正在加载图片...

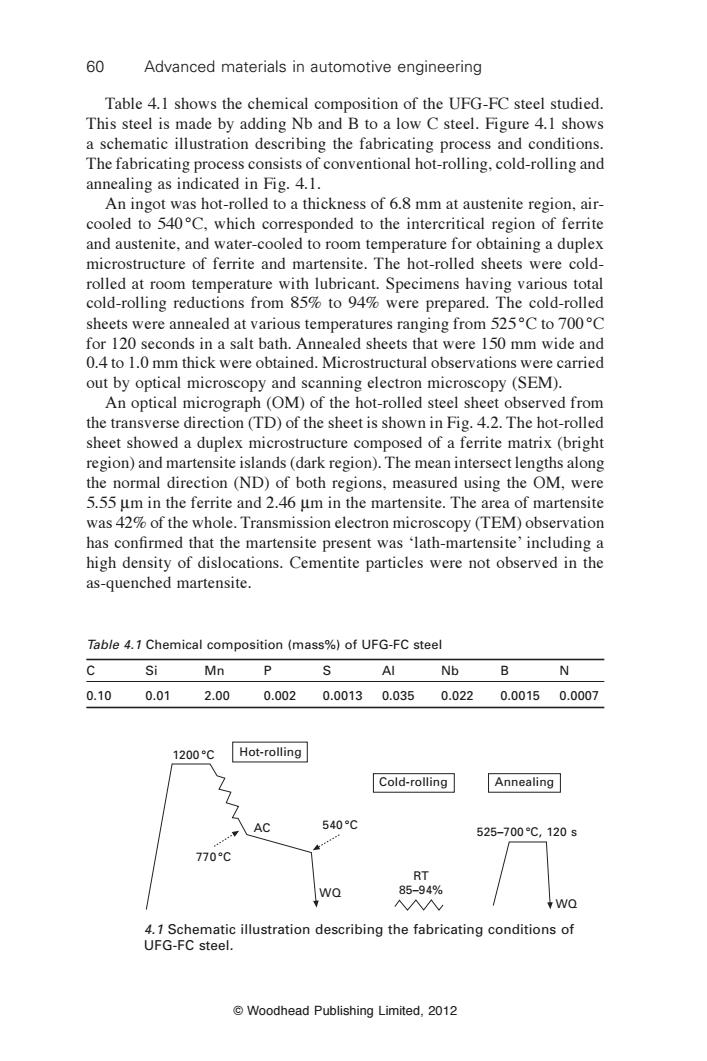

60 Advanced materials in automotive engineering Table 4.1 shows the chemical composition of the UFG-FC steel studied. This steel is made by adding Nb and B to a low C steel.Figure 4.1 shows a schematic illustration describing the fabricating process and conditions. The fabricating process consists of conventional hot-rolling,cold-rolling and annealing as indicated in Fig.4.1. An ingot was hot-rolled to a thickness of 6.8 mm at austenite region,air- cooled to 540C,which corresponded to the intercritical region of ferrite and austenite,and water-cooled to room temperature for obtaining a duplex microstructure of ferrite and martensite.The hot-rolled sheets were cold- rolled at room temperature with lubricant.Specimens having various total cold-rolling reductions from 85%to 94%were prepared.The cold-rolled sheets were annealed at various temperatures ranging from 525C to 700C for 120 seconds in a salt bath.Annealed sheets that were 150 mm wide and 0.4 to 1.0 mm thick were obtained.Microstructural observations were carried out by optical microscopy and scanning electron microscopy (SEM). An optical micrograph(OM)of the hot-rolled steel sheet observed from the transverse direction (TD)of the sheet is shown in Fig.4.2.The hot-rolled sheet showed a duplex microstructure composed of a ferrite matrix(bright region)and martensite islands(dark region).The mean intersect lengths along the normal direction (ND)of both regions,measured using the OM,were 5.55 um in the ferrite and 2.46 um in the martensite.The area of martensite was 42%of the whole.Transmission electron microscopy (TEM)observation has confirmed that the martensite present was 'lath-martensite'including a high density of dislocations.Cementite particles were not observed in the as-quenched martensite. Table 4.1 Chemical composition (mass%)of UFG-FC steel C Si Mn P S Al Nb B N 0.10 0.01 2.00 0.002 0.00130.035 0.0220.00150.0007 1200C Hot-rolling Cold-rolling Annealing AC 540°C 525-700C,120s 770°C RT 85-94% 入v Wo 4.1 Schematic illustration describing the fabricating conditions of UFG-FC steel. Woodhead Publishing Limited,201260 Advanced materials in automotive engineering © Woodhead Publishing Limited, 2012 Table 4.1 shows the chemical composition of the UFG-FC steel studied. This steel is made by adding Nb and B to a low C steel. Figure 4.1 shows a schematic illustration describing the fabricating process and conditions. The fabricating process consists of conventional hot-rolling, cold-rolling and annealing as indicated in Fig. 4.1. An ingot was hot-rolled to a thickness of 6.8 mm at austenite region, aircooled to 540 °C, which corresponded to the intercritical region of ferrite and austenite, and water-cooled to room temperature for obtaining a duplex microstructure of ferrite and martensite. The hot-rolled sheets were coldrolled at room temperature with lubricant. Specimens having various total cold-rolling reductions from 85% to 94% were prepared. The cold-rolled sheets were annealed at various temperatures ranging from 525 °C to 700 °C for 120 seconds in a salt bath. Annealed sheets that were 150 mm wide and 0.4 to 1.0 mm thick were obtained. Microstructural observations were carried out by optical microscopy and scanning electron microscopy (SEM). An optical micrograph (OM) of the hot-rolled steel sheet observed from the transverse direction (TD) of the sheet is shown in Fig. 4.2. The hot-rolled sheet showed a duplex microstructure composed of a ferrite matrix (bright region) and martensite islands (dark region). The mean intersect lengths along the normal direction (ND) of both regions, measured using the OM, were 5.55 mm in the ferrite and 2.46 mm in the martensite. The area of martensite was 42% of the whole. Transmission electron microscopy (TEM) observation has confirmed that the martensite present was ‘lath-martensite’ including a high density of dislocations. Cementite particles were not observed in the as-quenched martensite. Table 4.1 Chemical composition (mass%) of UFG-FC steel C Si Mn P S Al Nb B N 0.10 0.01 2.00 0.002 0.0013 0.035 0.022 0.0015 0.0007 1200 °C Hot-rolling Cold-rolling Annealing 770 °C AC WQ WQ 540 °C RT 85–94% 525–700 °C, 120 s 4.1 Schematic illustration describing the fabricating conditions of UFG-FC steel