正在加载图片...

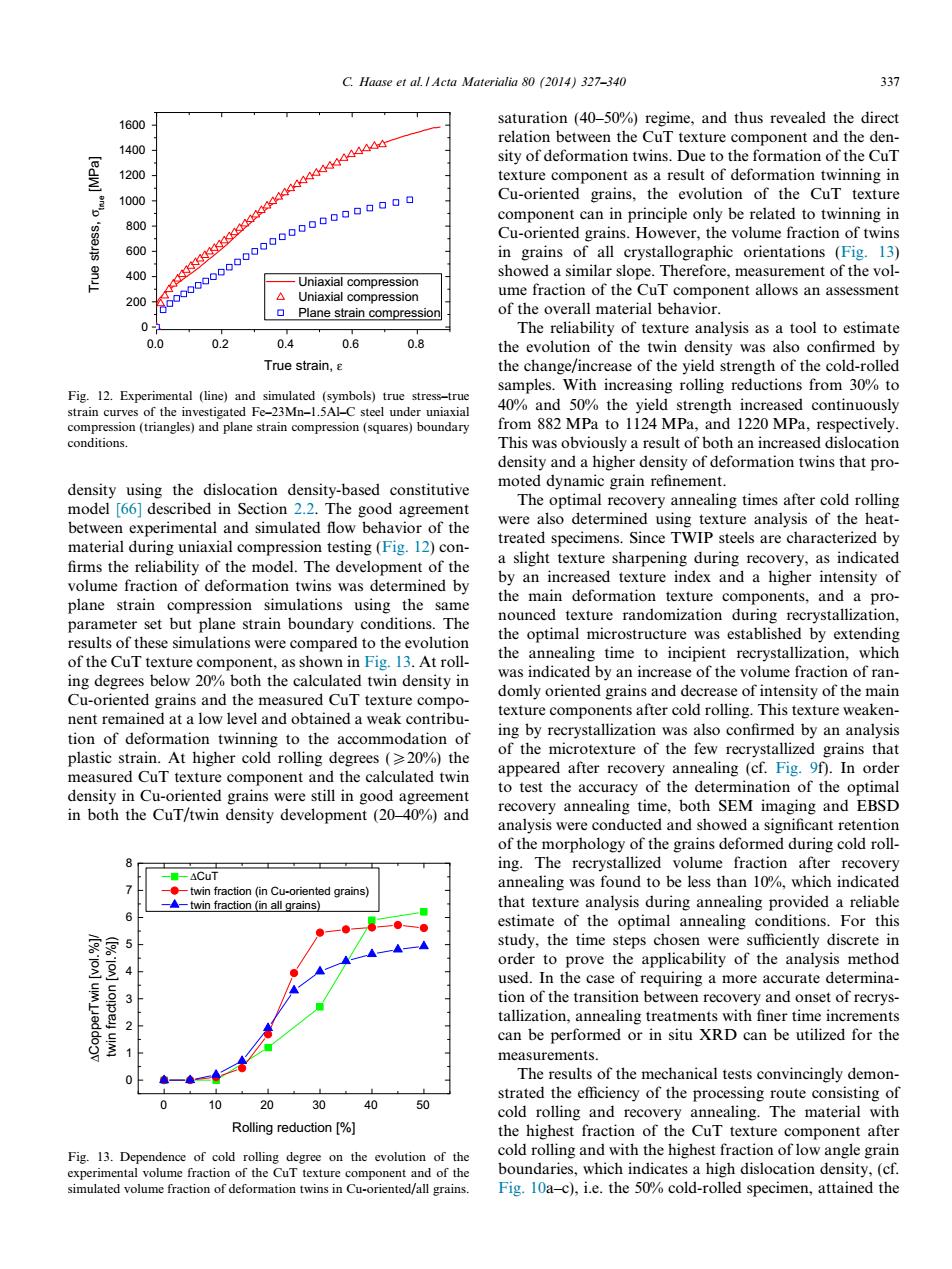

C.Haase et al.Acta Materialia 80 (2014)327-340 337 1600 saturation (40-50%)regime,and thus revealed the direct relation between the CuT texture component and the den- 1400 sity of deformation twins.Due to the formation of the CuT 1200 texture component as a result of deformation twinning in 1000 Cu-oriented grains,the evolution of the CuT texture 8∞00000000000600000口口口口口口 component can in principle only be related to twinning in 800 Cu-oriented grains.However,the volume fraction of twins 600 水sK水eoda444 in grains of all crystallographic orientations (Fig.13) 400 showed a similar slope.Therefore,measurement of the vol- Uniaxial compression ume fraction of the CuT component allows an assessment 200 △ Uniaxial compression 口 Plane strain compression of the overall material behavior. 0 The reliability of texture analysis as a tool to estimate 0.0 0.2 0.4 0.6 0.8 the evolution of the twin density was also confirmed by True strain,e the change/increase of the yield strength of the cold-rolled samples.With increasing rolling reductions from 30%to Fig.12.Experimental (line)and simulated (symbols)true stress-true strain curves of the investigated Fe-23Mn-1.5Al-C steel under uniaxial 40%and 50%the yield strength increased continuously compression(triangles)and plane strain compression(squares)boundary from 882 MPa to 1124 MPa,and 1220 MPa,respectively. conditions. This was obviously a result of both an increased dislocation density and a higher density of deformation twins that pro- density using the dislocation density-based constitutive moted dynamic grain refinement. model [66]described in Section 2.2.The good agreement The optimal recovery annealing times after cold rolling between experimental and simulated flow behavior of the were also determined using texture analysis of the heat- material during uniaxial compression testing(Fig.12)con- treated specimens.Since TWIP steels are characterized by firms the reliability of the model.The development of the a slight texture sharpening during recovery,as indicated by an increased texture index and a higher intensity of volume fraction of deformation twins was determined by plane strain compression simulations using the same the main deformation texture components,and a pro- parameter set but plane strain boundary conditions.The nounced texture randomization during recrystallization, results of these simulations were compared to the evolution the optimal microstructure was established by extending of the CuT texture component,as shown in Fig.13.At roll- the annealing time to incipient recrystallization,which was indicated by an increase of the volume fraction of ran- ing degrees below 20%both the calculated twin density in Cu-oriented grains and the measured CuT texture compo- domly oriented grains and decrease of intensity of the main nent remained at a low level and obtained a weak contribu- texture components after cold rolling.This texture weaken- ing by recrystallization was also confirmed by an analysis tion of deformation twinning to the accommodation of plastic strain.At higher cold rolling degrees (20%)the of the microtexture of the few recrystallized grains that measured CuT texture component and the calculated twin appeared after recovery annealing(cf.Fig.9f).In order