正在加载图片...

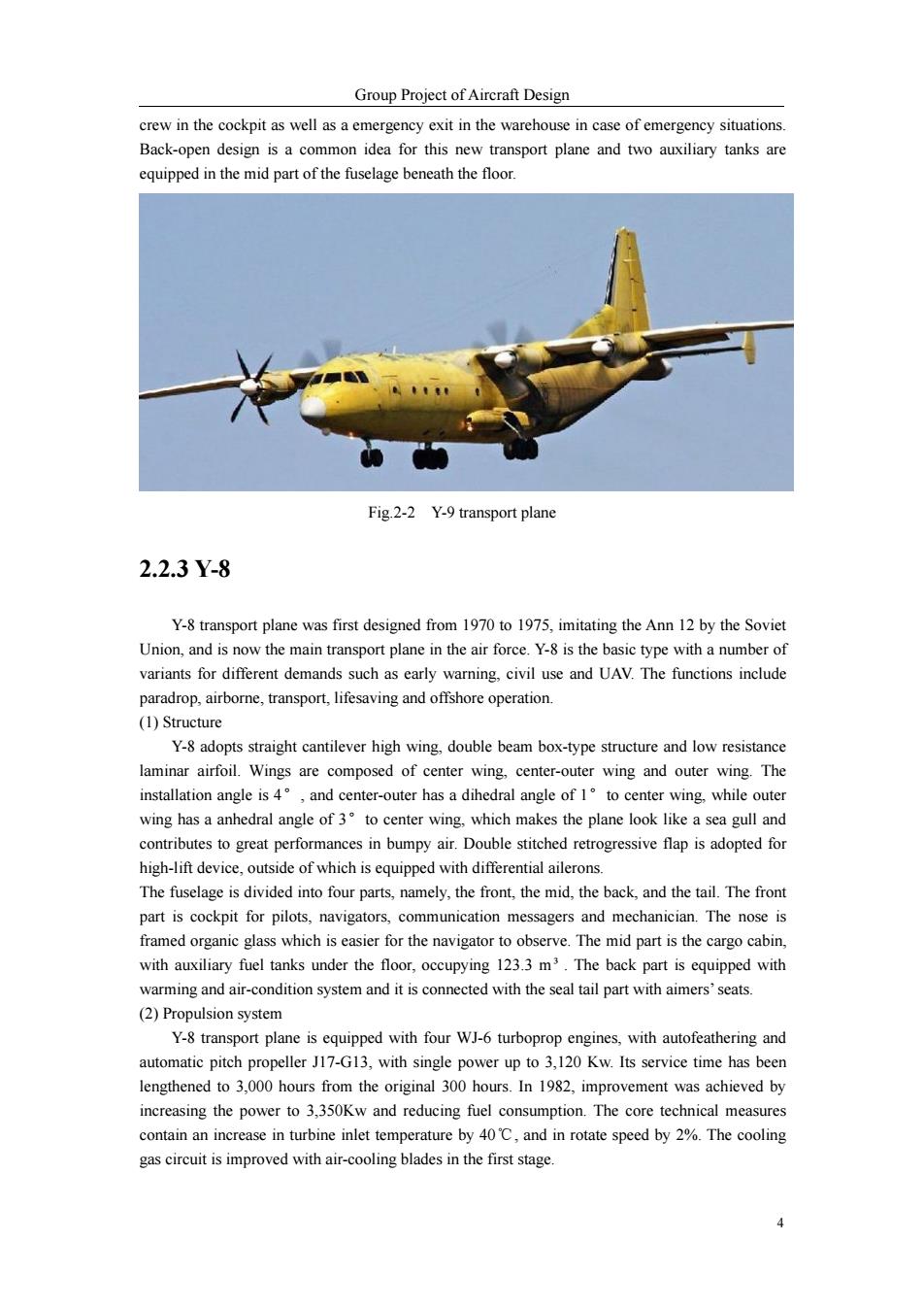

Group Project of Aircraft Design crew in the cockpit as well as a emergency exit in the warehouse in case of emergency situations. Back-open design is a common idea for this new transport plane and two auxiliary tanks are equipped in the mid part of the fuselage beneath the floor. Fig.2-2 Y-9 transport plane 2.2.3Y-8 Y-8 transport plane was first designed from 1970 to 1975,imitating the Ann 12 by the Soviet Union,and is now the main transport plane in the air force.Y-8 is the basic type with a number of variants for different demands such as early warning,civil use and UAV.The functions include paradrop,airborne,transport,lifesaving and offshore operation. (1)Structure Y-8 adopts straight cantilever high wing,double beam box-type structure and low resistance laminar airfoil.Wings are composed of center wing,center-outer wing and outer wing.The installation angle is 4,and center-outer has a dihedral angle of 1 to center wing,while outer wing has a anhedral angle of 3 to center wing,which makes the plane look like a sea gull and contributes to great performances in bumpy air.Double stitched retrogressive flap is adopted for high-lift device,outside of which is equipped with differential ailerons. The fuselage is divided into four parts,namely,the front,the mid,the back,and the tail.The front part is cockpit for pilots,navigators,communication messagers and mechanician.The nose is framed organic glass which is easier for the navigator to observe.The mid part is the cargo cabin, with auxiliary fuel tanks under the floor,occupying 123.3 m3.The back part is equipped with warming and air-condition system and it is connected with the seal tail part with aimers'seats. (2)Propulsion system Y-8 transport plane is equipped with four WJ-6 turboprop engines,with autofeathering and automatic pitch propeller J17-G13,with single power up to 3,120 Kw.Its service time has been lengthened to 3,000 hours from the original 300 hours.In 1982,improvement was achieved by increasing the power to 3,350Kw and reducing fuel consumption.The core technical measures contain an increase in turbine inlet temperature by 40C,and in rotate speed by 2%.The cooling gas circuit is improved with air-cooling blades in the first stage. 