正在加载图片...

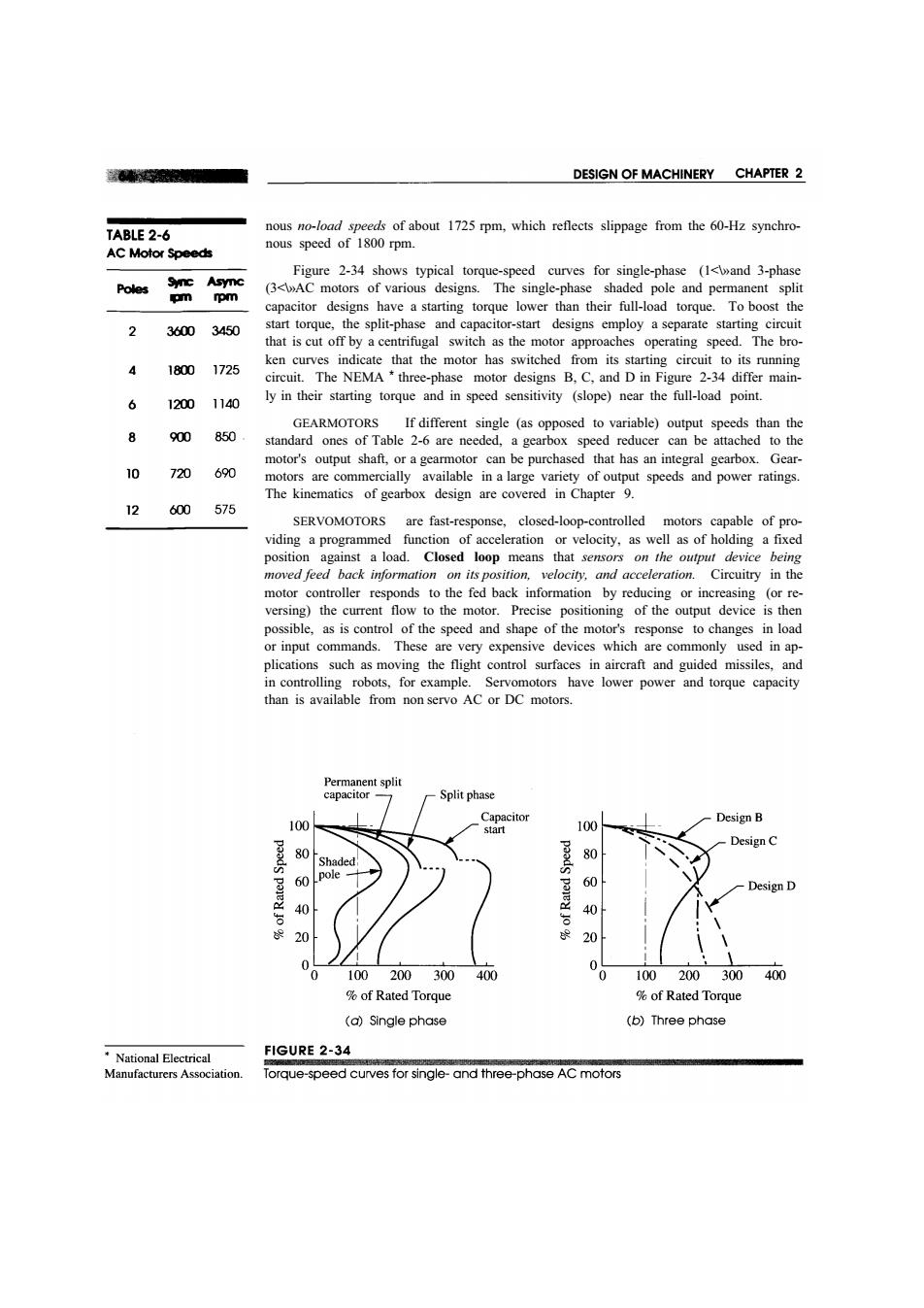

DESIGN OF MACHINERY CHAPTER 2 TABLE 2-6 nous no-load speeds of about 1725 rpm,which reflects slippage from the 60-Hz synchro- AC Motor Speeds nous speed of 1800 rpm. Figure 2-34 shows typical torque-speed curves for single-phase (1<and 3-phase Poles Sync Async (3<AC motors of various designs.The single-phase shaded pole and permanent split m rpm capacitor designs have a starting torque lower than their full-load torque.To boost the 2 3600 3450 start torque,the split-phase and capacitor-start designs employ a separate starting circuit that is cut off by a centrifugal switch as the motor approaches operating speed.The bro- ken curves indicate that the motor has switched from its starting circuit to its running 4 1800 1725 circuit.The NEMA*three-phase motor designs B,C,and D in Figure 2-34 differ main- b 1200 1140 ly in their starting torque and in speed sensitivity (slope)near the full-load point. GEARMOTORS If different single (as opposed to variable)output speeds than the 900 850 standard ones of Table 2-6 are needed,a gearbox speed reducer can be attached to the motor's output shaft,or a gearmotor can be purchased that has an integral gearbox.Gear- 10 720 690 motors are commercially available in a large variety of output speeds and power ratings. The kinematics of gearbox design are covered in Chapter 9. 12 600 575 SERVOMOTORS are fast-response,closed-loop-controlled motors capable of pro- viding a programmed function of acceleration or velocity,as well as of holding a fixed position against a load.Closed loop means that sensors on the output device being moved feed back information on its position,velocity,and acceleration.Circuitry in the motor controller responds to the fed back information by reducing or increasing (or re- versing)the current flow to the motor.Precise positioning of the output device is then possible,as is control of the speed and shape of the motor's response to changes in load or input commands.These are very expensive devices which are commonly used in ap- plications such as moving the flight control surfaces in aircraft and guided missiles,and in controlling robots,for example.Servomotors have lower power and torque capacity than is available from non servo AC or DC motors. Permanent split capacitor Split phase Capacitor Design B 100 start 100 Design