正在加载图片...

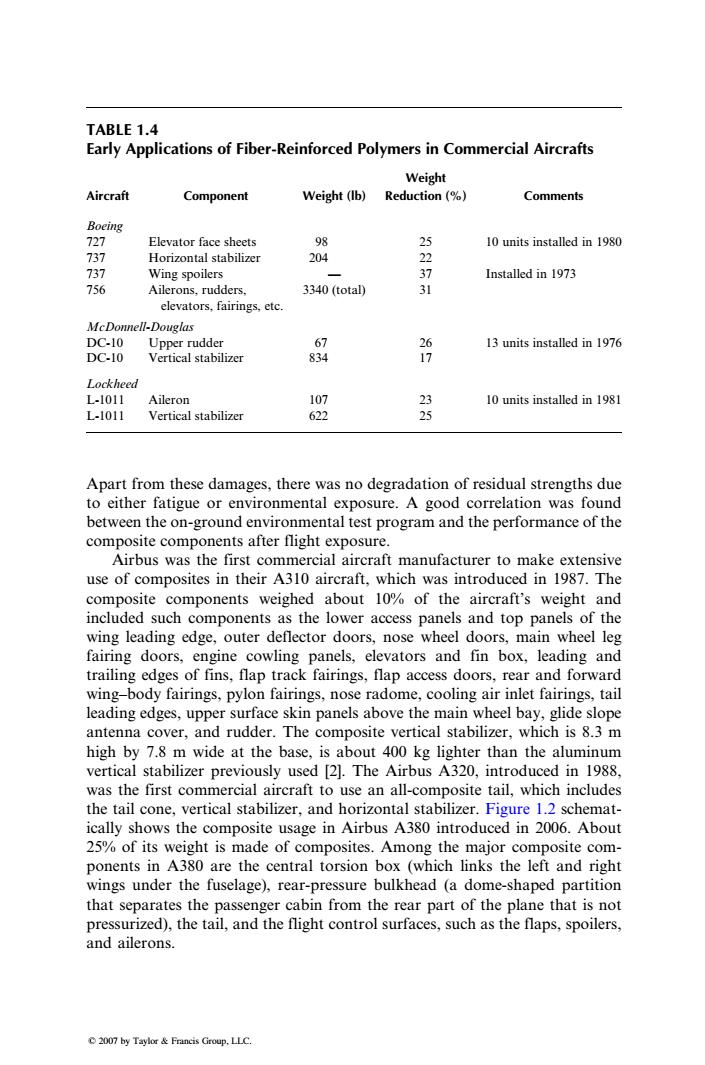

TABLE 1.4 Early Applications of Fiber-Reinforced Polymers in Commercial Aircrafts Weight Aircraft Component Weight(Ib) Reduction (% Comments Boeing 727 Elevator face sheets 98 25 10 units installed in 1980 737 Horizontal stabilizer 204 737 Wing spoilers 3 Installed in 1973 756 Ailerons,rudders. 3340 (total) elevators,fairings,etc. MeDonnell-Douglas DC-10 Upper rudder 67 26 13 units installed in 1976 DC-10 Vertical stabilizer 834 17 Lockheed L-1011 Aileron 107 23 10 units installed in 1981 L-1011 Vertical stabilizer 622 25 Apart from these damages,there was no degradation of residual strengths due to either fatigue or environmental exposure.A good correlation was found between the on-ground environmental test program and the performance of the composite components after flight exposure. Airbus was the first commercial aircraft manufacturer to make extensive use of composites in their A310 aircraft,which was introduced in 1987.The composite components weighed about 10%of the aircraft's weight and included such components as the lower access panels and top panels of the wing leading edge,outer deflector doors,nose wheel doors,main wheel leg fairing doors,engine cowling panels,elevators and fin box,leading and trailing edges of fins,flap track fairings,flap access doors,rear and forward wing-body fairings,pylon fairings,nose radome,cooling air inlet fairings,tail leading edges,upper surface skin panels above the main wheel bay,glide slope antenna cover,and rudder.The composite vertical stabilizer,which is 8.3 m high by 7.8 m wide at the base,is about 400 kg lighter than the aluminum vertical stabilizer previously used [2].The Airbus A320,introduced in 1988, was the first commercial aircraft to use an all-composite tail,which includes the tail cone,vertical stabilizer,and horizontal stabilizer.Figure 1.2 schemat- ically shows the composite usage in Airbus A380 introduced in 2006.About 25%of its weight is made of composites.Among the major composite com- ponents in A380 are the central torsion box (which links the left and right wings under the fuselage),rear-pressure bulkhead (a dome-shaped partition that separates the passenger cabin from the rear part of the plane that is not pressurized),the tail,and the flight control surfaces,such as the flaps,spoilers, and ailerons. 2007 by Taylor Francis Group,LLC.Apart from these damages, there was no degradation of residual strengths due to either fatigue or environmental exposure. A good correlation was found between the on-ground environmental test program and the performance of the composite components after flight exposure. Airbus was the first commercial aircraft manufacturer to make extensive use of composites in their A310 aircraft, which was introduced in 1987. The composite components weighed about 10% of the aircraft’s weight and included such components as the lower access panels and top panels of the wing leading edge, outer deflector doors, nose wheel doors, main wheel leg fairing doors, engine cowling panels, elevators and fin box, leading and trailing edges of fins, flap track fairings, flap access doors, rear and forward wing–body fairings, pylon fairings, nose radome, cooling air inlet fairings, tail leading edges, upper surface skin panels above the main wheel bay, glide slope antenna cover, and rudder. The composite vertical stabilizer, which is 8.3 m high by 7.8 m wide at the base, is about 400 kg lighter than the aluminum vertical stabilizer previously used [2]. The Airbus A320, introduced in 1988, was the first commercial aircraft to use an all-composite tail, which includes the tail cone, vertical stabilizer, and horizontal stabilizer. Figure 1.2 schematically shows the composite usage in Airbus A380 introduced in 2006. About 25% of its weight is made of composites. Among the major composite components in A380 are the central torsion box (which links the left and right wings under the fuselage), rear-pressure bulkhead (a dome-shaped partition that separates the passenger cabin from the rear part of the plane that is not pressurized), the tail, and the flight control surfaces, such as the flaps, spoilers, and ailerons. TABLE 1.4 Early Applications of Fiber-Reinforced Polymers in Commercial Aircrafts Aircraft Component Weight (lb) Weight Reduction (%) Comments Boeing 727 Elevator face sheets 98 25 10 units installed in 1980 737 Horizontal stabilizer 204 22 737 Wing spoilers — 37 Installed in 1973 756 Ailerons, rudders, elevators, fairings, etc. 3340 (total) 31 McDonnell-Douglas DC-10 Upper rudder 67 26 13 units installed in 1976 DC-10 Vertical stabilizer 834 17 Lockheed L-1011 Aileron 107 23 10 units installed in 1981 L-1011 Vertical stabilizer 622 25 2007 by Taylor & Francis Group, LLC