正在加载图片...

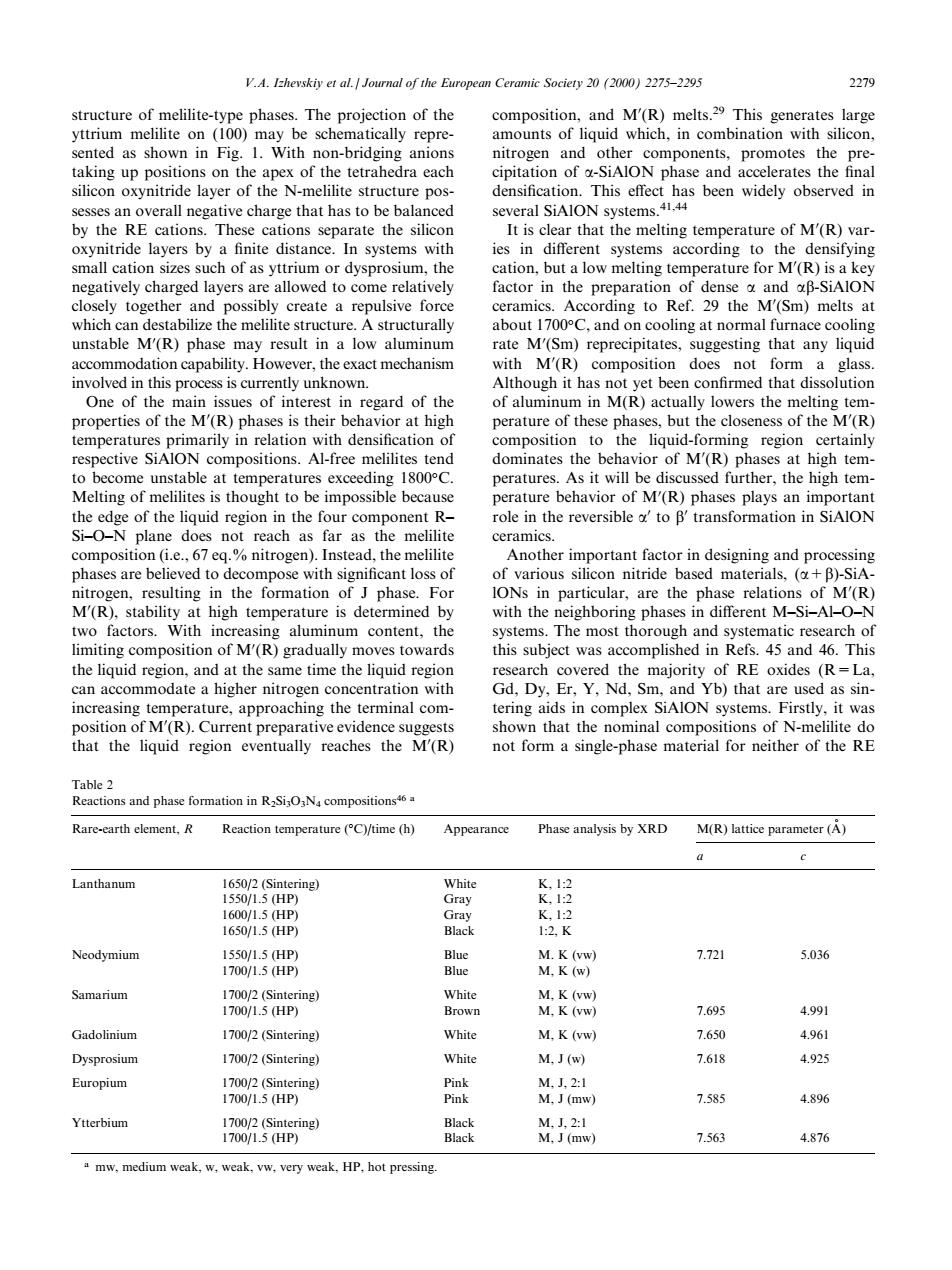

VA.Ihevskiy et al.Jourmal of the Europem Ceramic Society 2(20)2275-295 27 he ombi sented as shown in Fig.1.With non-bridging anions nitrogen and other components,promotes the pre been widely ON by the RE cations.These cations separate the silicon ies in different systems according to the densifying ton siz ch of as dysprosium,th bu which can destabilize the melilite structure.A structurally about 1700C,and on cooling at normal furnace cooling rate M'(Sm)reprecipitates,suggesting that any liquic e exact mechanism compo on es no orm One of the main issues of interest in regard of the of aluminum in M(R)actually lowers the melting tem properties of the M(R)phases is their behavior at high perature of these phases,but the closeness of the M'(R) regio to become nstable at temperatures exceeding 1800 Melting of melilites is thought to be impossible because perature behavior of M(R)phases plays an important the edge of the liquid region in the four component R role in the reversible to B'transformation in SiAlON 6 )Inst the me nother tant factor in designin of various based(B-S IO ture n the se relations of M(R) ot th this subiect was in Refs 4.This the liquid region,and at the same time the liquid region research covered the majority of RE oxides (R-La Gd Dy, Er,Y,Nd m an Yb)that are used as sin othat the nominal co of N-melilite do that the liquid region eventually reaches the M(R) not form a single-phase material for neither of the RE odps6mtoeaRON,eaposas Rare-earth element,R Reaction temperature (C)/time (h) Appearance Phase analysis by XRD M(R)lattice parameter(A) Lanthanum 长 Neodymium 1.721 5.036 Samarium 7.695 491 Gadolinium 1700/2(Sintering】 Whit M.K(vw 7.650 4.961 Dysprosium 170o/2(Sintering】 Whit M.J(w) 7.618 4.925 Europium 7.585 4896 Ytterbium 1e 7.563 4.876 amw.medium weak.w.weak.vw.very weak.HP.hot pressing. structure of melilite-type phases. The projection of the yttrium melilite on (100) may be schematically represented as shown in Fig. 1. With non-bridging anions taking up positions on the apex of the tetrahedra each silicon oxynitride layer of the N-melilite structure possesses an overall negative charge that has to be balanced by the RE cations. These cations separate the silicon oxynitride layers by a ®nite distance. In systems with small cation sizes such of as yttrium or dysprosium, the negatively charged layers are allowed to come relatively closely together and possibly create a repulsive force which can destabilize the melilite structure. A structurally unstable M0 (R) phase may result in a low aluminum accommodation capability. However, the exact mechanism involved in this process is currently unknown. One of the main issues of interest in regard of the properties of the M0 (R) phases is their behavior at high temperatures primarily in relation with densi®cation of respective SiAlON compositions. Al-free melilites tend to become unstable at temperatures exceeding 1800C. Melting of melilites is thought to be impossible because the edge of the liquid region in the four component R± Si±O±N plane does not reach as far as the melilite composition (i.e., 67 eq.