正在加载图片...

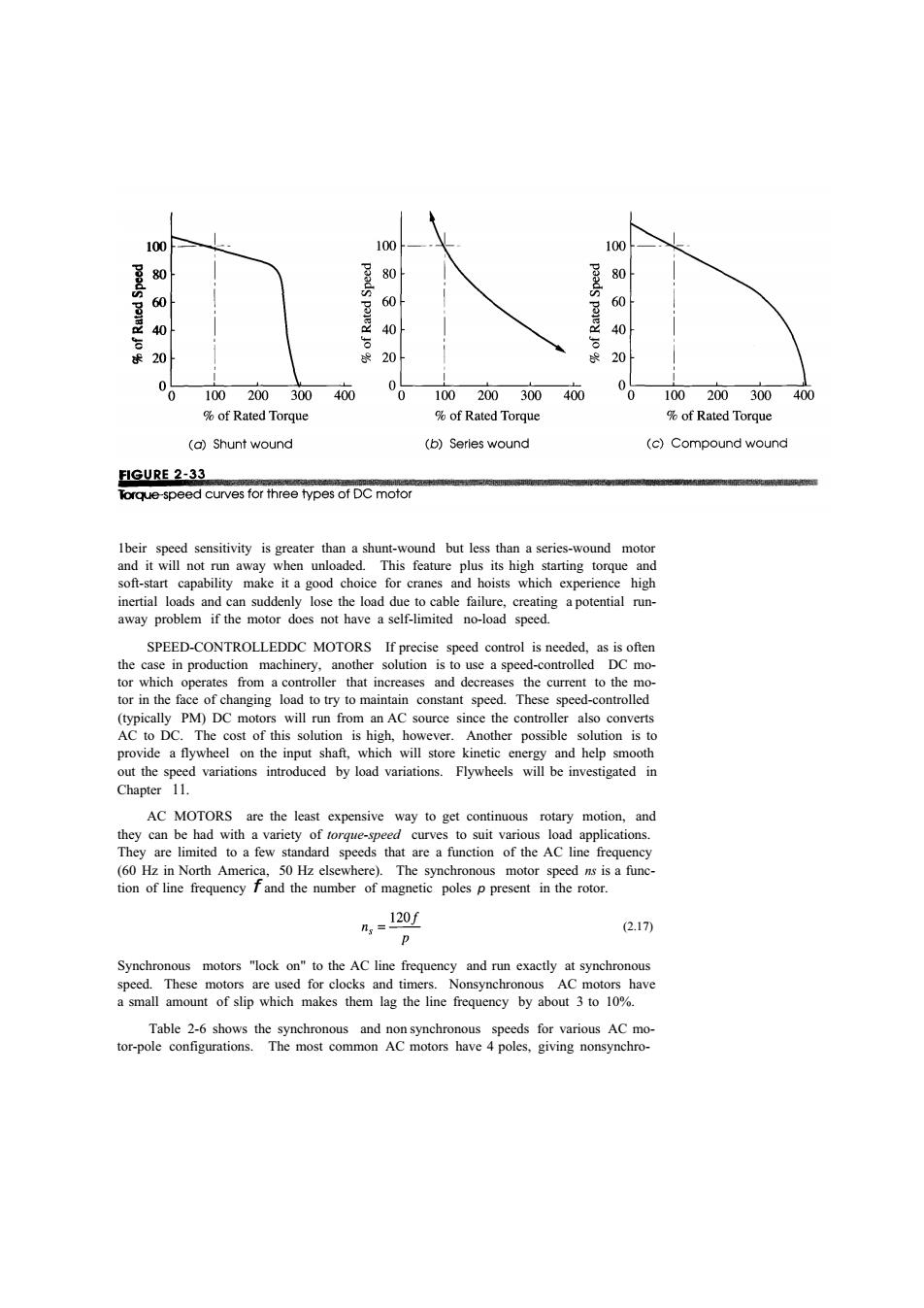

100 100 100 四 60 % 60 40 40 40 20 30 20 0 0 0/ 0 100200300 400 0 100200300400 0 100200300400 %of Rated Torque of Rated Torque of Rated Torque (a)Shunt wound (b)Serles wound (c)Compound wound FIGURE 2-33 Torque-speed curves for three types of DC motor Ibeir speed sensitivity is greater than a shunt-wound but less than a series-wound motor and it will not run away when unloaded.This feature plus its high starting torque and soft-start capability make it a good choice for cranes and hoists which experience high inertial loads and can suddenly lose the load due to cable failure,creating a potential run- away problem if the motor does not have a self-limited no-load speed. SPEED-CONTROLLEDDC MOTORS If precise speed control is needed,as is often the case in production machinery,another solution is to use a speed-controlled DC mo- tor which operates from a controller that increases and decreases the current to the mo- tor in the face of changing load to try to maintain constant speed.These speed-controlled (typically PM)DC motors will run from an AC source since the controller also converts AC to DC.The cost of this solution is high,however.Another possible solution is to provide a flywheel on the input shaft,which will store kinetic energy and help smooth out the speed variations introduced by load variations.Flywheels will be investigated in Chapter 11. AC MOTORS are the least expensive way to get continuous rotary motion,and they can be had with a variety of torque-speed curves to suit various load applications. They are limited to a few standard speeds that are a function of the AC line frequency (60 Hz in North America,50 Hz elsewhere).The synchronous motor speed ns is a func- tion of line frequency I and the number of magnetic poles p present in the rotor. %,=1204 (2.17) p Synchronous motors "lock on"to the AC line frequency and run exactly at synchronous speed.These motors are used for clocks and timers.Nonsynchronous AC motors have a small amount of slip which makes them lag the line frequency by about 3 to 10%. Table 2-6 shows the synchronous and non synchronous speeds for various AC mo- tor-pole configurations.The most common AC motors have 4 poles,giving nonsynchro-1beir speed sensitivity is greater than a shunt-wound but less than a series-wound motor and it will not run away when unloaded. This feature plus its high starting torque and soft-start capability make it a good choice for cranes and hoists which experience high inertial loads and can suddenly lose the load due to cable failure, creating a potential runaway problem if the motor does not have a self-limited no-load speed. SPEED-CONTROLLEDDC MOTORS If precise speed control is needed, as is often the case in production machinery, another solution is to use a speed-controlled DC motor which operates from a controller that increases and decreases the current to the motor in the face of changing load to try to maintain constant speed. These speed-controlled (typically PM) DC motors will run from an AC source since the controller also converts AC to DC. The cost of this solution is high, however. Another possible solution is to provide a flywheel on the input shaft, which will store kinetic energy and help smooth out the speed variations introduced by load variations. Flywheels will be investigated in Chapter 11. AC MOTORS are the least expensive way to get continuous rotary motion, and they can be had with a variety of torque-speed curves to suit various load applications. They are limited to a few standard speeds that are a function of the AC line frequency (60 Hz in North America, 50 Hz elsewhere). The synchronous motor speed ns is a function of line frequency f and the number of magnetic poles p present in the rotor. (2.17) Synchronous motors "lock on" to the AC line frequency and run exactly at synchronous speed. These motors are used for clocks and timers. Nonsynchronous AC motors have a small amount of slip which makes them lag the line frequency by about 3 to 10%. Table 2-6 shows the synchronous and non synchronous speeds for various AC motor-pole configurations. The most common AC motors have 4 poles, giving nonsynchro-