C 80 Shaded 80 60 pole 60 Design D 40 40 20 0 100200300 400 100200 300 400 %of Rated Torque %of Rated Torque (a)Single phase (b)Three phase National Electrical FIGURE 2-34 Manufacturers Association. Torque-speed curves for single-and three-phase AC motorsnous no-load speeds of about 1725 rpm, which reflects slippage from the 60-Hz synchronous speed of 1800 rpm. Figure 2-34 shows typical torque-speed curves for single-phase (1<\»and 3-phase (3<\»AC motors of various designs. The single-phase shaded pole and permanent split capacitor designs have a starting torque lower than their full-load torque. To boost the start torque, the split-phase and capacitor-start designs employ a separate starting circuit that is cut off by a centrifugal switch as the motor approaches operating speed. The broken curves indicate that the motor has switched from its starting circuit to its running circuit. The NEMA * three-phase motor designs B, C, and D in Figure 2-34 differ mainly in their starting torque and in speed sensitivity (slope) near the full-load point. GEARMOTORS If different single (as opposed to variable) output speeds than the standard ones of Table 2-6 are needed, a gearbox speed reducer can be attached to the motor's output shaft, or a gearmotor can be purchased that has an integral gearbox. Gearmotors are commercially available in a large variety of output speeds and power ratings. The kinematics of gearbox design are covered in Chapter 9. SERVOMOTORS are fast-response, closed-loop-controlled motors capable of providing a programmed function of acceleration or velocity, as well as of holding a fixed position against a load. Closed loop means that sensors on the output device being moved feed back information on its position, velocity, and acceleration. Circuitry in the motor controller responds to the fed back information by reducing or increasing (or reversing) the current flow to the motor. Precise positioning of the output device is then possible, as is control of the speed and shape of the motor's response to changes in load or input commands. These are very expensive devices which are commonly used in applications such as moving the flight control surfaces in aircraft and guided missiles, and in controlling robots, for example. Servomotors have lower power and torque capacity than is available from non servo AC or DC motors