正在加载图片...

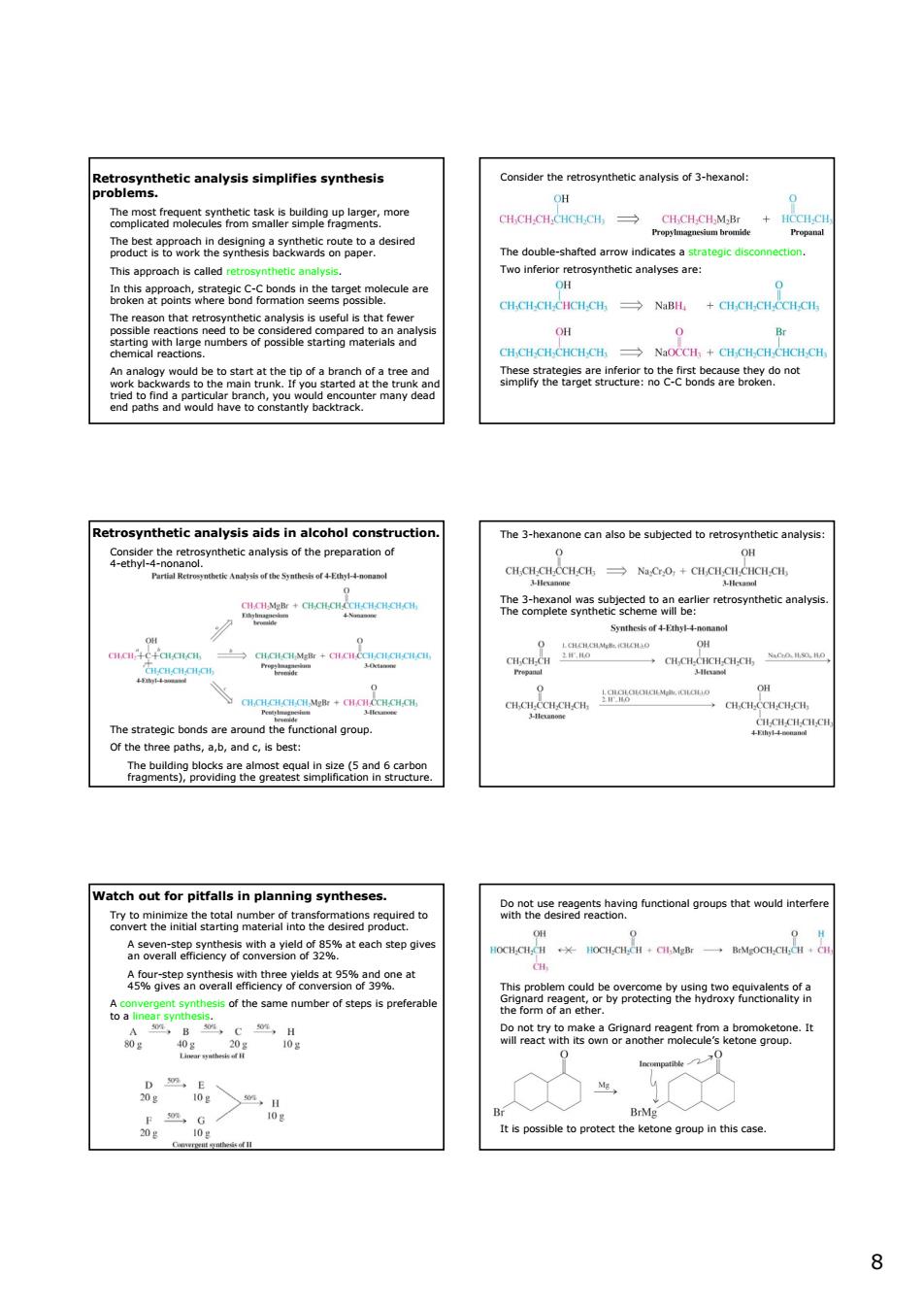

Retrosynthetic analysis simplifies synthesis Consider the retrosynthetic nalyss f 3-hexan: nteanoacteeekSfoboanteanetsmeeauleare 0 B Retrosynthetic analysis aids in alcohol construction The 3-hexanone can also be subjected to retrosynthetic analysis: aanaaw tch out for pitfalls in planning syntheses. XeThemmh9aoalgmmethoeieaetediegeuto 222gR 8”5>a BrMg 88 Retrosynthetic analysis simplifies synthesis problems. The most frequent synthetic task is building up larger, more complicated molecules from smaller simple fragments. The best approach in designing a synthetic route to a desired product is to work the synthesis backwards on paper. This approach is called retrosynthetic analysis. In this approach, strategic C-C bonds in the target molecule are broken at points where bond formation seems possible. The reason that retrosynthetic analysis is useful is that fewer possible reactions need to be considered compared to an analysis starting with large numbers of possible starting materials and chemical reactions. An analogy would be to start at the tip of a branch of a tree and work backwards to the main trunk. If you started at the trunk and tried to find a particular branch, you would encounter many dead end paths and would have to constantly backtrack. Consider the retrosynthetic analysis of 3-hexanol: The double-shafted arrow indicates a strategic disconnection. Two inferior retrosynthetic analyses are: These strategies are inferior to the first because they do not simplify the target structure: no C-C bonds are broken. Retrosynthetic analysis aids in alcohol construction. Consider the retrosynthetic analysis of the preparation of 4-ethyl-4-nonanol. The strategic bonds are around the functional group. Of the three paths, a,b, and c, is best: The building blocks are almost equal in size (5 and 6 carbon fragments), providing the greatest simplification in structure. The 3-hexanone can also be subjected to retrosynthetic analysis: The 3-hexanol was subjected to an earlier retrosynthetic analysis. The complete synthetic scheme will be: Watch out for pitfalls in planning syntheses. Try to minimize the total number of transformations required to convert the initial starting material into the desired product. A seven-step synthesis with a yield of 85% at each step gives an overall efficiency of conversion of 32%. A four-step synthesis with three yields at 95% and one at 45% gives an overall efficiency of conversion of 39%. A convergent synthesis of the same number of steps is preferable to a linear synthesis. Do not use reagents having functional groups that would interfere with the desired reaction. This problem could be overcome by using two equivalents of a Grignard reagent, or by protecting the hydroxy functionality in the form of an ether. Do not try to make a Grignard reagent from a bromoketone. It will react with its own or another molecule’s ketone group. It is possible to protect the ketone group in this case