4Group Project of Aircraft Design 4 crew in the cockpit as well as a emergency exit in the warehouse in case of emergency situations. Back-open design is a common idea for this new transport plane and two auxiliary tanks are equipped in the mid part of the fuselage beneath the floor. Fig.2-2 Y-9 transport plane 2.2.3 Y-8 Y-8 transport plane was first designed from 1970 to 1975, imitating the Ann 12 by the Soviet Union, and is now the main transport plane in the air force. Y-8 is the basic type with a number of variants for different demands such as early warning, civil use and UAV. The functions include paradrop, airborne, transport, lifesaving and offshore operation. (1) Structure Y-8 adopts straight cantilever high wing, double beam box-type structure and low resistance laminar airfoil. Wings are composed of center wing, center-outer wing and outer wing. The installation angle is 4°, and center-outer has a dihedral angle of 1°to center wing, while outer wing has a anhedral angle of 3°to center wing, which makes the plane look like a sea gull and contributes to great performances in bumpy air. Double stitched retrogressive flap is adopted for high-lift device, outside of which is equipped with differential ailerons. The fuselage is divided into four parts, namely, the front, the mid, the back, and the tail. The front part is cockpit for pilots, navigators, communication messagers and mechanician. The nose is framed organic glass which is easier for the navigator to observe. The mid part is the cargo cabin, with auxiliary fuel tanks under the floor, occupying 123.3 m³ . The back part is equipped with warming and air-condition system and it is connected with the seal tail part with aimers’seats. (2) Propulsion system Y-8 transport plane is equipped with four WJ-6 turboprop engines, with autofeathering and automatic pitch propeller J17-G13, with single power up to 3,120 Kw. Its service time has been lengthened to 3,000 hours from the original 300 hours. In 1982, improvement was achieved by increasing the power to 3,350Kw and reducing fuel consumption. The core technical measures contain an increase in turbine inlet temperature by 40℃, and in rotate speed by 2%. The cooling gas circuit is improved with air-cooling blades in the first stage