正在加载图片...

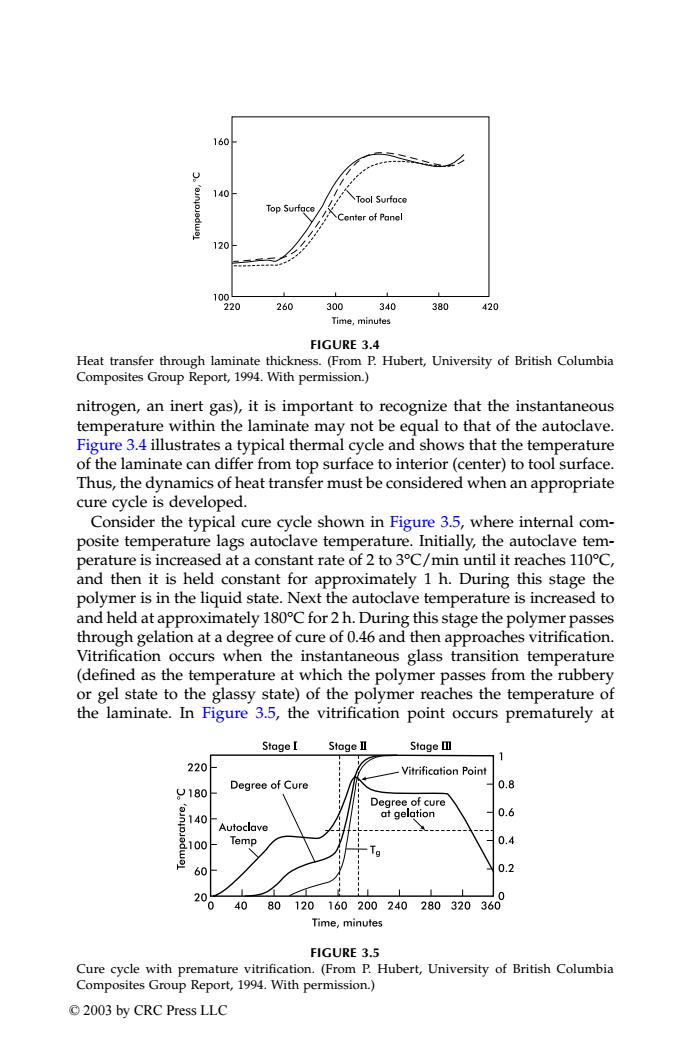

160 140 Tool Surface Top Surface Center of Panel 120 100 220 260 300340 380 420 Time,minutes FIGURE 3.4 Heat transfer through laminate thickness.(From P.Hubert,University of British Columbia Composites Group Report,1994.With permission.) nitrogen,an inert gas),it is important to recognize that the instantaneous temperature within the laminate may not be equal to that of the autoclave Figure 3.4 illustrates a typical thermal cycle and shows that the temperature of the laminate can differ from top surface to interior(center)to tool surface. Thus,the dynamics of heat transfer must be considered when an appropriate cure cycle is developed. Consider the typical cure cycle shown in Figure 3.5,where internal com- posite temperature lags autoclave temperature.Initially,the autoclave tem- perature is increased at a constant rate of 2 to 3C/min until it reaches 110C, and then it is held constant for approximately 1 h.During this stage the polymer is in the liquid state.Next the autoclave temperature is increased to and held at approximately 180C for 2 h.During this stage the polymer passes through gelation at a degree of cure of 0.46 and then approaches vitrification. Vitrification occurs when the instantaneous glass transition temperature (defined as the temperature at which the polymer passes from the rubbery or gel state to the glassy state)of the polymer reaches the temperature of the laminate.In Figure 3.5,the vitrification point occurs prematurely at Stage I StageⅡ StageⅢ 220 Vitrification Point 0.8 V180 Degree of Cure Degree of cure at gelation 0.6 Autoclave Temp 0.4 60 0.2 2 04080120160200240280320360 Time,minutes FIGURE 3.5 Cure cycle with premature vitrification.(From P.Hubert,University of British Columbia Composites Group Report,1994.With permission.) 2003 by CRC Press LLCnitrogen, an inert gas), it is important to recognize that the instantaneous temperature within the laminate may not be equal to that of the autoclave. Figure 3.4 illustrates a typical thermal cycle and shows that the temperature of the laminate can differ from top surface to interior (center) to tool surface. Thus, the dynamics of heat transfer must be considered when an appropriate cure cycle is developed. Consider the typical cure cycle shown in Figure 3.5, where internal composite temperature lags autoclave temperature. Initially, the autoclave temperature is increased at a constant rate of 2 to 3°C/min until it reaches 110°C, and then it is held constant for approximately 1 h. During this stage the polymer is in the liquid state. Next the autoclave temperature is increased to and held at approximately 180°C for 2 h. During this stage the polymer passes through gelation at a degree of cure of 0.46 and then approaches vitrification. Vitrification occurs when the instantaneous glass transition temperature (defined as the temperature at which the polymer passes from the rubbery or gel state to the glassy state) of the polymer reaches the temperature of the laminate. In Figure 3.5, the vitrification point occurs prematurely at FIGURE 3.4 Heat transfer through laminate thickness. (From P. Hubert, University of British Columbia Composites Group Report, 1994. With permission.) FIGURE 3.5 Cure cycle with premature vitrification. (From P. Hubert, University of British Columbia Composites Group Report, 1994. With permission.) TX001_ch03_Frame Page 40 Saturday, September 21, 2002 4:51 AM © 2003 by CRC Press LLC