正在加载图片...

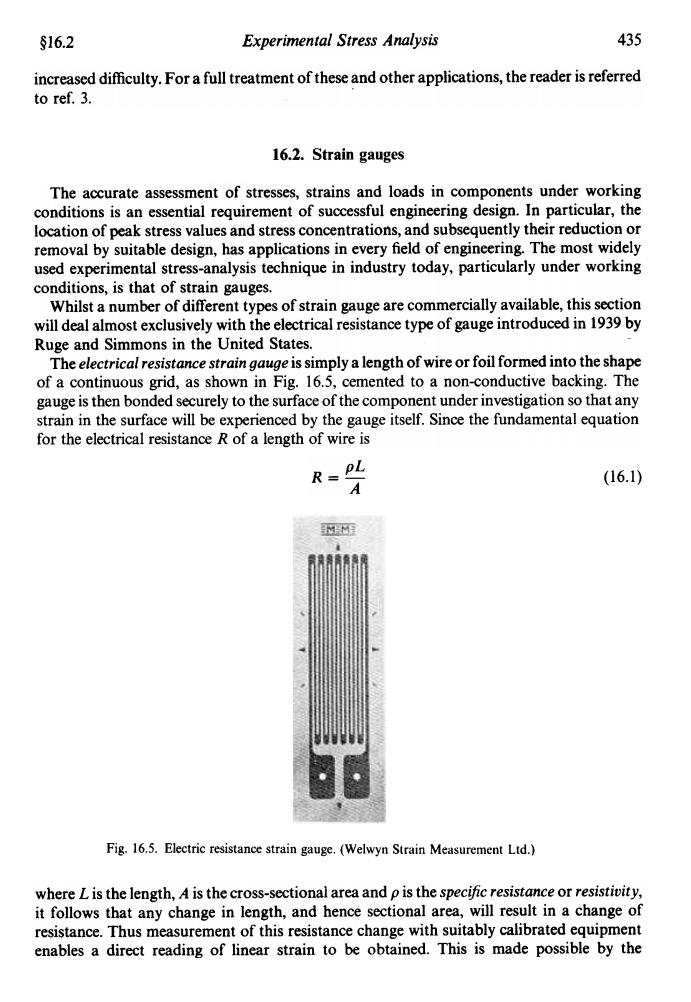

$16.2 Experimental Stress Analysis 435 increased difficulty.For a full treatment of these and other applications,the reader is referred to ref.3. 16.2.Strain gauges The accurate assessment of stresses,strains and loads in components under working conditions is an essential requirement of successful engineering design.In particular,the location of peak stress values and stress concentrations,and subsequently their reduction or removal by suitable design,has applications in every field of engineering.The most widely used experimental stress-analysis technique in industry today,particularly under working conditions,is that of strain gauges. Whilst a number of different types of strain gauge are commercially available,this section will deal almost exclusively with the electrical resistance type of gauge introduced in 1939 by Ruge and Simmons in the United States. The electrical resistance strain gauge is simply a length of wire or foil formed into the shape of a continuous grid,as shown in Fig.16.5,cemented to a non-conductive backing.The gauge is then bonded securely to the surface of the component under investigation so that any strain in the surface will be experienced by the gauge itself.Since the fundamental equation for the electrical resistance R of a length of wire is R= (16.1) A HE Fig.16.5.Electric resistance strain gauge.(Welwyn Strain Measurement Ltd.) where L is the length,A is the cross-sectional area and p is the specific resistance or resistivity, it follows that any change in length,and hence sectional area,will result in a change of resistance.Thus measurement of this resistance change with suitably calibrated equipment enables a direct reading of linear strain to be obtained.This is made possible by theExperimental Stress Analysis 435 §16.2 increased difficulty. For a full treatment of these and other applications, the reader is referred to ref. 3. . 16.2. Strain gauges The accurate assessment of stresses, strains and loads in components under working conditions is an essential requirement of successful engineering design. In particular, the location of peak stress values and stress concentrations, and subsequently their reduction or removal by suitable design, has applications in every field of engineering. The most widely used experimental stress-analysis technique in industry today, particularly under working conditions, is that of strain gauges. Whilst a number of different types of strain gauge are commercially available, this section will deal almost exclusively with the electrical resistance type of gauge introduced in 1939 by Ruge and Simmons in the United States. The electrical resistance strain gauge is simply a length of wire or foil formed into the shape of a continuous grid, as shown in Fig. 16.5, cemented to a non-conductive backing. The gauge is then bonded securely to the surface of the component under investigation so that any strain in the surface will be experienced by the gauge itself. Since the fundamental equation for the electrical resistance R of a length of wire is R=~ A (16.1) Fig. 16.5. Electric resistance strain gauge. (Welwyn Strain Measurement lId.) where L is the length, A is the cross-sectional area and p is the spec!fic resistance or resistivity, it follows that any change in length, and hence sectional area, will result in a change of resistance. Thus measurement of this resistance change with suitably calibrated equipment enables a direct reading of linear strain to be obtained. This is made possible by the