density in Cu-oriented grains were still in good agreement to test the accuracy of the determination of the optimal in both the CuT/twin density development (20-40%)and recovery annealing time,both SEM imaging and EBSD analysis were conducted and showed a significant retention of the morphology of the grains deformed during cold roll- ing.The recrystallized volume fraction after recovery -ACUT -twin fraction(in Cu-oriented grains) annealing was found to be less than 10%,which indicated -twin fraction (in all grains) that texture analysis during annealing provided a reliable estimate of the optimal annealing conditions.For this 5 study,the time steps chosen were sufficiently discrete in order to prove the applicability of the analysis method 4 used.In the case of requiring a more accurate determina- 3 tion of the transition between recovery and onset of recrys- tallization,annealing treatments with finer time increments can be performed or in situ XRD can be utilized for the measurements. The results of the mechanical tests convincingly demon- strated the efficiency of the processing route consisting of 10 20 30 40 50 cold rolling and recovery annealing.The material with Rolling reduction [% the highest fraction of the CuT texture component after Fig.13.Dependence of cold rolling degree on the evolution of the cold rolling and with the highest fraction of low angle grain experimental volume fraction of the CuT texture component and of the boundaries,which indicates a high dislocation density,(cf. simulated volume fraction of deformation twins in Cu-oriented/all grains. Fig.10a-c),i.e.the 50%cold-rolled specimen,attained thedensity using the dislocation density-based constitutive model [66] described in Section 2.2. The good agreement between experimental and simulated flow behavior of the material during uniaxial compression testing (Fig. 12) con- firms the reliability of the model. The development of the volume fraction of deformation twins was determined by plane strain compression simulations using the same parameter set but plane strain boundary conditions. The results of these simulations were compared to the evolution of the CuT texture component, as shown in Fig. 13. At rolling degrees below 20% both the calculated twin density in Cu-oriented grains and the measured CuT texture component remained at a low level and obtained a weak contribution of deformation twinning to the accommodation of plastic strain. At higher cold rolling degrees (P20%) the measured CuT texture component and the calculated twin density in Cu-oriented grains were still in good agreement in both the CuT/twin density development (20–40%) and saturation (40–50%) regime, and thus revealed the direct relation between the CuT texture component and the density of deformation twins. Due to the formation of the CuT texture component as a result of deformation twinning in Cu-oriented grains, the evolution of the CuT texture component can in principle only be related to twinning in Cu-oriented grains. However, the volume fraction of twins in grains of all crystallographic orientations (Fig. 13) showed a similar slope. Therefore, measurement of the volume fraction of the CuT component allows an assessment of the overall material behavior. The reliability of texture analysis as a tool to estimate the