正在加载图片...

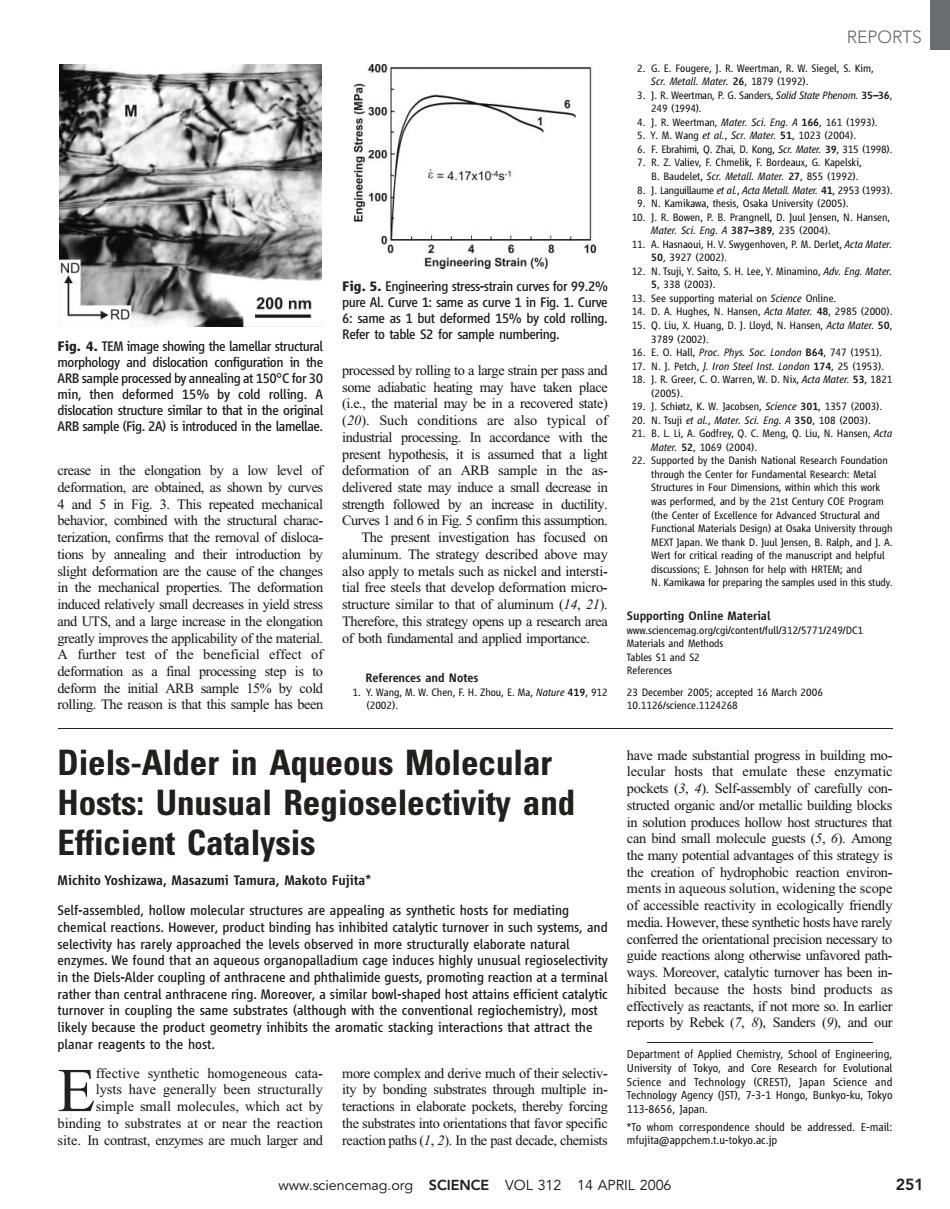

REPORTS 400 2.G.E.Fougere,)R.Weertman,R.W.Siegel,S.Kim, Scr.Metall.Moter.26,1879 (1992). 3.)R.Weertman,P.G.Sanders,Solid Stote Phenom.35-36, 300 249(1994). 4.]R.Weertman,Mater.Sci.Eng.A 166,161 (1993). 5.Y.M.Wang et ol.,Scr.Mater.51,1023 (2004). 200 6.F.Ebrahimi,Q.Zhai,D.Kong,Scr.Moter.39,315 (1998) 7.R.Z.Valiev,F.Chmelik,F.Bordeaux,G.Kapelski. e=4.17x10s1 B.Baudelet,Scr.Metoll.Mater.27,855 (1992). 8.]Languillaume et aL,Acta Metoll Moter.41,2953(1993) 100 9.N.Kamikawa,thesis,Osaka University (2005). 10.]R.Bowen,P.B.Prangnell,D.Juul Jensen,N.Hansen, Mater..Sci.Eng..A387-389,235(2004). 2 4 6 8 10 11.A Hasnaoui,H.V.Swygenhoven,P.M.Derlet,Acta Mater. Engineering Strain(%) 50,3927(2002). 12.N.Tsuji,Y.Saito,S.H.Lee,Y.Minamino,Adv.Eng.Moter. Fig.5.Engineering stress-strain curves for 99.2% 5,338(2003). 200nm pure AL.Curve 1:same as curve 1 in Fig.1.Curve 13.See supporting material on Science Online. RD 14.D.A.Hughes,N.Hansen,Acta Moter.48,2985 (2000). 6:same as 1 but deformed 15%by cold rolling. Refer to table S2 for sample numbering. 15.Q.Liu,X Huang,D.]Lloyd,N.Hansen,Acto Mater.50, Fig.4.TEM image showing the lamellar structural 3789(2002). 16.E.O.Hall,Proc.Phys.Soc.London B64,747 (1951). morphology and dislocation configuration in the processed by rolling to a large strain per pass and 17.N.)Petch,J.Iron Steef Inst.London 174,25 (1953). ARB sample processed by annealing at 150C for 30 18.]R.Greer,C.O.Warren,W.D.Nix,Acta Mater.53,1821 min,then deformed 15%by cold rolling.A some adiabatic heating may have taken place (2005). dislocation structure similar to that in the original (i.e.,the material may be in a recovered state) 19.]Schiotz,K.W.Jacobsen,Science 301,1357 (2003). ARB sample(Fig.2A)is introduced in the lamellae. (20).Such conditions are also typical of 20.N.Tsuji et aL,Mater.Sci.Eng.A 350,108 (2003). industrial processing.In accordance with the 21.B.L Li,A.Godfrey,Q.C.Meng.Q.Liu,N.Hansen,Acto Mater.52,1069(2004). present hypothesis,it is assumed that a light 22.Supported by the Danish National Research Foundation crease in the elongation by a low level of deformation of an ARB sample in the as- through the Center for Fundamental Research:Metal deformation,are obtained,as shown by curves delivered state may induce a small decrease in Structures in Four Dimensions,within which this work 4 and 5 in Fig.3.This repeated mechanical strength followed by an increase in ductility. was performed,and by the 21st Century COE Program behavior,combined with the structural charac- Curves 1 and 6 in Fig.5 confimm this assumption (the Center of Excellence for Advanced Structural and Functional Materials Design)at Osaka University through terization,confirms that the removal of disloca- The present investigation has focused on MEXT Japan.We thank D.Juul Jensen,B.Ralph,and ]A tions by annealing and their introduction by aluminum.The strategy described above may Wert for critical reading of the manuscript and helpful slight deformation are the cause of the changes also apply to metals such as nickel and intersti- discussions;E.Johnson for help with HRTEM;and in the mechanical properties.The deformation tial free steels that develop deformation micro- N.Kamikawa for preparing the samples used in this study. induced relatively small