正在加载图片...

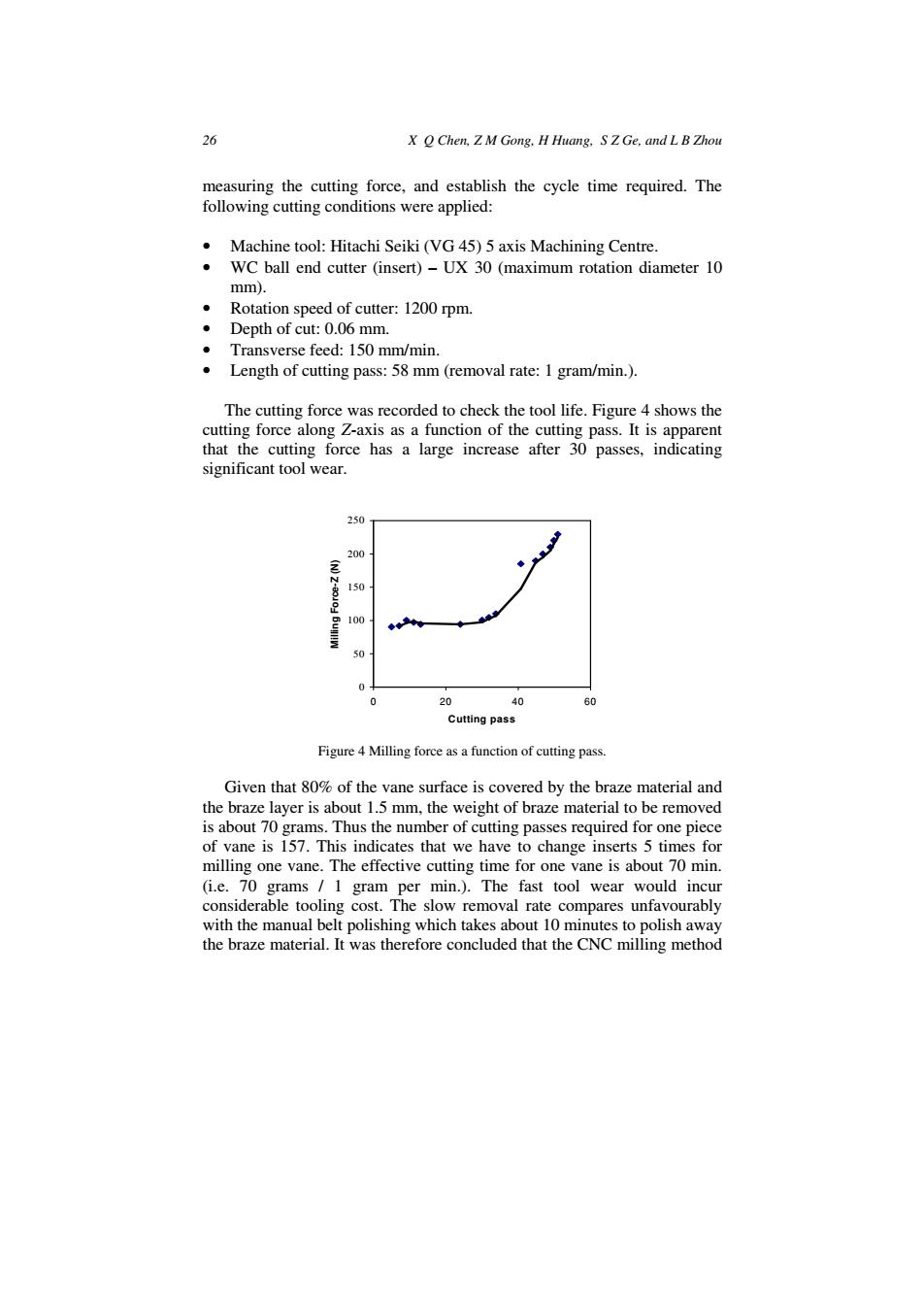

26 X O Chen,Z M Gong,H Huang,S Z Ge,and L B Zhou measuring the cutting force,and establish the cycle time required.The following cutting conditions were applied: .Machine tool:Hitachi Seiki (VG 45)5 axis Machining Centre. WC ball end cutter (insert)-UX 30(maximum rotation diameter 10 mm). Rotation speed of cutter:1200 rpm. Depth of cut:0.06 mm. Transverse feed:150 mm/min. Length of cutting pass:58 mm(removal rate:1 gram/min.). The cutting force was recorded to check the tool life.Figure 4 shows the cutting force along Z-axis as a function of the cutting pass.It is apparent that the cutting force has a large increase after 30 passes,indicating significant tool wear. 250 200 N 150 100 50 0+ 0 20 40 60 Cutting pass Figure 4 Milling force as a function of cutting pass. Given that 80%of the vane surface is covered by the braze material and the braze layer is about 1.5 mm,the weight of braze material to be removed is about 70 grams.Thus the number of cutting passes required for one piece of vane is 157.This indicates that we have to change inserts 5 times for milling one vane.The effective cutting time for one vane is about 70 min. (i.e.70 grams 1 gram per min.).The fast tool wear would incur considerable tooling cost.The slow removal rate compares unfavourably with the manual belt polishing which takes about 10 minutes to polish away the braze material.It was therefore concluded that the CNC milling method26 X Q Chen, Z M Gong, H Huang, S Z Ge, and L B Zhou measuring the cutting force, and establish the cycle time required. The following cutting conditions were applied: • Machine tool: Hitachi Seiki (VG 45) 5 axis Machining Centre. • WC ball end cutter (insert) – UX 30 (maximum rotation diameter 10 mm). • Rotation speed of cutter: 1200 rpm. • Depth of cut: 0.06 mm. • Transverse feed: 150 mm/min. • Length of cutting pass: 58 mm (removal rate: 1 gram/min.). The cutting force was recorded to check the tool life. Figure 4 shows the cutting force along Z-axis as a function of the cutting pass. It is apparent that the cutting force has a large increase after 30 passes, indicating significant tool wear. 0 50 100 150 200 250 0 20 40 60 Cutting pass Milling Force-Z (N) Figure 4 Milling force as a function of cutting pass. Given that 80% of the vane surface is covered by the braze material and the braze layer is about 1.5 mm, the weight of braze material to be removed is about 70 grams. Thus the number of cutting passes required for one piece of vane is 157. This indicates that we have to change inserts 5 times for milling one vane. The effective cutting time for one vane is about 70 min. (i.e. 70 grams / 1 gram per min.). The fast tool wear would incur considerable tooling cost. The slow removal rate compares unfavourably with the manual belt polishing which takes about 10 minutes to polish away the braze material. It was therefore concluded that the CNC milling method