正在加载图片...

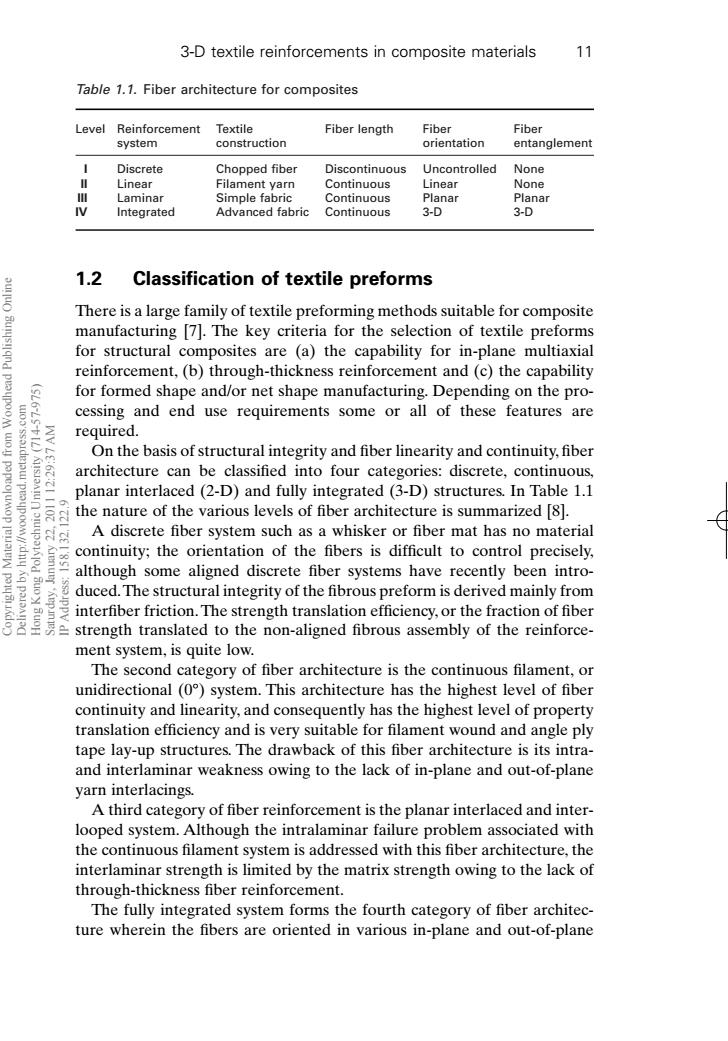

3-D textile reinforcements in composite materials Table 1.1.Fiber architecture for composites Level Reinforcement Textile Fiber length Fiber Fiber system construction orientation entanglement Discrete Chopped fiber Discontinuous Uncontrolled None Linear Filament yarn Continuous Linear None 0 Laminar Simple fabric Continuous Planar Planar V Integrated Advanced fabric Continuous 3-D 3-D 1.2 Classification of textile preforms There is a large family of textile preforming methods suitable for composite manufacturing [7].The key criteria for the selection of textile preforms for structural composites are (a)the capability for in-plane multiaxial reinforcement,(b)through-thickness reinforcement and(c)the capability for formed shape and/or net shape manufacturing.Depending on the pro- cessing and end use requirements some or all of these features are required. On the basis of structural integrity and fiber linearity and continuity,fiber architecture can be classified into four categories:discrete,continuous, planar interlaced (2-D)and fully integrated (3-D)structures.In Table 1.1 the nature of the various levels of fiber architecture is summarized [8]. A discrete fiber system such as a whisker or fiber mat has no material continuity;the orientation of the fibers is difficult to control precisely, although some aligned discrete fiber systems have recently been intro- duced.The structural integrity of the fibrous preform is derived mainly from 具 interfiber friction.The strength translation efficiency,or the fraction of fiber strength translated to the non-aligned fibrous assembly of the reinforce- ment system,is quite low. The second category of fiber architecture is the continuous filament,or unidirectional(0)system.This architecture has the highest level of fiber continuity and linearity,and consequently has the highest level of property translation efficiency and is very suitable for filament wound and angle ply tape lay-up structures.The drawback of this fiber architecture is its intra- and interlaminar weakness owing to the lack of in-plane and out-of-plane yarn interlacings. A third category of fiber reinforcement is the planar interlaced and inter- looped system.Although the intralaminar failure problem associated with the continuous filament system is addressed with this fiber architecture,the interlaminar strength is limited by the matrix strength owing to the lack of through-thickness fiber reinforcement. The fully integrated system forms the fourth category of fiber architec- ture wherein the fibers are oriented in various in-plane and out-of-plane1.2 Classification of textile preforms There is a large family of textile preforming methods suitable for composite manufacturing [7]. The key criteria for the selection of textile preforms for structural composites are (a) the capability for in-plane multiaxial reinforcement, (b) through-thickness reinforcement and (c) the capability for formed shape and/or net shape manufacturing. Depending on the processing and end use requirements some or all of these features are required. On the basis of structural integrity and fiber linearity and continuity, fiber architecture can be classified into four categories: discrete, continuous, planar interlaced (2-D) and fully integrated (3-D) structures. In Table 1.1 the nature of the various levels of fiber architecture is summarized [8]. A discrete fiber system such as a whisker or fiber mat has no material continuity; the orientation of the fibers is difficult to control precisely, although some aligned discrete fiber systems have recently been introduced.The structural integrity of the fibrous preform is derived mainly from interfiber friction.The strength translation efficiency, or the fraction of fiber strength translated to the non-aligned fibrous assembly of the reinforcement system, is quite low. The second category of fiber architecture is the continuous filament, or unidirectional (0°) system. This architecture has the highest level of fiber continuity and linearity, and consequently has the highest level of property translation efficiency and is very suitable for filament wound and angle ply tape lay-up structures. The drawback of this fiber architecture is its intraand interlaminar weakness owing to the lack of in-plane and out-of-plane yarn interlacings. A third category of fiber reinforcement is the planar interlaced and interlooped system. Although the intralaminar failure problem associated with the continuous filament system is addressed with this fiber architecture, the interlaminar strength is limited by the matrix strength owing to the lack of through-thickness fiber reinforcement. The fully integrated system forms the fourth category of fiber architecture wherein the fibers are oriented in various in-plane and out-of-plane 3-D textile reinforcements in composite materials 11 Table 1.1. Fiber architecture for composites Level Reinforcement Textile Fiber length Fiber Fiber system construction orientation entanglement I Discrete Chopped fiber Discontinuous Uncontrolled None II Linear Filament yarn Continuous Linear None III Laminar Simple fabric Continuous Planar Planar IV Integrated Advanced fabric Continuous 3-D 3-D RIC1 7/10/99 7:15 PM Page 11 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:37 AM IP Address: 158.132.122.9