正在加载图片...

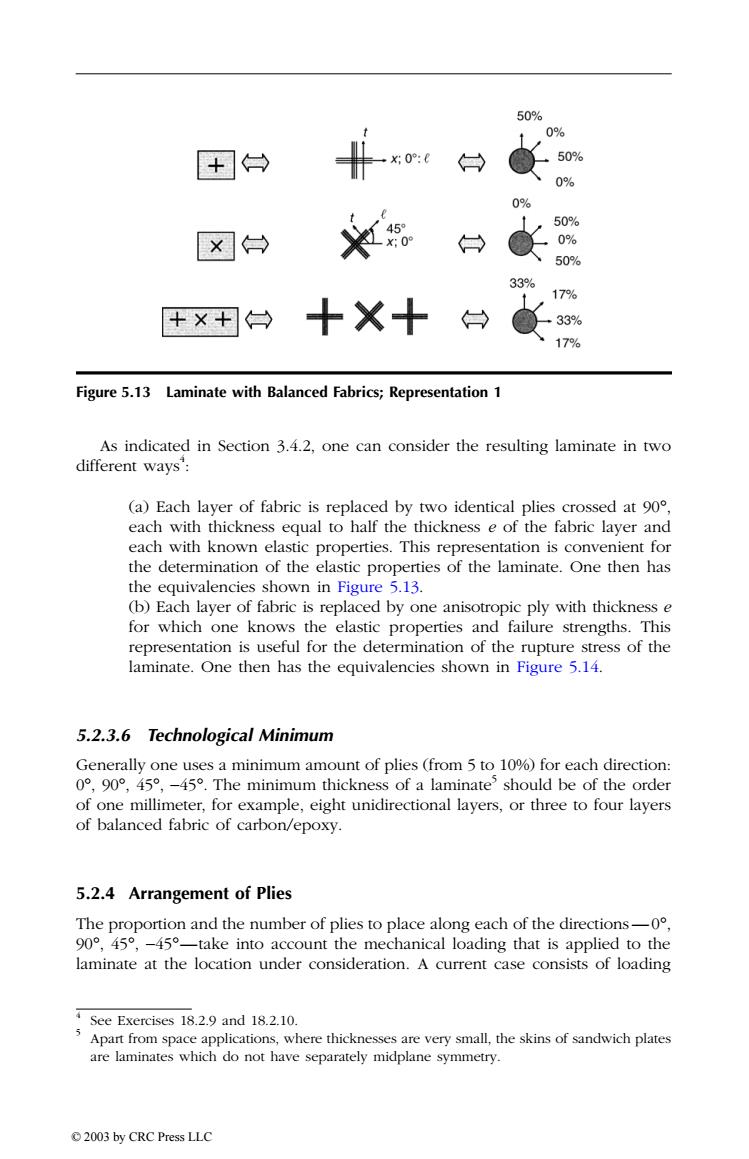

50% 0% +台 x30°: 台 50% 0% 0% 50% ×台 0% 50% 33% 17% +×+台 十X+ ) ,33% 17% Figure 5.13 Laminate with Balanced Fabrics;Representation 1 As indicated in Section 3.4.2,one can consider the resulting laminate in two different ways': (a)Each layer of fabric is replaced by two identical plies crossed at 90 each with thickness equal to half the thickness e of the fabric layer and each with known elastic properties.This representation is convenient for the determination of the elastic properties of the laminate.One then has the equivalencies shown in Figure 5.13. (b)Each layer of fabric is replaced by one anisotropic ply with thickness e for which one knows the elastic properties and failure strengths.This representation is useful for the determination of the rupture stress of the laminate.One then has the equivalencies shown in Figure 5.14. 5.2.3.6 Technological Minimum Generally one uses a minimum amount of plies (from 5 to 10%)for each direction: 0°,90°,45°,-45°.The minimum thickness of a laminate3 should be of the order of one millimeter,for example,eight unidirectional layers,or three to four layers of balanced fabric of carbon/epoxy. 5.2.4 Arrangement of Plies The proportion and the number of plies to place along each of the directions-0 90°,45°,-45°-take into account the mechanical loading that is applied to the laminate at the location under consideration.A current case consists of loading 4 See Exercises 18.2.9 and 18.2.10. s Apart from space applications,where thicknesses are very small,the skins of sandwich plates are laminates which do not have separately midplane symmetry. 2003 by CRC Press LLCAs indicated in Section 3.4.2, one can consider the resulting laminate in two different ways 4 : (a) Each layer of fabric is replaced by two identical plies crossed at 90∞, each with thickness equal to half the thickness e of the fabric layer and each with known elastic properties. This representation is convenient for the determination of the elastic properties of the laminate. One then has the equivalencies shown in Figure 5.13. (b) Each layer of fabric is replaced by one anisotropic ply with thickness e for which one knows the elastic properties and failure strengths. This representation is useful for the determination of the rupture stress of the laminate. One then has the equivalencies shown in Figure 5.14. 5.2.3.6 Technological Minimum Generally one uses a minimum amount of plies (from 5 to 10%) for each direction: 0∞, 90∞, 45∞, -45∞. The minimum thickness of a laminate 5 should be of the order of one millimeter, for example, eight unidirectional layers, or three to four layers of balanced fabric of carbon/epoxy. 5.2.4 Arrangement of Plies The proportion and the number of plies to place along each of the directions—0∞, 90∞, 45∞, -45∞—take into account the mechanical loading that is applied to the laminate at the location under consideration. A current case consists of loading Figure 5.13 Laminate with Balanced Fabrics; Representation 1 4 See Exercises 18.2.9 and 18.2.10. 5 Apart from space applications, where thicknesses are very small, the skins of sandwich plates are laminates which do not have separately midplane symmetry. TX846_Frame_C05 Page 78 Monday, November 18, 2002 12:09 PM © 2003 by CRC Press LLC