正在加载图片...

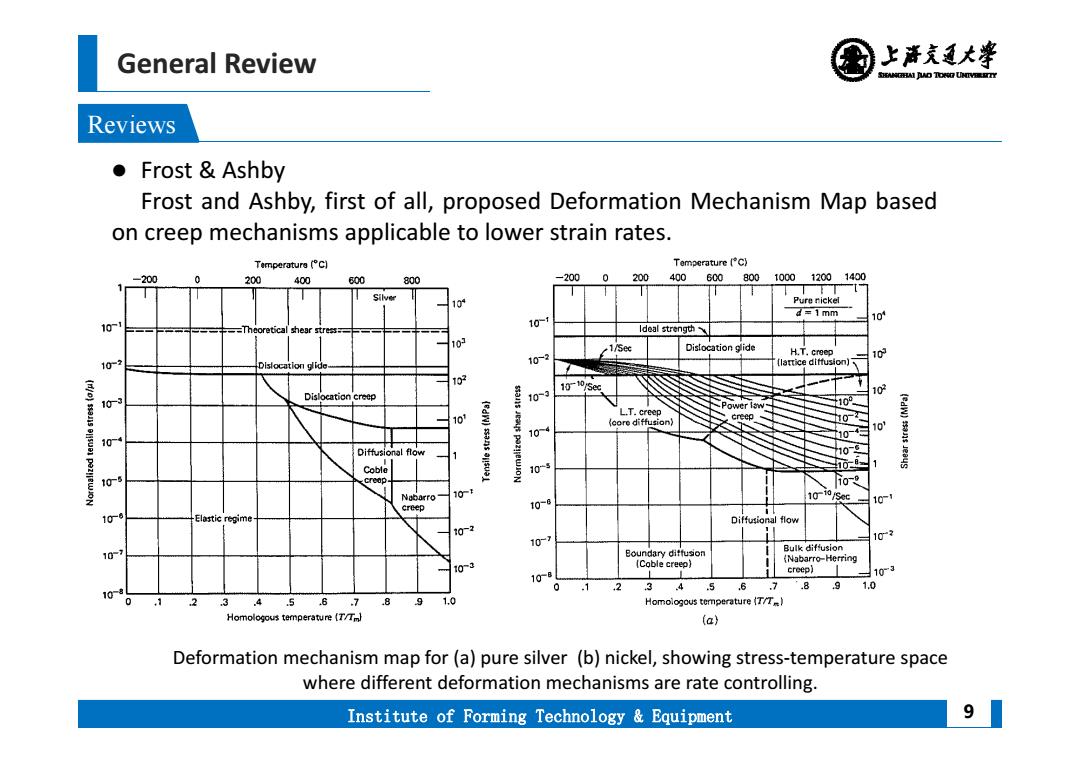

General Review 上清充通大¥ SHEAMGRAI DUD TONO UHTVEREETTY Reviews ● Frost Ashby Frost and Ashby,first of all,proposed Deformation Mechanism Map based on creep mechanisms applicable to lower strain rates. Temperature(°Cl Temperature [C) -200 200 400 00 800 -2000 200 400600.800 100012001400 104 Pure nickel d=1mm 10 10 10 Theoretical shear stress Ideal strength 10N 1/Sec Distocation glide H.T.creep 10 102 102 lattice ditfusion)、 101o5e Dislocation creep 102 10 10-3 D Power law- 102 10 (edw) L.T.creep core diffusion) eep、 104 10 10 10- Diffusional ftow 10 Coble 10 10T 10- 10 10 10- creep 108 10 Elastic regime Diffusional flow 107 10 10 Boundary diftusion Bulk diffusion 103 (Coble creep) (Nabarro-Herring 10a creep) 103 .4 .7 .89 1.0 10 .1 2 3 .3 4.5 .6.7 9 1.0 Homologous temperature (T/T) Homologous temperature(/Tm (a} Deformation mechanism map for(a)pure silver (b)nickel,showing stress-temperature space where different deformation mechanisms are rate controlling. Institute of Forming Technology Equipment 9General Review Institute of Forming Technology & Equipment Reviews 9 Frost & Ashby Frost and Ashby, first of all, proposed Deformation Mechanism Map based on creep mechanisms applicable to lower strain rates. Deformation mechanism map for (a) pure silver (b) nickel, showing stress‐temperature space where different deformation mechanisms are rate controlling