正在加载图片...

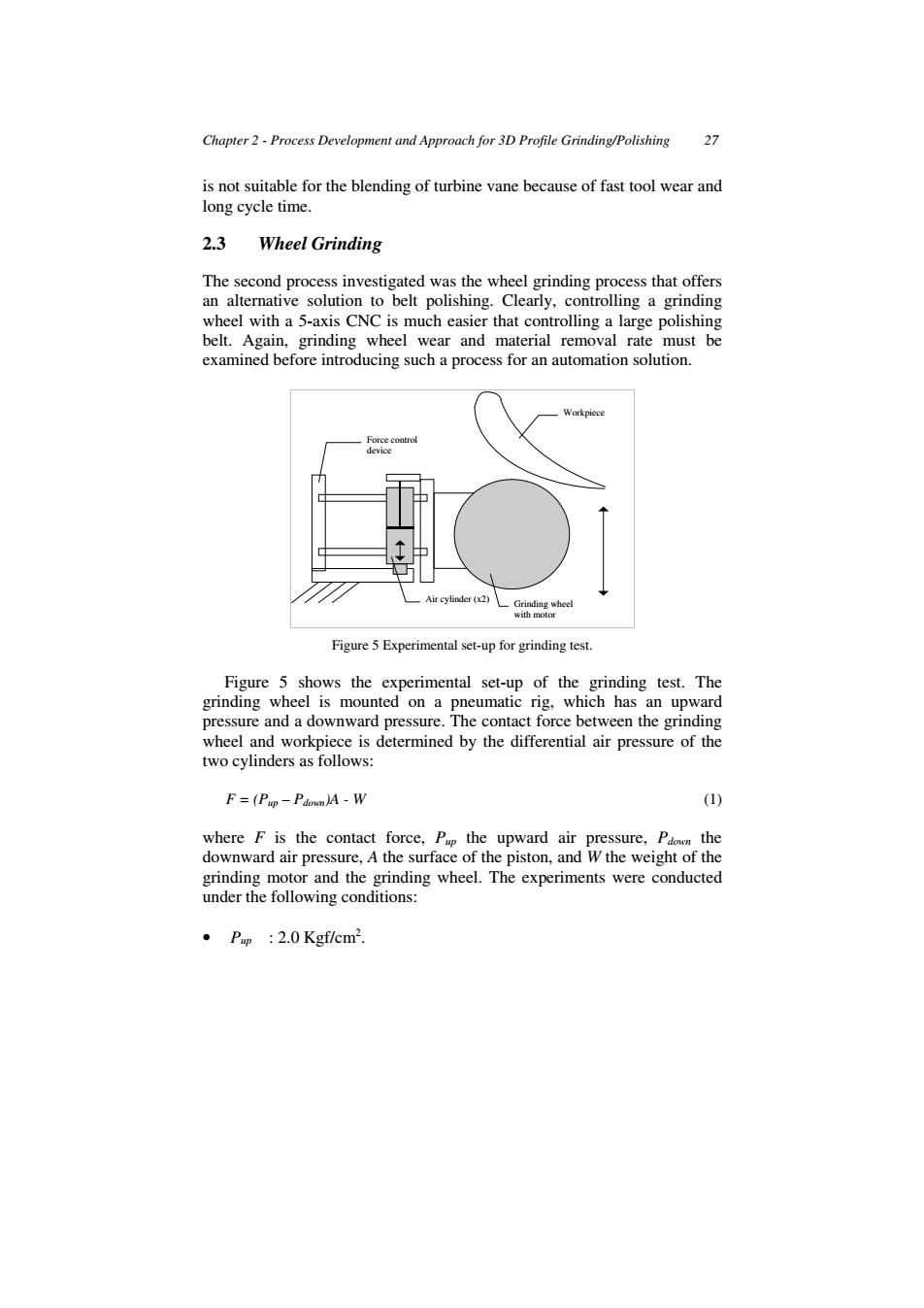

Chapter 2-Process Development and Approach for 3D Profile Grinding/Polishing 27 is not suitable for the blending of turbine vane because of fast tool wear and long cycle time. 2.3 Wheel Grinding The second process investigated was the wheel grinding process that offers an alternative solution to belt polishing.Clearly,controlling a grinding wheel with a 5-axis CNC is much easier that controlling a large polishing belt.Again,grinding wheel wear and material removal rate must be examined before introducing such a process for an automation solution. Air cylinder(2)) Grinding wheel with motor Figure 5 Experimental set-up for grinding test Figure 5 shows the experimental set-up of the grinding test.The grinding wheel is mounted on a pneumatic rig,which has an upward pressure and a downward pressure.The contact force between the grinding wheel and workpiece is determined by the differential air pressure of the two cylinders as follows: F=(Pup-Pdoun)A-W (1) where F is the contact force,Pup the upward air pressure,Pdowm the downward air pressure,A the surface of the piston,and W the weight of the grinding motor and the grinding wheel.The experiments were conducted under the following conditions: 。Pp:2.0 Kgf/cm2.Chapter 2 - Process Development and Approach for 3D Profile Grinding/Polishing 27 is not suitable for the blending of turbine vane because of fast tool wear and long cycle time. 2.3 Wheel Grinding The second process investigated was the wheel grinding process that offers an alternative solution to belt polishing. Clearly, controlling a grinding wheel with a 5-axis CNC is much easier that controlling a large polishing belt. Again, grinding wheel wear and material removal rate must be examined before introducing such a process for an automation solution. Workpiece Force control device Air cylinder (x2) Grinding wheel with motor Figure 5 Experimental set-up for grinding test. Figure 5 shows the experimental set-up of the grinding test. The grinding wheel is mounted on a pneumatic rig, which has an upward pressure and a downward pressure. The contact force between the grinding wheel and workpiece is determined by the differential air pressure of the two cylinders as follows: F = (Pup – Pdown)A - W (1) where F is the contact force, Pup the upward air pressure, Pdown the downward air pressure, A the surface of the piston, and W the weight of the grinding motor and the grinding wheel. The experiments were conducted under the following conditions: • Pup : 2.0 Kgf/cm2