正在加载图片...

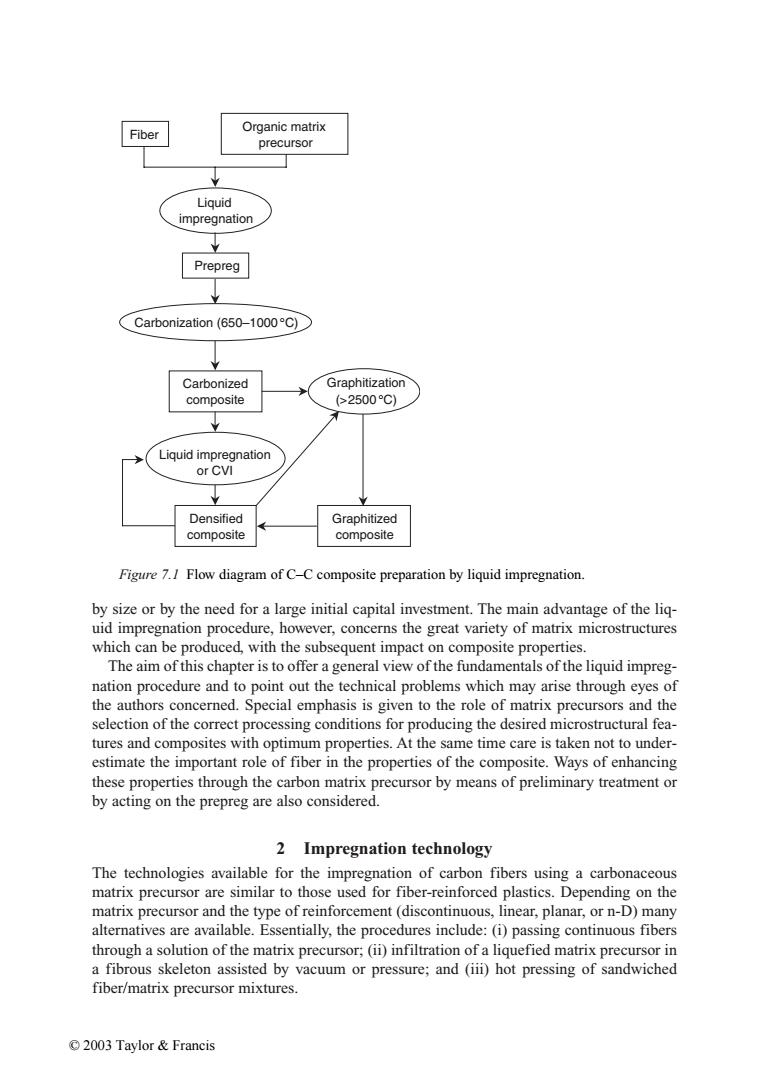

Fiber Organic matrix precursor Liquid impregnation Prepreg Carbonization (650-1000C) Carbonized Graphitization composite (>2500C) Liquid impregnation or CVI Densified Graphitized composite composite Figure 7.I Flow diagram of C-C composite preparation by liquid impregnation. by size or by the need for a large initial capital investment.The main advantage of the liq- uid impregnation procedure,however,concerns the great variety of matrix microstructures which can be produced,with the subsequent impact on composite properties. The aim of this chapter is to offer a general view of the fundamentals of the liquid impreg- nation procedure and to point out the technical problems which may arise through eyes of the authors concerned.Special emphasis is given to the role of matrix precursors and the selection of the correct processing conditions for producing the desired microstructural fea- tures and composites with optimum properties.At the same time care is taken not to under- estimate the important role of fiber in the properties of the composite.Ways of enhancing these properties through the carbon matrix precursor by means of preliminary treatment or by acting on the prepreg are also considered. 2 Impregnation technology The technologies available for the impregnation of carbon fibers using a carbonaceous matrix precursor are similar to those used for fiber-reinforced plastics.Depending on the matrix precursor and the type of reinforcement(discontinuous,linear,planar,or n-D)many alternatives are available.Essentially,the procedures include:(i)passing continuous fibers through a solution of the matrix precursor;(ii)infiltration of a liquefied matrix precursor in a fibrous skeleton assisted by vacuum or pressure;and(iii)hot pressing of sandwiched fiber/matrix precursor mixtures. 2003 Taylor Francisby size or by the need for a large initial capital investment. The main advantage of the liquid impregnation procedure, however, concerns the great variety of matrix microstructures which can be produced, with the subsequent impact on composite properties. The aim of this chapter is to offer a general view of the fundamentals of the liquid impregnation procedure and to point out the technical problems which may arise through eyes of the authors concerned. Special emphasis is given to the role of matrix precursors and the selection of the correct processing conditions for producing the desired microstructural features and composites with optimum properties. At the same time care is taken not to underestimate the important role of fiber in the properties of the composite. Ways of enhancing these properties through the carbon matrix precursor by means of preliminary treatment or by acting on the prepreg are also considered. 2 Impregnation technology The technologies available for the impregnation of carbon fibers using a carbonaceous matrix precursor are similar to those used for fiber-reinforced plastics. Depending on the matrix precursor and the type of reinforcement (discontinuous, linear, planar, or n-D) many alternatives are available. Essentially, the procedures include: (i) passing continuous fibers through a solution of the matrix precursor; (ii) infiltration of a liquefied matrix precursor in a fibrous skeleton assisted by vacuum or pressure; and (iii) hot pressing of sandwiched fiber/matrix precursor mixtures. Figure 7.1 Flow diagram of C–C composite preparation by liquid impregnation. Carbonized composite Densified composite Graphitized composite Liquid impregnation Liquid impregnation or CVI Graphitization (>2500 °C) Carbonization (650–1000 °C) Prepreg Fiber Organic matrix precursor © 2003 Taylor & Francis