evolution of the twin density was also confirmed by the change/increase of the yield strength of the cold-rolled samples. With increasing rolling reductions from 30% to 40% and 50% the yield strength increased continuously from 882 MPa to 1124 MPa, and 1220 MPa, respectively. This was obviously a result of both an increased dislocation density and a higher density of deformation twins that promoted dynamic grain refinement. The optimal recovery annealing times after cold rolling were also determined using texture analysis of the heattreated specimens. Since TWIP steels are characterized by a slight texture sharpening during recovery, as indicated by an increased texture index and a higher intensity of the main deformation texture components, and a pronounced texture randomization during recrystallization, the optimal microstructure was established by extending the annealing time to incipient recrystallization, which was indicated by an increase of the volume fraction of randomly oriented grains and decrease of intensity of the main texture components after cold rolling. This texture weakening by recrystallization was also confirmed by an analysis of the microtexture of the few recrystallized grains that appeared after recovery annealing (cf. Fig. 9f). In order to test the accuracy of the determination of the optimal recovery annealing time, both SEM imaging and EBSD analysis were conducted and showed a significant retention of the morphology of the grains deformed during cold rolling. The recrystallized volume fraction after recovery annealing was found to be less than 10%, which indicated that texture analysis during annealing provided a reliable estimate of the optimal annealing conditions. For this study, the time steps chosen were sufficiently discrete in order to prove the applicability of the analysis method used. In the case of requiring a more accurate determination of the transition between recovery and onset of recrystallization, annealing treatments with finer time increments can be performed or in situ XRD can be utilized for the measurements. The results of the mechanical tests convincingly demonstrated the efficiency of the processing route consisting of cold rolling and recovery annealing. The material with the highest fraction of the CuT texture component after cold rolling and with the highest fraction of low angle grain boundaries, which indicates a high dislocation density, (cf. Fig. 10a–c), i.e. the 50% cold-rolled specimen, attained the 0.0 0.2 0.4 0.6 0.8 0 200 400 600 800 1000 1200 1400 1600 True stress, σtrue [MPa] True strain, ε Uniaxial compression Uniaxial compression Plane strain compression Fig. 12. Experimental (line) and simulated (symbols) true stress–true strain curves of the investigated Fe–23Mn–1.5Al–C steel under uniaxial compression (triangles) and plane strain compression (squares) boundary conditions. 0 10 20 30 40 50 0 1 2 3 4 5 6 7 8 ΔCuT twin fraction (in Cu-oriented grains) twin fraction (in all grains) ΔCopperTwin [vol.%]/ twin fraction [vol.%]) Rolling reduction [%] Fig. 13. Dependence of cold rolling degree on the evolution of the experimental volume fraction of the CuT texture component and of the simulated volume fraction of deformation twins in Cu-oriented/all grains. C. Haase et al. / Acta Materialia 80 (2014) 327–340 337