decreases in yield stress structure similar to that of aluminum (/4,2/) and UTS,and a large increase in the elongation Therefore,this strategy opens up a research area Supporting Online Material www.sciencemag.org/cgi/content/full312/5771/249/DC1 greatly improves the applicability of the material. of both fundamental and applied importance. Materials and Methods A further test of the beneficial effect of Tables S1 and S2 deformation as a final processing step is to References References and Notes deform the initial ARB sample 15%by cold 1.Y.Wang,M.W.Chen,F.H.Zhou,E.Ma,Nature 419,912 23 December 2005;accepted 16 March2006 rolling.The reason is that this sample has been (2002). 10.1126/science.1124268 Diels-Alder in Aqueous Molecular have made substantial progress in building mo- lecular hosts that emulate these enzymatic Hosts:Unusual Regioselectivity and pockets (3,4).Self-assembly of carefully con- structed organic and/or metallic building blocks in solution produces hollow host structures that Efficient Catalysis can bind small molecule guests (5,6).Among the many potential advantages of this strategy is Michito Yoshizawa,Masazumi Tamura,Makoto Fujita* the creation of hydrophobic reaction environ- ments in aqueous solution,widening the scope Self-assembled,hollow molecular structures are appealing as synthetic hosts for mediating of accessible reactivity in ecologically friendly chemical reactions.However,product binding has inhibited catalytic turnover in such systems,and media.However,these synthetic hosts have rarely selectivity has rarely approached the levels observed in more structurally elaborate natural conferred the orientational precision necessary to enzymes.We found that an aqueous organopalladium cage induces highly unusual regioselectivity guide reactions along otherwise unfavored path- in the Diels-Alder coupling of anthracene and phthalimide guests,promoting reaction at a terminal ways.Moreover,catalytic tumover has been in- rather than central anthracene ring.Moreover,a similar bowl-shaped host attains efficient catalytic hibited because the hosts bind products as turnover in coupling the same substrates(although with the conventional regiochemistry),most effectively as reactants,if not more so.In earlier likely because the product geometry inhibits the aromatic stacking interactions that attract the reports by Rebek (7,8),Sanders (9),and our planar reagents to the host. Department of Applied Chemistry,School of Engineering ffective synthetic homogeneous cata- more complex and derive much of their selectiv- University of Tokyo,and Core Research for Evolutional lysts have generally been structurally ity by bonding substrates through multiple in- Science and Technology (CREST),Japan Science and Technology Agency (ST),7-3-1 Hongo,Bunkyo-ku,Tokyo simple small molecules,which act by teractions in elaborate pockets,thereby forcing 113-8656,]apan. binding to substrates at or near the reaction the substrates into orientations that favor specific *To whom correspondence should be addressed.E-mail: site.In contrast,enzymes are much larger and reaction paths(1,2).In the past decade,chemists mfujita@appchem.t.u-tokyo.ac.jp www.sciencemag.org SCIENCE VOL 312 14 APRIL 2006 251crease in the elongation by a low level of deformation, are obtained, as shown by curves 4 