正在加载图片...

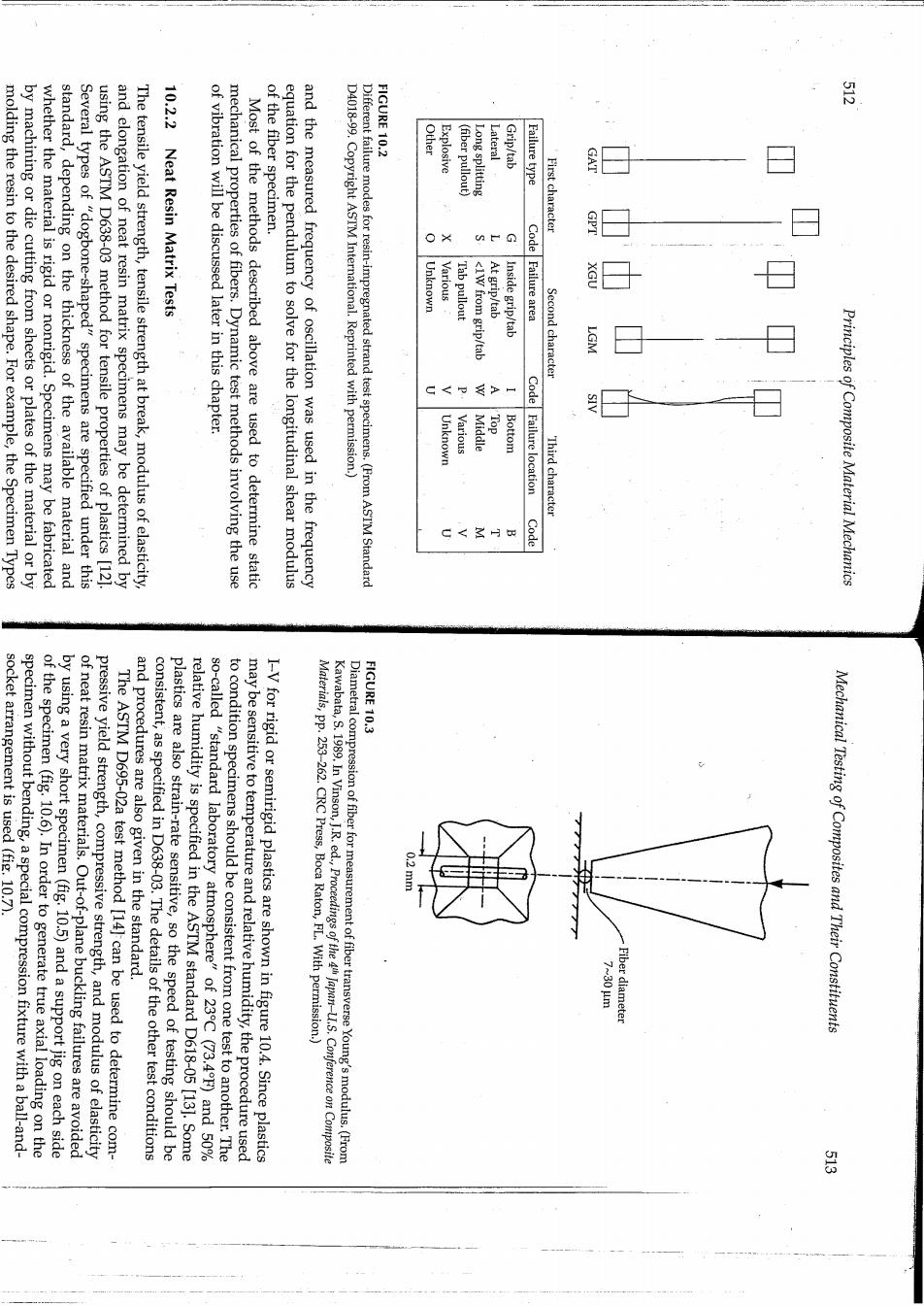

FIGURE 10.2 Other Explosive (fiber pullout) Lateral Grip/tab Failure type GAT 日 molding the resin to the desired shape.For example,the Specimen Types by machining or die cutting from sheets or plates of the material or by whether the material is rigid or nonrigid.Specimens may be fabricated standard,depending on the thickness of the available material and Several types of "dogbone-shaped"specimens are specified under this using the ASTM D638-03 method for tensile properties of plastics [12]. and elongation of neat resin matrix specimens may be determined by The tensile yield strength,tensile strength at break,modulus of elasticity, 10.2.2 Neat Resin Matrix Tests of vibration will be discussed later in this chapter. mechanical properties of fibers.Dynamic test methods involving the use Long splitting Most of the methods described above are used to determine static of the fiber specimen. equation for the pendulum to solve for the longitudinal shear modulus and the measured frequency of oscillation was used in the frequency D4018-99.Copyright ASTM International.Reprinted with permission.) Different failure modes for resin-impregnated strand test specimens.(From ASTM Standard First character GPT Unknown Various Tab pullout <1W from grip/tab At grip/tab Inside grip/tab Code Failure area 日 日 Second character LGM 日 Unknown Various Middle Top Bottom Code Failure location Third character Principles of Composite Material Mechanics socket arrangement is used (fig.10.7). FIGURE 10.3 of the specimen (fig.10.6).In order to generate true axial loading on the specimen without bending,a special compression fixture with a ball-and- by using a very short specimen(fig.10.5)and a support jig on each side of neat resin matrix materials.Out-of-plane buckling failures are avoided pressive yield strength,compressive strength,and modulus of elasticity and procedures are also given in the standard. The ASTM D695-02a test method [14]can be used to determine com- plastics are also strain-rate sensitive,so the speed of testing should be consistent,as specified in D638-03.The details of the other test conditions relative humidity is specified in the ASTM standard D618-05 [13].Some so-called "standard laboratory atmosphere"of 23C (73.4F)and 50% may be sensitive to temperature and relative humidity,the procedure used to condition specimens should be consistent from one test to another.The I-V for rigid or semirigid plastics are shown in figure 10.4.Since plastics Kawabata,S.1989.In Vinson,J.R.ed.,Proceedings of the Japan-U.S.Conference on Composite Materials,Pp.253-262.CRC Press,Boca Raton,FL.With permission.) Diametral compression of fiber for measurement of fiber transverse Young's modulus.(From Mechanical Testing of Composites and Their Constituents 7-30Mm Fiber diameter 器