正在加载图片...

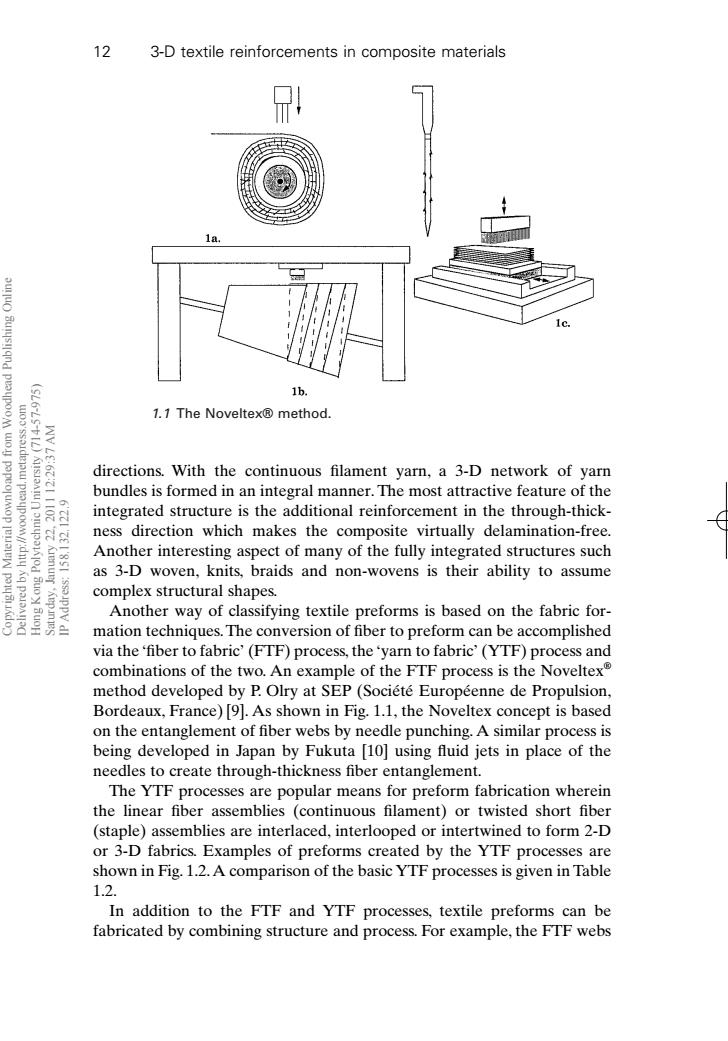

12 3-D textile reinforcements in composite materials 1c. 1h. 1.1 The Noveltex@method. WV LE:6Z directions.With the continuous filament yarn,a 3-D network of yarn bundles is formed in an integral manner.The most attractive feature of the 9 integrated structure is the additional reinforcement in the through-thick- A ness direction which makes the composite virtually delamination-free. Another interesting aspect of many of the fully integrated structures such as 3-D woven,knits,braids and non-wovens is their ability to assume complex structural shapes. Another way of classifying textile preforms is based on the fabric for- mation techniques.The conversion of fiber to preform can be accomplished via the 'fiber to fabric'(FTF)process,the'yarn to fabric'(YTF)process and combinations of the two.An example of the FTF process is the Noveltex method developed by P.Olry at SEP(Societe Europeenne de Propulsion, Bordeaux,France)[9].As shown in Fig.1.1,the Noveltex concept is based on the entanglement of fiber webs by needle punching.A similar process is being developed in Japan by Fukuta [10]using fluid jets in place of the needles to create through-thickness fiber entanglement. The YTF processes are popular means for preform fabrication wherein the linear fiber assemblies (continuous filament)or twisted short fiber (staple)assemblies are interlaced,interlooped or intertwined to form 2-D or 3-D fabrics.Examples of preforms created by the YTF processes are shown in Fig.1.2.A comparison of the basic YTF processes is given in Table 1.2. In addition to the FTF and YTF processes,textile preforms can be fabricated by combining structure and process.For example,the FTF websdirections. With the continuous filament yarn, a 3-D network of yarn bundles is formed in an integral manner. The most attractive feature of the integrated structure is the additional reinforcement in the through-thickness direction which makes the composite virtually delamination-free. Another interesting aspect of many of the fully integrated structures such as 3-D woven, knits, braids and non-wovens is their ability to assume complex structural shapes. Another way of classifying textile preforms is based on the fabric formation techniques. The conversion of fiber to preform can be accomplished via the ‘fiber to fabric’ (FTF) process, the ‘yarn to fabric’ (YTF) process and combinations of the two. An example of the FTF process is the Noveltex® method developed by P. Olry at SEP (Société Européenne de Propulsion, Bordeaux, France) [9]. As shown in Fig. 1.1, the Noveltex concept is based on the entanglement of fiber webs by needle punching. A similar process is being developed in Japan by Fukuta [10] using fluid jets in place of the needles to create through-thickness fiber entanglement. The YTF processes are popular means for preform fabrication wherein the linear fiber assemblies (continuous filament) or twisted short fiber (staple) assemblies are interlaced, interlooped or intertwined to form 2-D or 3-D fabrics. Examples of preforms created by the YTF processes are shown in Fig. 1.2.A comparison of the basic YTF processes is given in Table 1.2. In addition to the FTF and YTF processes, textile preforms can be fabricated by combining structure and process. For example, the FTF webs 12 3-D textile reinforcements in composite materials 1.1 The Noveltex® method. RIC1 7/10/99 7:15 PM Page 12 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:37 AM IP Address: 158.132.122.9