正在加载图片...

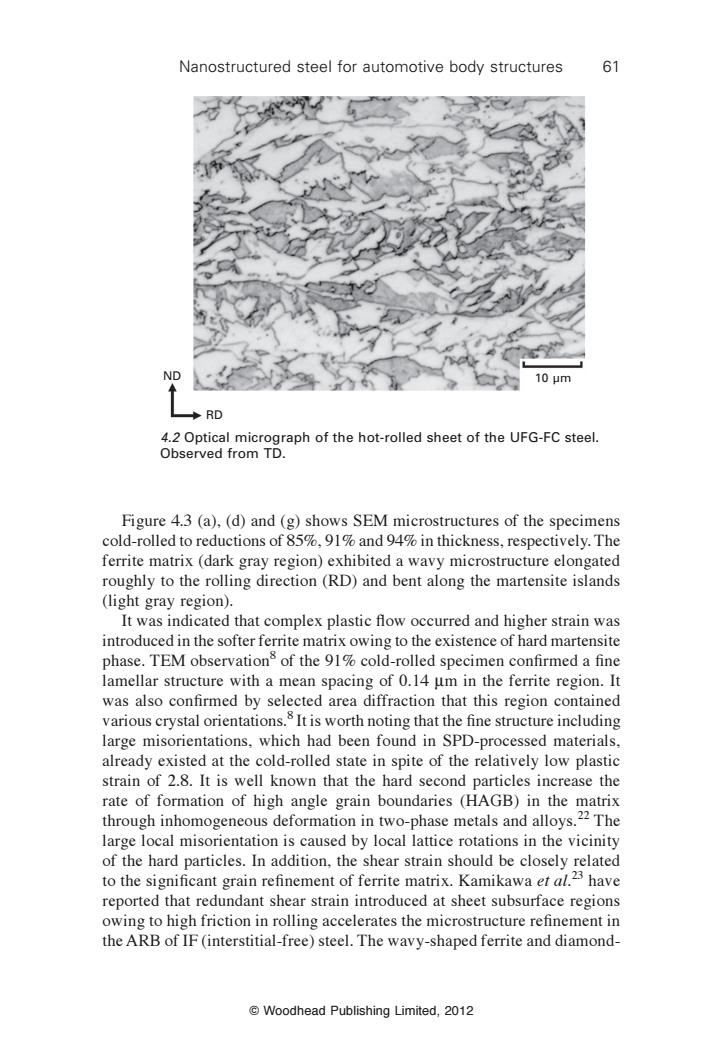

Nanostructured steel for automotive body structures 61 ND 10μm RD 4.2 Optical micrograph of the hot-rolled sheet of the UFG-FC steel. Observed from TD. Figure 4.3 (a),(d)and(g)shows SEM microstructures of the specimens cold-rolled to reductions of 85%,91%and 94%in thickness,respectively.The ferrite matrix(dark gray region)exhibited a wavy microstructure elongated roughly to the rolling direction(RD)and bent along the martensite islands (light gray region). It was indicated that complex plastic flow occurred and higher strain was introduced in the softer ferrite matrix owing to the existence of hard martensite phase.TEM observation"of the 91%cold-rolled specimen confirmed a fine lamellar structure with a mean spacing of 0.14 um in the ferrite region.It was also confirmed by selected area diffraction that this region contained various crystal orientations.It is worth noting that the fine structure including large misorientations,which had been found in SPD-processed materials, already existed at the cold-rolled state in spite of the relatively low plastic strain of 2.8.It is well known that the hard second particles increase the rate of formation of high angle grain boundaries (HAGB)in the matrix through inhomogeneous deformation in two-phase metals and alloys.22 The large local misorientation is caused by local lattice rotations in the vicinity of the hard particles.In addition,the shear strain should be closely related to the significant grain refinement of ferrite matrix.Kamikawa et al.3 have reported that redundant shear strain introduced at sheet subsurface regions owing to high friction in rolling accelerates the microstructure refinement in the ARB of IF(interstitial-free)steel.The wavy-shaped ferrite and diamond- Woodhead Publishing Limited,2012Nanostructured steel for automotive body structures 61 © Woodhead Publishing Limited, 2012 Figure 4.3 (a), (d) and (g) shows SEM microstructures of the specimens cold-rolled to reductions of 85%, 91% and 94% in thickness, respectively. The ferrite matrix (dark gray region) exhibited a wavy microstructure elongated roughly to the rolling direction (RD) and bent along the martensite islands (light gray region). It was indicated that complex plastic flow occurred and higher strain was introduced in the softer ferrite matrix owing to the existence of hard martensite phase. TEM observation8 of the 91% cold-rolled specimen confirmed a fine lamellar structure with a mean spacing of 0.14 mm in the ferrite region. It was also confirmed by selected area diffraction that this region contained various crystal orientations.8 It is worth noting that the fine structure including large misorientations, which had been found in SPD-processed materials, already existed at the cold-rolled state in spite of the relatively low plastic strain of 2.8. It is well known that the hard second particles increase the rate of formation of high angle grain boundaries (HAGB) in the matrix through inhomogeneous deformation in two-phase metals and alloys.22 The large local misorientation is caused by local lattice rotations in the vicinity of the hard particles. In addition, the shear strain should be closely related to the significant grain refinement of ferrite matrix. Kamikawa et al. 23 have reported that redundant shear strain introduced at sheet subsurface regions owing to high friction in rolling accelerates the microstructure refinement in the ARB of IF (interstitial-free) steel. The wavy-shaped ferrite and diamondND RD 10 µm 4.2 Optical micrograph of the hot-rolled sheet of the UFG-FC steel. Observed from TD