and 5 in Fig. 3. This repeated mechanical behavior, combined with the structural characterization, confirms that the removal of dislocations by annealing and their introduction by slight deformation are the cause of the changes in the mechanical properties. The deformation induced relatively small decreases in yield stress and UTS, and a large increase in the elongation greatly improves the applicability of the material. A further test of the beneficial effect of deformation as a final processing step is to deform the initial ARB sample 15% by cold rolling. The reason is that this sample has been processed by rolling to a large strain per pass and some adiabatic heating may have taken place (i.e., the material may be in a recovered state) (20). Such conditions are also typical of industrial processing. In accordance with the present hypothesis, it is assumed that a light deformation of an ARB sample in the asdelivered state may induce a small decrease in strength followed by an increase in ductility. Curves 1 and 6 in Fig. 5 confirm this assumption. The present investigation has focused on aluminum. The strategy described above may also apply to metals such as nickel and interstitial free steels that develop deformation microstructure similar to that of aluminum (14, 21). Therefore, this strategy opens up a research area of both fundamental and applied importance. References and Notes 1. Y. Wang, M. W. Chen, F. H. Zhou, E. Ma, Nature 419, 912 (2002). 2. G. E. Fougere, J. R. Weertman, R. W. Siegel, S. Kim, Scr. Metall. Mater. 26, 1879 (1992). 3. J. R. Weertman, P. G. Sanders, Solid State Phenom. 35–36, 249 (1994). 4. J. R. Weertman, Mater. Sci. Eng. A 166, 161 (1993). 5. Y. M. Wang et al., Scr. Mater. 51, 1023 (2004). 6. F. Ebrahimi, Q. Zhai, D. Kong, Scr. Mater. 39, 315 (1998). 7. R. Z. Valiev, F. Chmelik, F. Bordeaux, G. Kapelski, B. Baudelet, Scr. Metall. Mater. 27, 855 (1992). 8. J. Languillaume et al., Acta Metall. Mater. 41, 2953 (1993). 9. N. Kamikawa, thesis, Osaka University (2005). 10. J. R. Bowen, P. B. Prangnell, D. Juul Jensen, N. Hansen, Mater. Sci. Eng. A 387–389, 235 (2004). 11. A. Hasnaoui, H. V. Swygenhoven, P. M. Derlet, Acta Mater. 50, 3927 (2002). 12. N. Tsuji, Y. Saito, S. H. Lee, Y. Minamino, Adv. Eng. Mater. 5, 338 (2003). 13. See supporting material on Science Online. 14. D. A. Hughes, N. Hansen, Acta Mater. 48, 2985 (2000). 15. Q. Liu, X. Huang, D. J. Lloyd, N. Hansen, Acta Mater. 50, 3789 (2002). 16. E. O. Hall, Proc. Phys. Soc. London B64, 747 (1951). 17. N. J. Petch, J. Iron Steel Inst. London 174, 25 (1953). 18. J. R. Greer, C. O. Warren, W. D. Nix, Acta Mater. 53, 1821 (2005). 19. J. Schiøtz, K. W. Jacobsen, Science 301, 1357 (2003). 20. N. Tsuji et al., Mater. Sci. Eng. A 350, 108 (2003). 21. B. L. Li, A. Godfrey, Q. C. Meng, Q. Liu, N. Hansen, Acta Mater. 52, 1069 (2004). 