正在加载图片...

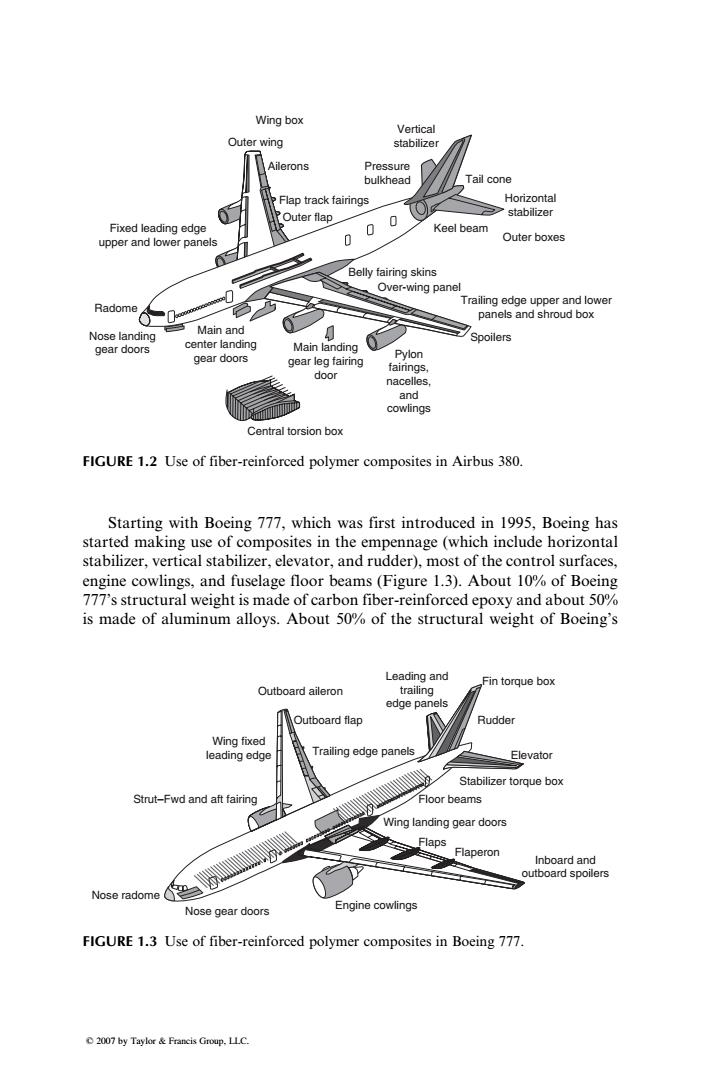

Wing box Vertical Outer wing stabilizer Ailerons Pressure bulkhead Tail cone Flap track fairings Horizontal Outer flap stabilizer Fixed leading edge 0 Keel beam upper and lower panels 0 Outer boxes Belly fairing skins Over-wing panel Radome Trailing edge upper and lower panels and shroud box Nose landing Main and 0 Spoilers gear doors center landing Main landing gear doors gear leg fairing Pylon fairings, door nacelles, and cowlings Central torsion box FIGURE 1.2 Use of fiber-reinforced polymer composites in Airbus 380. Starting with Boeing 777,which was first introduced in 1995,Boeing has started making use of composites in the empennage(which include horizontal stabilizer,vertical stabilizer,elevator,and rudder),most of the control surfaces, engine cowlings,and fuselage floor beams (Figure 1.3).About 10%of Boeing 777's structural weight is made of carbon fiber-reinforced epoxy and about 50% is made of aluminum alloys.About 50%of the structural weight of Boeing's Leading and Fin torque box Outboard aileron trailing edge panels Outboard flap Rudder Wing fixed leading edge Trailing edge panels Elevator Stabilizer torque box Strut-Fwd and aft fairing Floor beams Wing landing gear doors Flaps Flaperon Inboard and outboard spoilers Nose radome Nose gear doors Engine cowlings FIGURE 1.3 Use of fiber-reinforced polymer composites in Boeing 777. 2007 by Taylor Francis Group.LLC.Starting with Boeing 777, which was first introduced in 1995, Boeing has started making use of composites in the empennage (which include horizontal stabilizer, vertical stabilizer, elevator, and rudder), most of the control surfaces, engine cowlings, and fuselage floor beams (Figure 1.3). About 10% of Boeing 777’s structural weight is made of carbon fiber-reinforced epoxy and about 50% is made of aluminum alloys. About 50% of the structural weight of Boeing’s Outer wing Ailerons Flap track fairings Outer flap Radome Fixed leading edge upper and lower panels Main landing gear leg fairing door Main and center landing gear doors Nose landing gear doors Central torsion box Pylon fairings, nacelles, and cowlings Pressure bulkhead Keel beam Tail cone Vertical stabilizer Horizontal stabilizer Outer boxes Over-wing panel Belly fairing skins Trailing edge upper and lower panels and shroud box Spoilers Wing box FIGURE 1.2 Use of fiber-reinforced polymer composites in Airbus 380. Rudder Fin torque box Elevator Stabilizer torque box Floor beams Wing landing gear doors Flaps Flaperon Inboard and outboard spoilers Engine cowlings Nose gear doors Nose radome Strut–Fwd and aft fairing Wing fixed leading edge Outboard aileron Outboard flap Trailing edge panels Leading and trailing edge panels FIGURE 1.3 Use of fiber-reinforced polymer composites in Boeing 777. 2007 by Taylor & Francis Group, LLC