% nitrogen). Instead, the melilite phases are believed to decompose with signi®cant loss of nitrogen, resulting in the formation of J phase. For M0 (R), stability at high temperature is determined by two factors. With increasing aluminum content, the limiting composition of M0 (R) gradually moves towards the liquid region, and at the same time the liquid region can accommodate a higher nitrogen concentration with increasing temperature, approaching the terminal composition of M0 (R). Current preparative evidence suggests that the liquid region eventually reaches the M0 (R) composition, and M0 (R) melts.29 This generates large amounts of liquid which, in combination with silicon, nitrogen and other components, promotes the precipitation of a-SiAlON phase and accelerates the ®nal densi®cation. This eect has been widely observed in several SiAlON systems.41,44 It is clear that the melting temperature of M0 (R) varies in dierent systems according to the densifying cation, but a low melting temperature for M0 (R) is a key factor in the preparation of dense a and ab-SiAlON ceramics. According to Ref. 29 the M0 (Sm) melts at about 1700C, and on cooling at normal furnace cooling rate M0 (Sm) reprecipitates, suggesting that any liquid with M0 (R) composition does not form a glass. Although it has not yet been con®rmed that dissolution of aluminum in M(R) actually lowers the melting temperature of these phases, but the closeness of the M0 (R) composition to the liquid-forming region certainly dominates the behavior of M0 (R) phases at high temperatures. As it will be discussed further, the high temperature behavior of M0 (R) phases plays an important role in the reversible a0 to b0 transformation in SiAlON ceramics. Another important factor in designing and processing of various silicon nitride based materials, (a+b)-SiAlONs in particular, are the phase relations of M0 (R) with the neighboring phases in dierent M±Si±Al±O±N systems. The most thorough and systematic research of this subject was accomplished in Refs. 45 and 46. This research covered the majority of RE oxides (R=La, Gd, Dy, Er, Y, Nd, Sm, and Yb) that are used as sintering aids in complex SiAlON systems. Firstly, it was shown that the nominal compositions of N-melilite do not form a single-phase material for neither of the RE Table 2 Reactions and phase formation in R2Si3O3N4 compositions46 a Rare-earth element, R Reaction temperature (C)/time (h) Appearance Phase analysis by XRD M(R) lattice parameter (A ) a c Lanthanum 1650/2 (Sintering) White K, 1:2 1550/1.5 (HP) Gray K, 1:2 1600/1.5 (HP) Gray K, 1:2 1650/1.5 (HP) Black 1:2, K Neodymium 1550/1.5 (HP) Blue M. K (vw) 7.721 5.036 1700/1.5 (HP) Blue M, K (w) Samarium 1700/2 (Sintering) White M, K (vw) 1700/1.5 (HP) Brown M, K (vw) 7.695 4.991 Gadolinium 1700/2 (Sintering) White M, K (vw) 7.650 4.961 Dysprosium 1700/2 (Sintering) White M, J (w) 7.618 4.925 Europium 1700/2 (Sintering) Pink M, J, 2:1 1700/1.5 (HP) Pink M, J (mw) 7.585 4.896 Ytterbium 1700/2 (Sintering) Black M, J, 2:1 1700/1.5 (HP) Black M, J (mw) 7.563 4.876 a mw, medium weak, w, weak, vw, very weak, HP, hot pressing. V.A. Izhevskiy et al. / Journal of the European Ceramic Society 20 (2000) 2275±2295 2279