22. Supported by the Danish National Research Foundation through the Center for Fundamental Research: Metal Structures in Four Dimensions, within which this work was performed, and by the 21st Century COE Program (the Center of Excellence for Advanced Structural and Functional Materials Design) at Osaka University through MEXT Japan. We thank D. Juul Jensen, B. Ralph, and J. A. Wert for critical reading of the manuscript and helpful discussions; E. Johnson for help with HRTEM; and N. Kamikawa for preparing the samples used in this study. Supporting Online Material www.sciencemag.org/cgi/content/full/312/5771/249/DC1 Materials and Methods Tables S1 and S2 References 23 December 2005; accepted 16 March 2006 10.1126/science.1124268 Diels-Alder in Aqueous Molecular Hosts: Unusual Regioselectivity and Efficient Catalysis Michito Yoshizawa, Masazumi Tamura, Makoto Fujita* Self-assembled, hollow molecular structures are appealing as synthetic hosts for mediating chemical reactions. However, product binding has inhibited catalytic turnover in such systems, and selectivity has rarely approached the levels observed in more structurally elaborate natural enzymes. We found that an aqueous organopalladium cage induces highly unusual regioselectivity in the Diels-Alder coupling of anthracene and phthalimide guests, promoting reaction at a terminal rather than central anthracene ring. Moreover, a similar bowl-shaped host attains efficient catalytic turnover in coupling the same substrates (although with the conventional regiochemistry), most likely because the product geometry inhibits the aromatic stacking interactions that attract the planar reagents to the host. Effective synthetic homogeneous catalysts have generally been structurally simple small molecules, which act by binding to substrates at or near the reaction site. In contrast, enzymes are much larger and more complex and derive much of their selectivity by bonding substrates through multiple interactions in elaborate pockets, thereby forcing the substrates into orientations that favor specific reaction paths (1, 2). In the past decade, chemists have made substantial progress in building molecular hosts that emulate these enzymatic pockets (3, 4). Self-assembly of carefully constructed organic and/or metallic building blocks in solution produces hollow host structures that can bind small molecule guests (5, 6). Among the many potential advantages of this strategy is the creation of hydrophobic reaction environments in aqueous solution, widening the scope of accessible reactivity in ecologically friendly media. However, these synthetic hosts have rarely conferred the orientational precision necessary to guide reactions along otherwise unfavored pathways. Moreover, catalytic turnover has been inhibited because the hosts bind products as effectively as reactants, if not more so. In earlier reports by Rebek (7, 8), Sanders (9), and our Fig. 4. TEM image showing the lamellar structural morphology and dislocation configuration in the ARB sample processed by annealing at 150-C for 30 min, then deformed 15% by cold rolling. A dislocation structure similar to that in the original ARB sample (Fig. 2A) is introduced in the lamellae. Fig. 5. Engineering stress-strain curves for 99.2% pure Al. Curve 1: same as curve 1 in Fig. 1. Curve 6: same as 1 but deformed 15% by cold rolling. Refer to table S2 for sample numbering. Department of Applied Chemistry, School of Engineering, University of Tokyo, and Core Research for Evolutional Science and Technology (CREST), Japan Science and Technology Agency (JST), 7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan. *To whom correspondence should be addressed. E-mail: mfujita@appchem.t.u-tokyo.ac.jp REPORTS www.sciencemag.org SCIENCE VOL 312 14 APRIL 2006 251