正在加载图片...

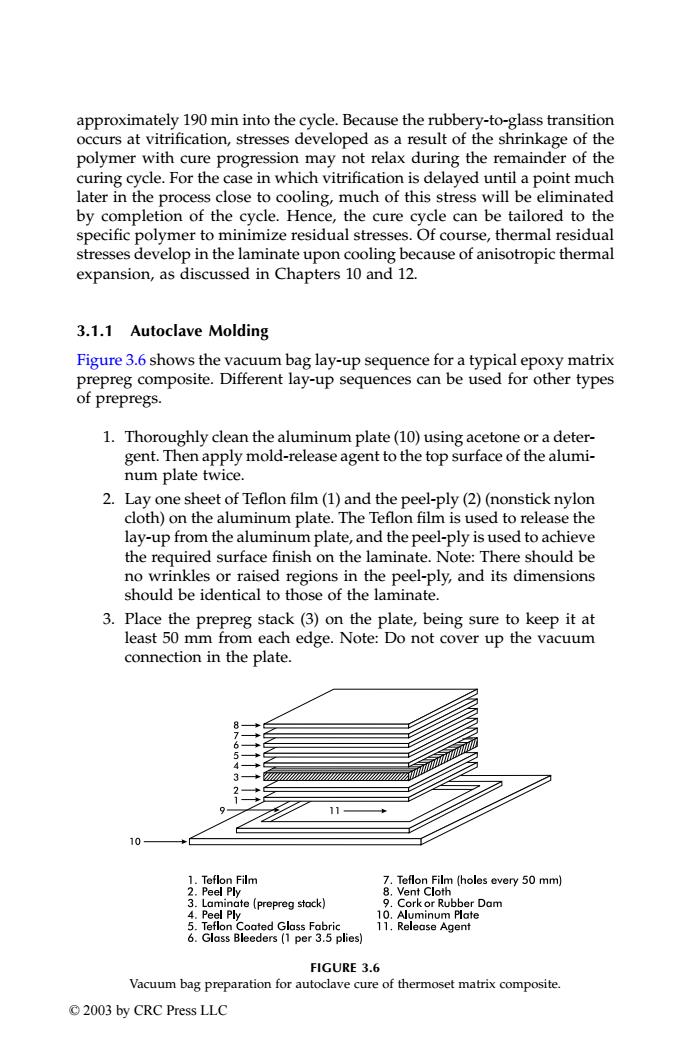

approximately 190 min into the cycle.Because the rubbery-to-glass transition occurs at vitrification,stresses developed as a result of the shrinkage of the polymer with cure progression may not relax during the remainder of the curing cycle.For the case in which vitrification is delayed until a point much later in the process close to cooling,much of this stress will be eliminated by completion of the cycle.Hence,the cure cycle can be tailored to the specific polymer to minimize residual stresses.Of course,thermal residual stresses develop in the laminate upon cooling because of anisotropic thermal expansion,as discussed in Chapters 10 and 12. 3.1.1 Autoclave Molding Figure 3.6 shows the vacuum bag lay-up sequence for a typical epoxy matrix prepreg composite.Different lay-up sequences can be used for other types of prepregs. 1.Thoroughly clean the aluminum plate(10)using acetone or a deter- gent.Then apply mold-release agent to the top surface of the alumi- num plate twice. 2.Lay one sheet of Teflon film(1)and the peel-ply(2)(nonstick nylon cloth)on the aluminum plate.The Teflon film is used to release the lay-up from the aluminum plate,and the peel-ply is used to achieve the required surface finish on the laminate.Note:There should be no wrinkles or raised regions in the peel-ply,and its dimensions should be identical to those of the laminate. 3.Place the prepreg stack(3)on the plate,being sure to keep it at least 50 mm from each edge.Note:Do not cover up the vacuum connection in the plate. 10 1.Teflon Film 7.Teflon Film (holes every 50 mm) 2.Peel Ply 8.Vent Cloth 3.Laminate (prepreg stack) 9.Corkor Rubber Dam 4.Peel Ply 10.Aluminum Plate 5.Teflon Coated Glass Fabric 11.Release Agent 6.Glass Bleeders(1 per 3.5 plies) FIGURE 3.6 Vacuum bag preparation for autoclave cure of thermoset matrix composite. ©2003 by CRC Press LLCapproximately 190 min into the cycle. Because the rubbery-to-glass transition occurs at vitrification, stresses developed as a result of the shrinkage of the polymer with cure progression may not relax during the remainder of the curing cycle. For the case in which vitrification is delayed until a point much later in the process close to cooling, much of this stress will be eliminated by completion of the cycle. Hence, the cure cycle can be tailored to the specific polymer to minimize residual stresses. Of course, thermal residual stresses develop in the laminate upon cooling because of anisotropic thermal expansion, as discussed in Chapters 10 and 12. 3.1.1 Autoclave Molding Figure 3.6 shows the vacuum bag lay-up sequence for a typical epoxy matrix prepreg composite. Different lay-up sequences can be used for other types of prepregs. 1. Thoroughly clean the aluminum plate (10) using acetone or a detergent. Then apply mold-release agent to the top surface of the aluminum plate twice. 2. Lay one sheet of Teflon film (1) and the peel-ply (2) (nonstick nylon cloth) on the aluminum plate. The Teflon film is used to release the lay-up from the aluminum plate, and the peel-ply is used to achieve the required surface finish on the laminate. Note: There should be no wrinkles or raised regions in the peel-ply, and its dimensions should be identical to those of the laminate. 3. Place the prepreg stack (3) on the plate, being sure to keep it at least 50 mm from each edge. Note: Do not cover up the vacuum connection in the plate. FIGURE 3.6 Vacuum bag preparation for autoclave cure of thermoset matrix composite. TX001_ch03_Frame Page 41 Saturday, September 21, 2002 4:51 AM © 2003 by CRC Press LLC