正在加载图片...

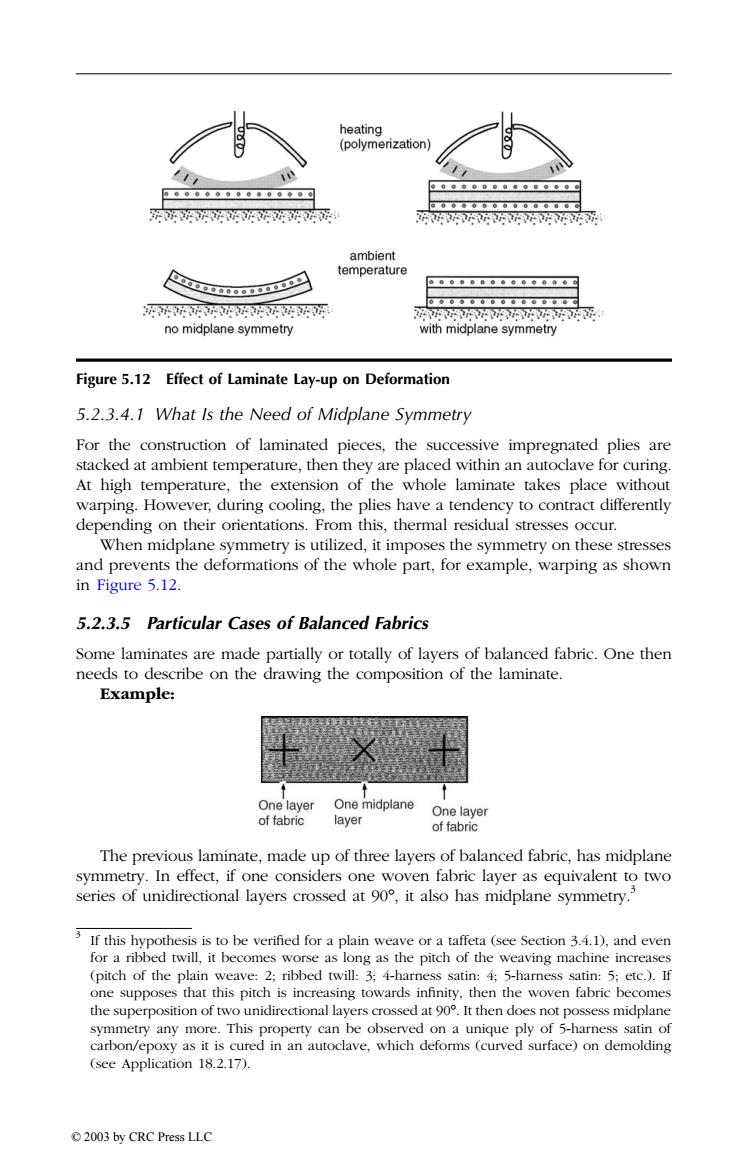

heating (polymerization) ambient temperature aaoow2 0000.00000●●0● 3 3 no midplane symmetry with midplane symmetry Figure 5.12 Effect of Laminate Lay-up on Deformation 5.2.3.4.1 What Is the Need of Midplane Symmetry For the construction of laminated pieces,the successive impregnated plies are stacked at ambient temperature,then they are placed within an autoclave for curing. At high temperature,the extension of the whole laminate takes place without warping.However,during cooling,the plies have a tendency to contract differently depending on their orientations.From this,thermal residual stresses occur. When midplane symmetry is utilized,it imposes the symmetry on these stresses and prevents the deformations of the whole part,for example,warping as shown in Figure 5.12 5.2.3.5 Particular Cases of Balanced Fabrics Some laminates are made partially or totally of layers of balanced fabric.One then needs to describe on the drawing the composition of the laminate. Example: One layer One midplane One layer of fabric layer of fabric The previous laminate,made up of three layers of balanced fabric,has midplane symmetry.In effect,if one considers one woven fabric layer as equivalent to two series of unidirectional layers crossed at 90,it also has midplane symmetry.3 3 If this hypothesis is to be verified for a plain weave or a taffeta (see Section 3.4.1),and even for a ribbed twill,it becomes worse as long as the pitch of the weaving machine increases (pitch of the plain weave:2;ribbed twill:3;4-harness satin:4;5-harness satin:5;etc.).If one supposes that this pitch is increasing towards infinity,then the woven fabric becomes the superposition of two unidirectional layers crossed at 90.It then does not possess midplane symmetry any more.This property can be observed on a unique ply of 5-harness satin of carbon/epoxy as it is cured in an autoclave,which deforms(curved surface)on demolding (see Application 18.2.17). 2003 by CRC Press LLC5.2.3.4.1 What Is the Need of Midplane Symmetry For the construction of laminated pieces, the successive impregnated plies are stacked at ambient temperature, then they are placed within an autoclave for curing. At high temperature, the extension of the whole laminate takes place without warping. However, during cooling, the plies have a tendency to contract differently depending on their orientations. From this, thermal residual stresses occur. When midplane symmetry is utilized, it imposes the symmetry on these stresses and prevents the deformations of the whole part, for example, warping as shown in Figure 5.12. 5.2.3.5 Particular Cases of Balanced Fabrics Some laminates are made partially or totally of layers of balanced fabric. One then needs to describe on the drawing the composition of the laminate. Example: The previous laminate, made up of three layers of balanced fabric, has midplane symmetry. In effect, if one considers one woven fabric layer as equivalent to two series of unidirectional layers crossed at 90∞, it also has midplane symmetry. 3 Figure 5.12 Effect of Laminate Lay-up on Deformation 3 If this hypothesis is to be verified for a plain weave or a taffeta (see Section 3.4.1), and even for a ribbed twill, it becomes worse as long as the pitch of the weaving machine increases (pitch of the plain weave: 2; ribbed twill: 3; 4-harness satin: 4; 5-harness satin: 5; etc.). If one supposes that this pitch is increasing towards infinity, then the woven fabric becomes the superposition of two unidirectional layers crossed at 90∞. It then does not possess midplane symmetry any more. This property can be observed on a unique ply of 5-harness satin of carbon/epoxy as it is cured in an autoclave, which deforms (curved surface) on demolding (see Application 18.2.17). TX846_Frame_C05 Page 77 Monday, November 18, 2002 12:09 PM © 2003 by CRC Press LLC