正在加载图片...

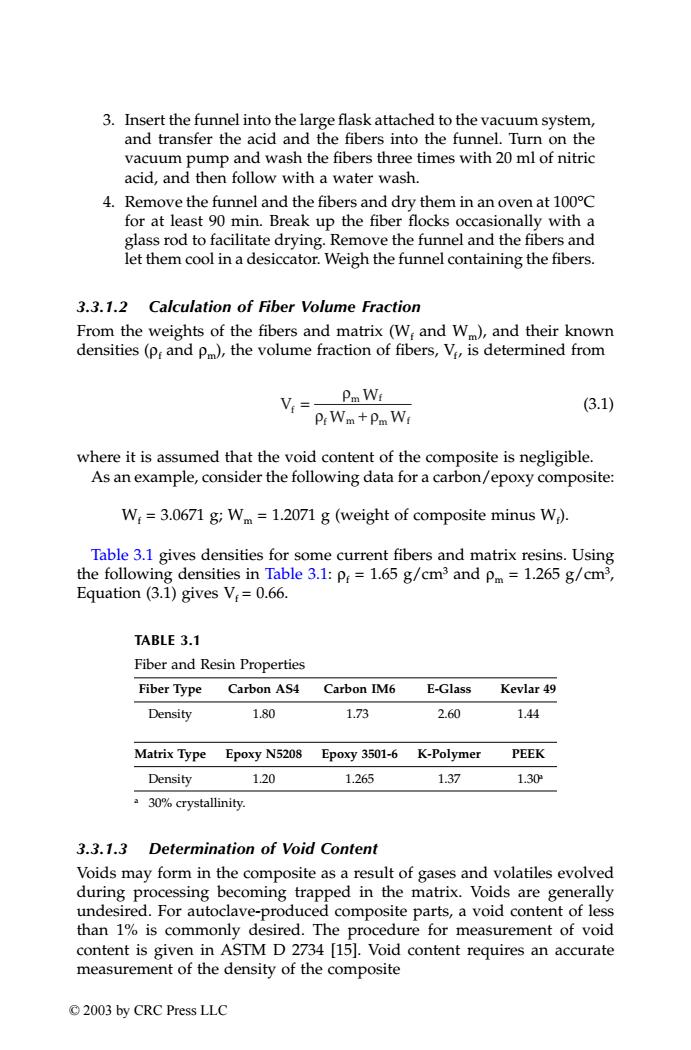

3.Insert the funnel into the large flask attached to the vacuum system, and transfer the acid and the fibers into the funnel.Turn on the vacuum pump and wash the fibers three times with 20 ml of nitric acid,and then follow with a water wash. 4.Remove the funnel and the fibers and dry them in an oven at 100C for at least 90 min.Break up the fiber flocks occasionally with a glass rod to facilitate drying.Remove the funnel and the fibers and let them cool in a desiccator.Weigh the funnel containing the fibers. 3.3.1.2 Calculation of Fiber Volume Fraction From the weights of the fibers and matrix (W:and Wm),and their known densities (p,and pm),the volume fraction of fibers,Vi,is determined from Vi=Pm Wr (3.1) P:Wm+Pm Wr where it is assumed that the void content of the composite is negligible As an example,consider the following data for a carbon/epoxy composite: W:=3.0671 g;Wm=1.2071 g(weight of composite minus W ) Table 3.1 gives densities for some current fibers and matrix resins.Using the following densities in Table 3.1:P=1.65 g/cm3 and Pm=1.265 g/cm3, Equation (3.1)gives V:=0.66. TABLE 3.1 Fiber and Resin Properties Fiber Type Carbon AS4 Carbon IM6 E-Glass Kevlar 49 Density 1.80 1.73 2.60 1.44 Matrix Type Epoxy N5208 Epoxy 3501-6 K-Polymer PEEK Density 1.20 1.265 1.37 1.30 30%crystallinity. 3.3.1.3 Determination of Void Content Voids may form in the composite as a result of gases and volatiles evolved during processing becoming trapped in the matrix.Voids are generally undesired.For autoclave-produced composite parts,a void content of less than 1%is commonly desired.The procedure for measurement of void content is given in ASTM D 2734 [15].Void content requires an accurate measurement of the density of the composite 2003 by CRC Press LLC3. Insert the funnel into the large flask attached to the vacuum system, and transfer the acid and the fibers into the funnel. Turn on the vacuum pump and wash the fibers three times with 20 ml of nitric acid, and then follow with a water wash. 4. Remove the funnel and the fibers and dry them in an oven at 100°C for at least 90 min. Break up the fiber flocks occasionally with a glass rod to facilitate drying. Remove the funnel and the fibers and let them cool in a desiccator. Weigh the funnel containing the fibers. 3.3.1.2 Calculation of Fiber Volume Fraction From the weights of the fibers and matrix (Wf and Wm), and their known densities (ρf and ρm), the volume fraction of fibers, Vf, is determined from (3.1) where it is assumed that the void content of the composite is negligible. As an example, consider the following data for a carbon/epoxy composite: Wf = 3.0671 g; Wm = 1.2071 g (weight of composite minus Wf ). Table 3.1 gives densities for some current fibers and matrix resins. Using the following densities in Table 3.1: ρf = 1.65 g/cm3 and ρm = 1.265 g/cm3, Equation (3.1) gives Vf = 0.66. 3.3.1.3 Determination of Void Content Voids may form in the composite as a result of gases and volatiles evolved during processing becoming trapped in the matrix. Voids are generally undesired. For autoclave-produced composite parts, a void content of less than 1% is commonly desired. The procedure for measurement of void content is given in ASTM D 2734 [15]. Void content requires an accurate measurement of the density of the composite TABLE 3.1 Fiber and Resin Properties Fiber Type Carbon AS4 Carbon IM6 E-Glass Kevlar 49 Density 1.80 1.73 2.60 1.44 Matrix Type Epoxy N5208 Epoxy 3501-6 K-Polymer PEEK Density 1.20 1.265 1.37 1.30a a 30% crystallinity. V W W W f m f f m m f = + ρ ρ ρ TX001_ch03_Frame Page 51 Saturday, September 21, 2002 4:51 AM © 2003 by CRC Press LLC