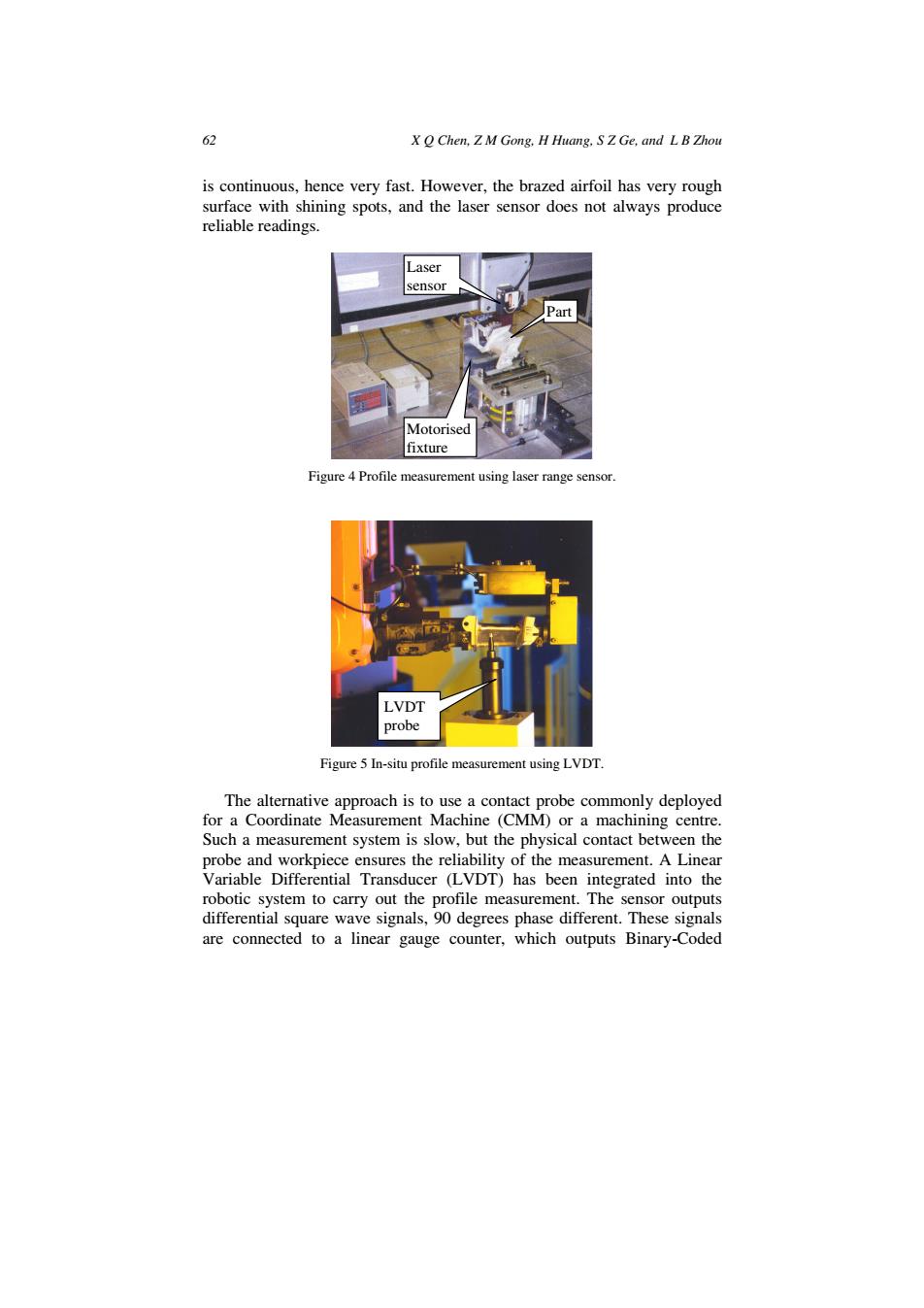

62 X O Chen,Z M Gong,H Huang,S Z Ge,and L B Zhou is continuous,hence very fast.However,the brazed airfoil has very rough surface with shining spots,and the laser sensor does not always produce reliable readings. Laser sensor Part Motorised fixture Figure 4 Profile measurement using laser range sensor LVDT probe Figure 5 In-situ profile measurement using LVDT. The alternative approach is to use a contact probe commonly deployed for a Coordinate Measurement Machine (CMM)or a machining centre. Such a measurement system is slow,but the physical contact between the probe and workpiece ensures the reliability of the measurement.A Linear Variable Differential Transducer (LVDT)has been integrated into the robotic system to carry out the profile measurement.The sensor outputs differential square wave signals,90 degrees phase different.These signals are connected to a linear gauge counter,which outputs Binary-Coded62 X Q Chen, Z M Gong, H Huang, S Z Ge, and L B Zhou is continuous, hence very fast. However, the brazed airfoil has very rough surface with shining spots, and the laser sensor does not always produce reliable readings. Figure 4 Profile measurement using laser range sensor. Figure 5 In-situ profile measurement using LVDT. The alternative approach is to use a contact probe commonly deployed for a Coordinate Measurement Machine (CMM) or a machining centre. Such a measurement system is slow, but the physical contact between the probe and workpiece ensures the reliability of the measurement. A Linear Variable Differential Transducer (LVDT) has been integrated into the robotic system to carry out the profile measurement. The sensor outputs differential square wave signals, 90 degrees phase different. These signals are connected to a linear gauge counter, which outputs Binary-Coded Laser sensor Part Motorised fixture LVDT probe