正在加载图片...

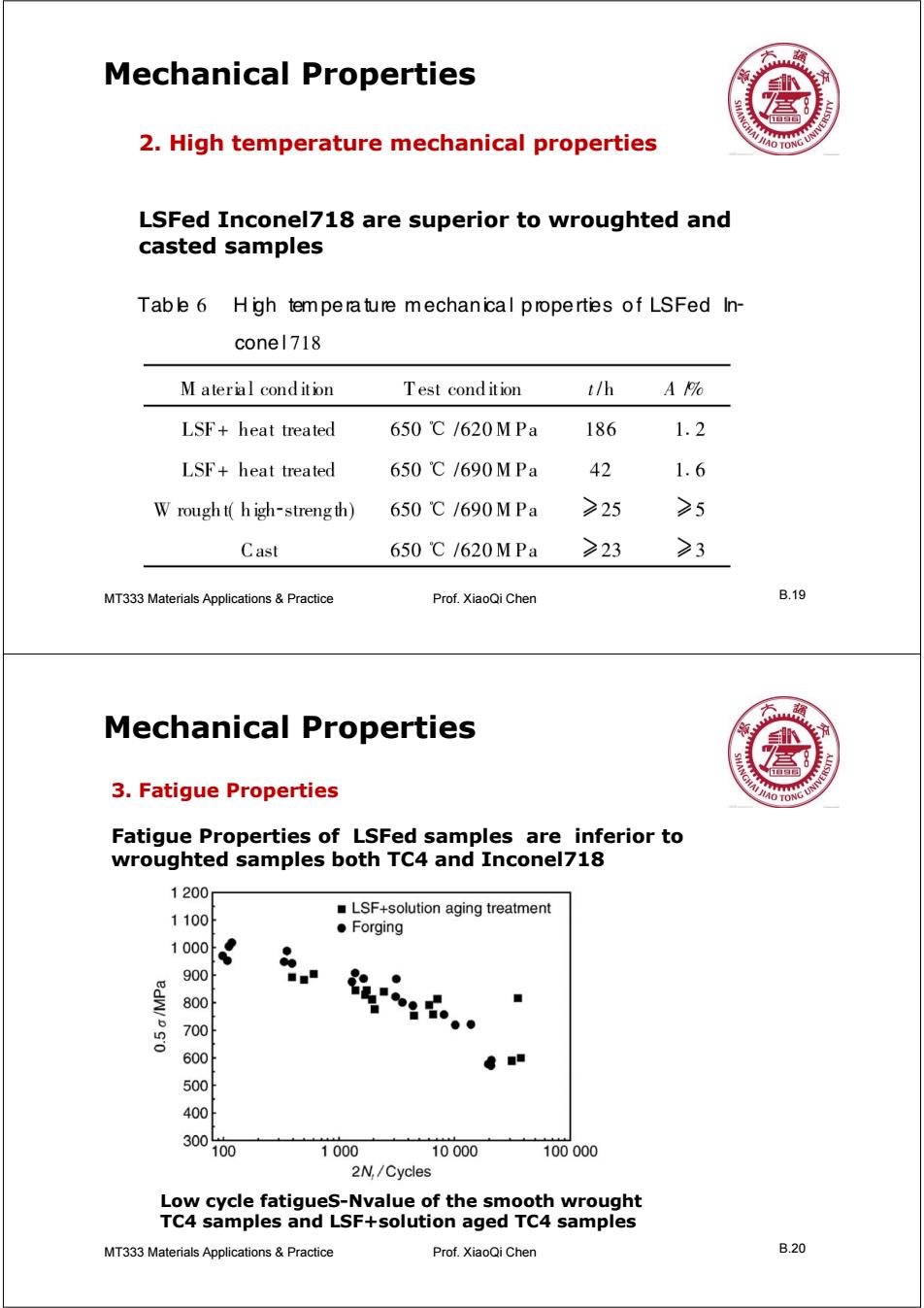

Mechanical Properties 盒 2.High temperature mechanical properties LSFed Inconel718 are superior to wroughted and casted samples Table 6 High temperature mechanical properties of LSFed In- conel718 M aterial condition Test condition t/h A o LSF+heat treated 650℃/620MPa 186 1.2 LSF+heat treated 650℃/690MPa 42 1.6 W rought(high-strength) 650℃/690MPa ≥25 ≥5 Cast 650℃/620MPa ≥23 ≥3 MT333 Materials Applications Practice Prof.XiaoQi Chen B.19 Mechanical Properties 3.Fatigue Properties Fatigue Properties of LSFed samples are inferior to wroughted samples both TC4 and Inconel718 1200 1100 LSF+solution aging treatment ●Forging 1000 900 800 100 600 ■■ 500 400 300 100 1000 10000 100000 2N/Cycles Low cycle fatigueS-Nvalue of the smooth wrought TC4 samples and LSF+solution aged TC4 samples MT333 Materials Applications Practice Prof.XiaoQi Chen B.20MT333 Materials Applications B.19 & Practice Prof. XiaoQi Chen 2. High temperature mechanical properties LSFed Inconel718 are superior to wroughted and casted samples Mechanical Properties MT333 Materials Applications B.20 & Practice Prof. XiaoQi Chen 3. Fatigue Properties Fatigue Properties of LSFed samples are inferior to wroughted samples both TC4 and Inconel718 Low cycle fatigueS-Nvalue of the smooth wrought TC4 samples and LSF+solution aged TC4 samples Mechanical Properties