正在加载图片...

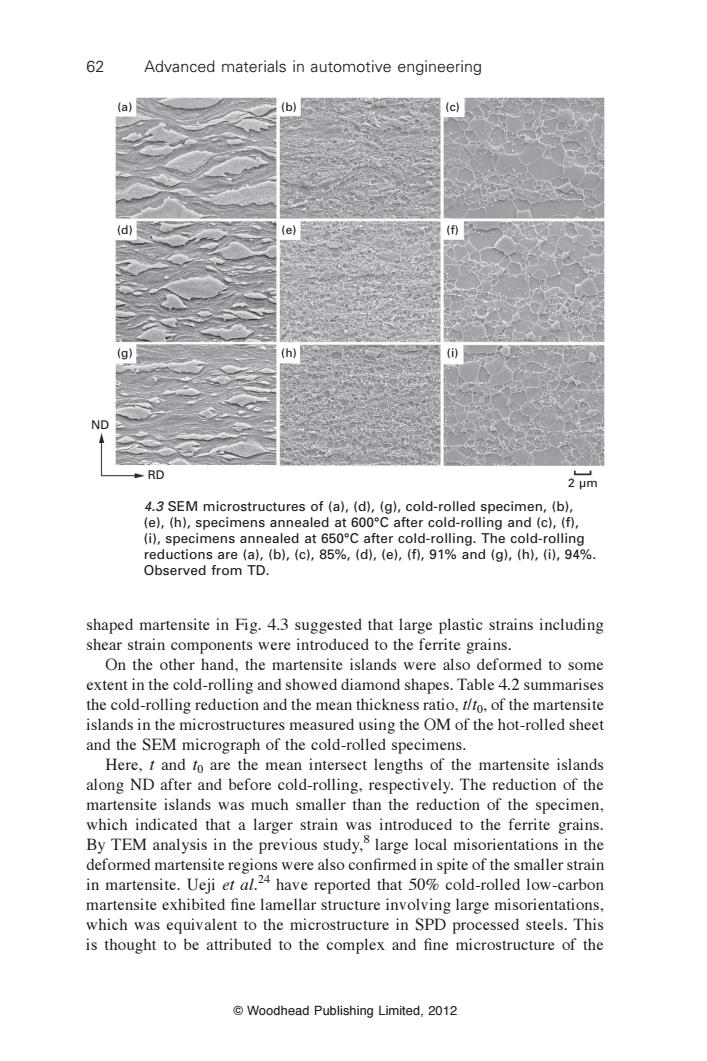

62 Advanced materials in automotive engineering (b) c (d) (e) (f) (g (h) () ND RD 2μm 4.3 SEM microstructures of (a),(d),(g),cold-rolled specimen,(b), (e),(h),specimens annealed at 600C after cold-rolling and (c),(f), (i),specimens annealed at 650C after cold-rolling.The cold-rolling reductions are (a),(b),(c),85%,(d),(e),(f),91%and (g),(h),(i),94%. Observed from TD. shaped martensite in Fig.4.3 suggested that large plastic strains including shear strain components were introduced to the ferrite grains. On the other hand,the martensite islands were also deformed to some extent in the cold-rolling and showed diamond shapes.Table 4.2 summarises the cold-rolling reduction and the mean thickness ratio,t/to,of the martensite islands in the microstructures measured using the OM of the hot-rolled sheet and the SEM micrograph of the cold-rolled specimens. Here,t and to are the mean intersect lengths of the martensite islands along ND after and before cold-rolling,respectively.The reduction of the martensite islands was much smaller than the reduction of the specimen, which indicated that a larger strain was introduced to the ferrite grains. By TEM analysis in the previous study,s large local misorientations in the deformed martensite regions were also confirmed in spite of the smaller strain in martensite.Ueji et al.24 have reported that 50%cold-rolled low-carbon martensite exhibited fine lamellar structure involving large misorientations. which was equivalent to the microstructure in SPD processed steels.This is thought to be attributed to the complex and fine microstructure of the Woodhead Publishing Limited,201262 Advanced materials in automotive engineering © Woodhead Publishing Limited, 2012 shaped martensite in Fig. 4.3 suggested that large plastic strains including shear strain components were introduced to the ferrite grains. On the other hand, the martensite islands were also deformed to some extent in the cold-rolling and showed diamond shapes. Table 4.2 summarises the cold-rolling reduction and the mean thickness ratio, t/t0, of the martensite islands in the microstructures measured using the OM of the hot-rolled sheet and the SEM micrograph of the cold-rolled specimens. Here, t and t0 are the mean intersect lengths of the martensite islands along ND after and before cold-rolling, respectively. The reduction of the martensite islands was much smaller than the reduction of the specimen, which indicated that a larger strain was introduced to the ferrite grains. By TEM analysis in the previous study,8 large local misorientations in the deformed martensite regions were also confirmed in spite of the smaller strain in martensite. Ueji et al. 24 have reported that 50% cold-rolled low-carbon martensite exhibited fine lamellar structure involving large misorientations, which was equivalent to the microstructure in SPD processed steels. This is thought to be attributed to the complex and fine microstructure of the (a) (d) (g) (b) (e) (h) (c) (f) (i) ND RD 2 µm 4.3 SEM microstructures of (a), (d), (g), cold-rolled specimen, (b), (e), (h), specimens annealed at 600°C after cold-rolling and (c), (f), (i), specimens annealed at 650°C after cold-rolling. The cold-rolling reductions are (a), (b), (c), 85%, (d), (e), (f), 91% and (g), (h), (i), 94%. Observed from TD